A3 Mk1

|

Servicing rear axle - Four-wheel drive vehicles

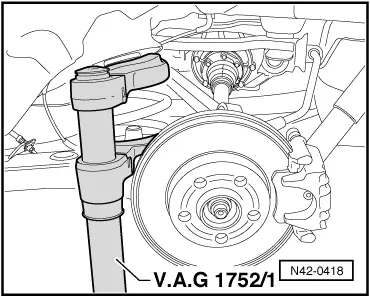

Removing and installing spring

|

|

|

|

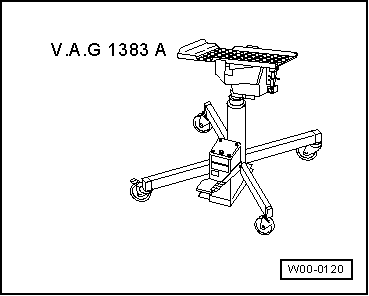

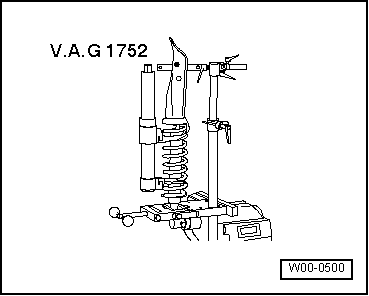

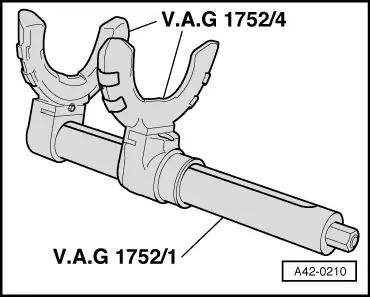

Special tools and workshop equipment required

|

|

|

Safety precautions Extremely high forces occur when tensioning springs. Particular attention is therefore to be paid to the following safety precautions. Attention:

|

|

|

|

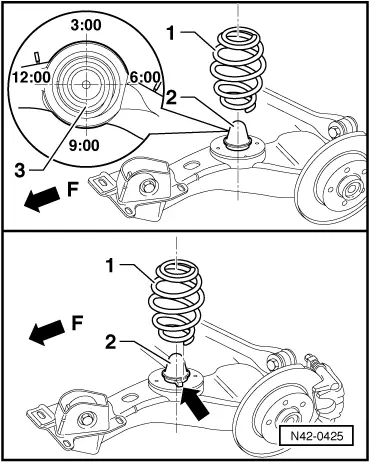

Removing Note: The following description relates to the left spring. The right spring is removed in the same manner.

|

|

|

|

|

|

|

|

|

|

|

|

Attention:

Do not raise vehicle further than necessary to prevent it falling off lifting platform.

|

|

|

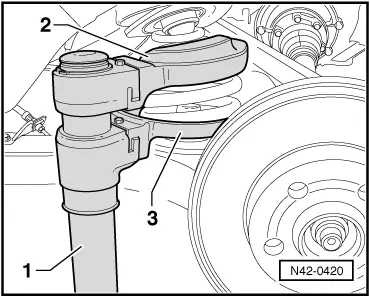

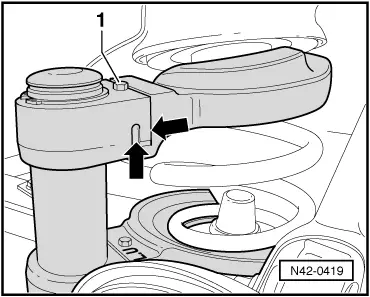

Spring holders will become jammed in spring if spindle is turned too far.

|

|

||||||||||

|

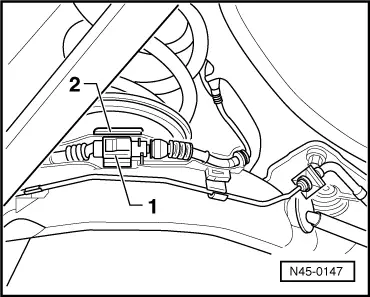

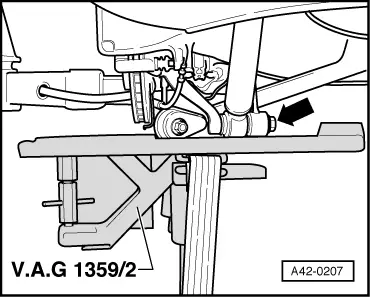

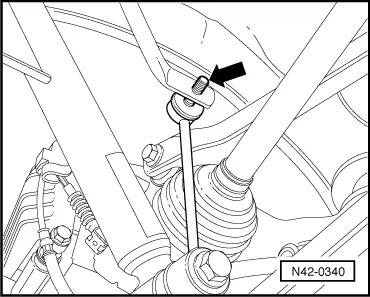

Perform further installation in reverse order, paying attention to the following: Note: → If necessary, unscrew connecting link -arrow- from anti-roll bar. Lower damper bolt is then easier to fit. Tightening torques

1) Replace bolts and nuts Bolted joints with bonded rubber bushes must be tightened when vehicle is standing on its wheels. | ||||||||||