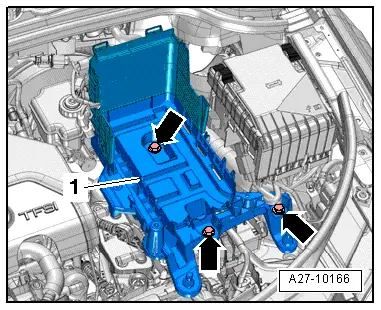

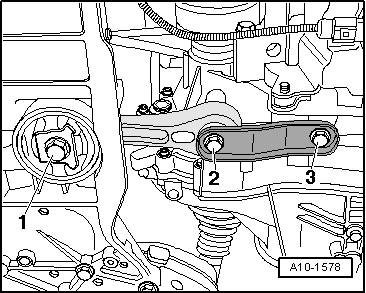

Caution | The threads in the gearbox bracket can be damaged if the bolts are not inserted straight. |

| t

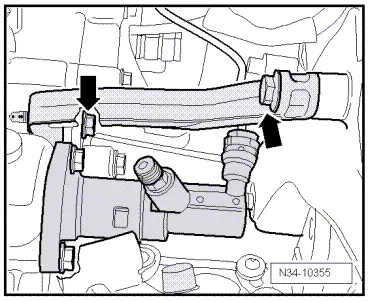

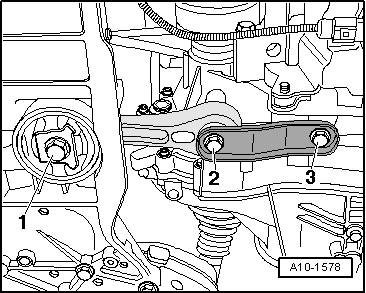

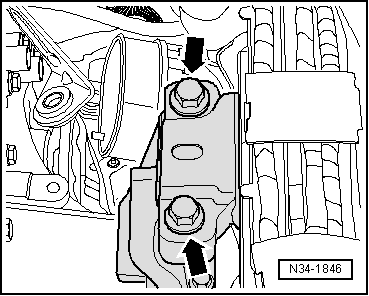

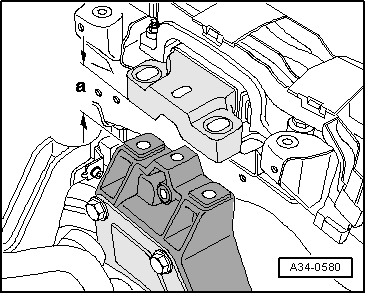

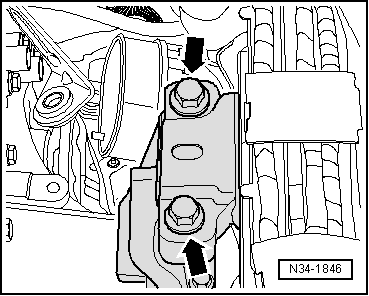

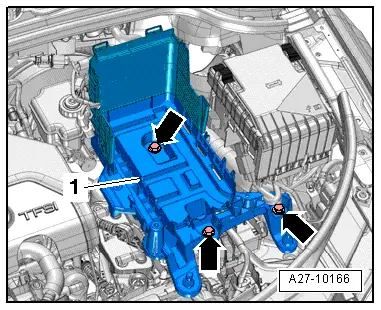

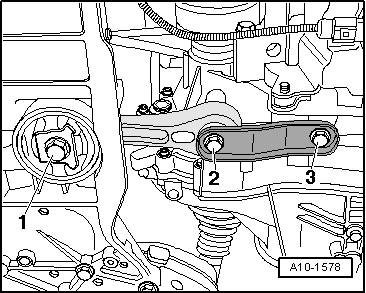

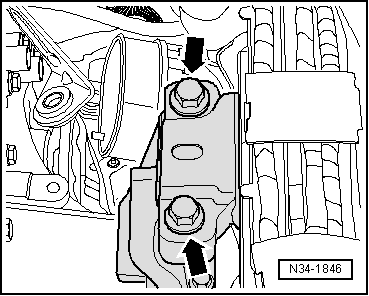

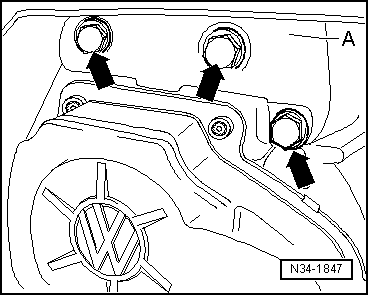

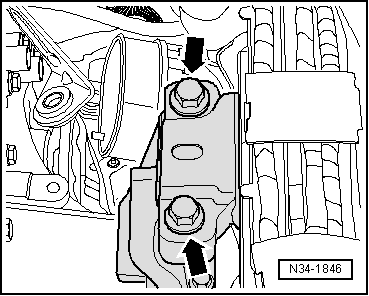

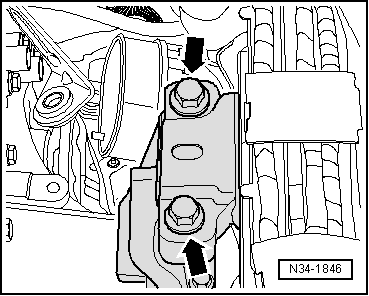

| Before fitting the bolts -arrows-, the gearbox bracket and the support arm of the gearbox mounting must be aligned absolutely parallel. If necessary, push the gearbox up at the rear with a trolley jack. |

