A3 Mk1

|

Servicing rear axle - Four-wheel drive vehicles

Replacing wheel bearing

|

|

|

|

|

|

|

Sequence of operations

|

|

|

Note: Brake hose/pipe is never to be twisted or kinked.

|

|

|

|

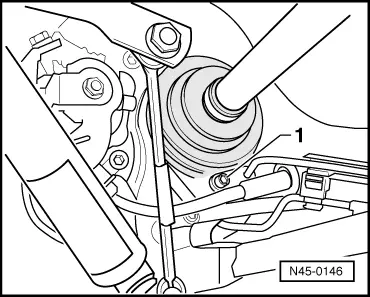

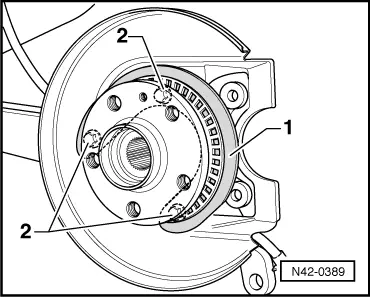

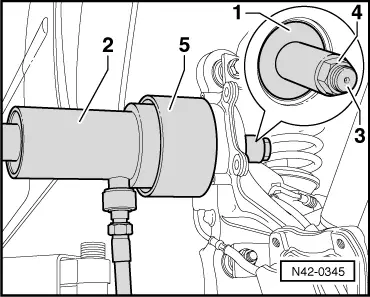

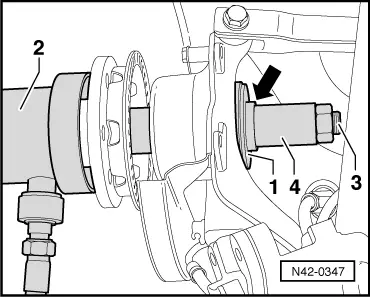

Pressing out wheel hub

Note: Position thrust pad such that it rests completely on bolt heads -2-. |

|

|

|

|

|

Attention:

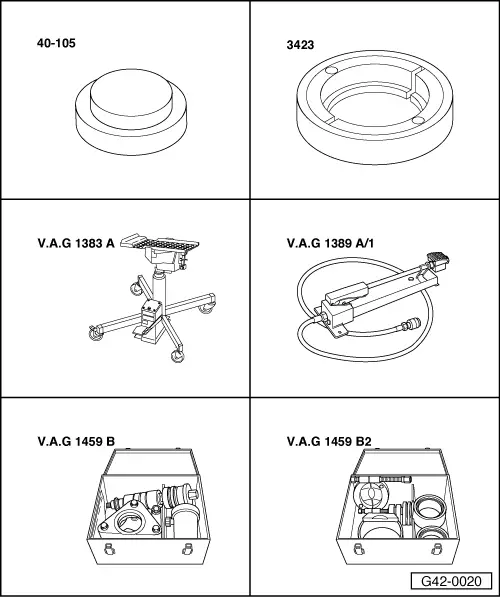

Place engine/gearbox lifter V.A.G 1383

|

|

|

|

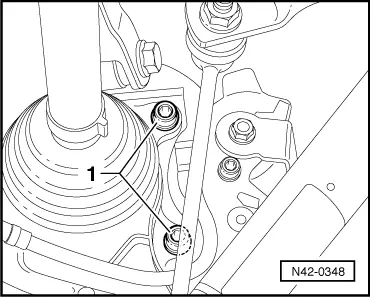

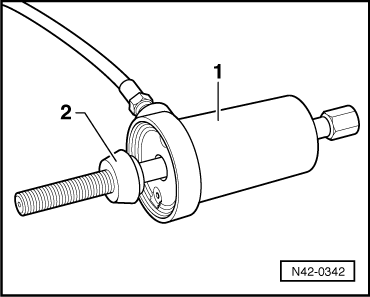

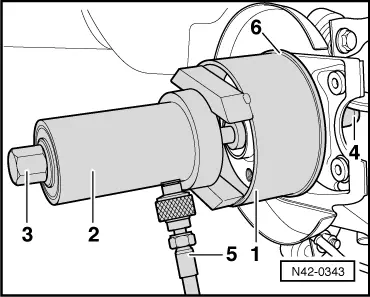

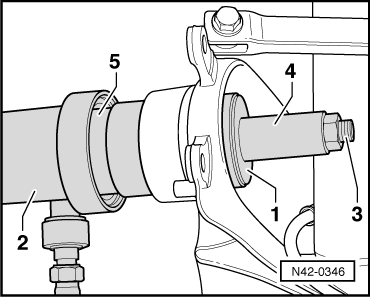

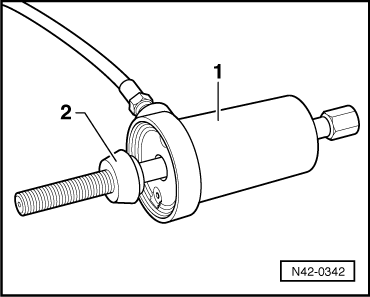

Pressing out wheel bearing

|

|

|

|

|

|

|

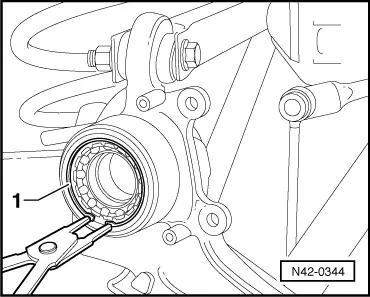

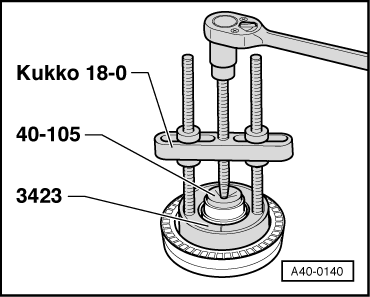

Detaching bearing inner race from wheel hub

|

|

|

|

Pressing in wheel bearing

|

|

|

Pressing in wheel hub

|

|

|

Perform further installation in reverse order, paying attention to the following:

|