| t

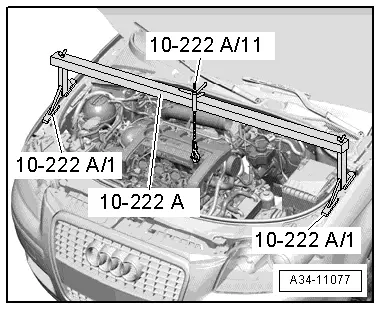

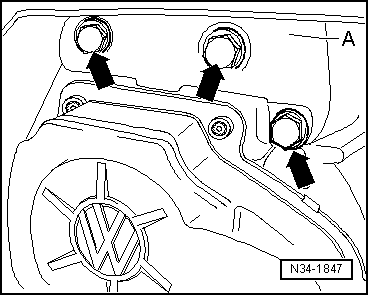

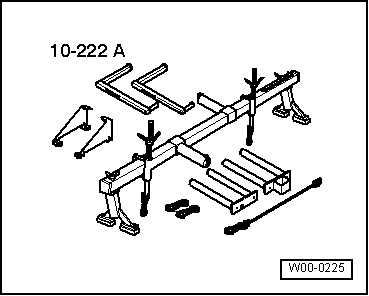

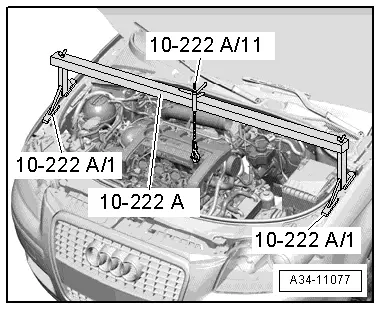

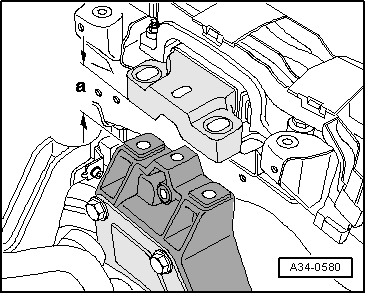

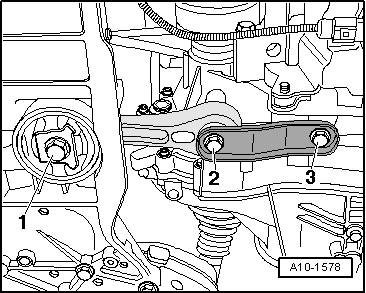

| Do not remove support bracket 10-222A until the bolts securing the engine/gearbox mounting -arrows- have been tightened to the specified torque. |

|

| –

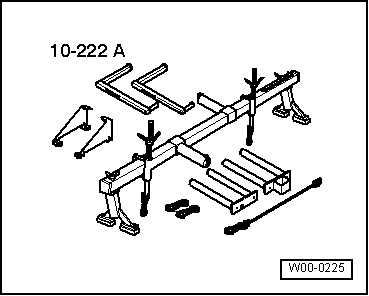

| Pull gearbox up with spindle on support bracket -10 - 222 A- until gearbox bracket contacts support arm of gearbox mounting. |

| –

| Bolt support arm of gearbox mounting onto gearbox bracket using new bolts -arrows-. Tightening torque → Item |

| –

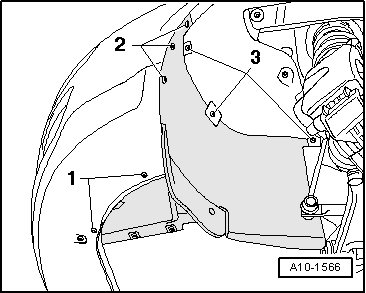

| Detach support bracket -10 - 222 A- from engine. |

|

|

|