| –

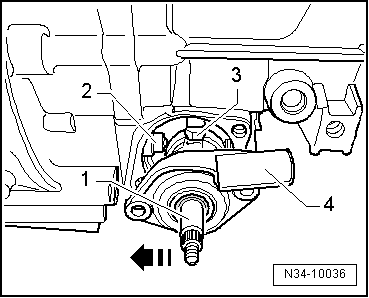

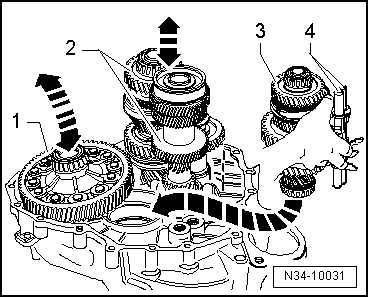

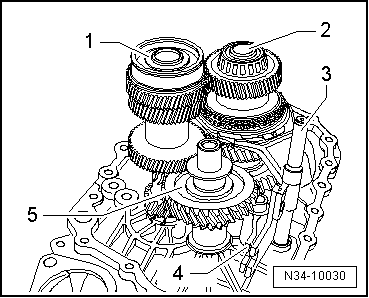

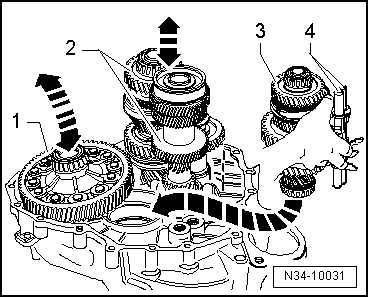

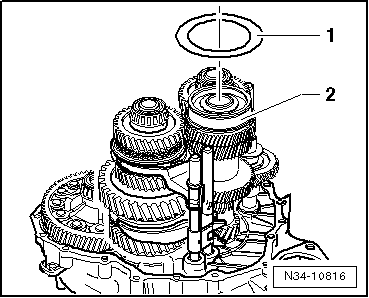

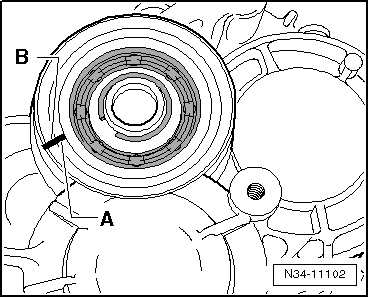

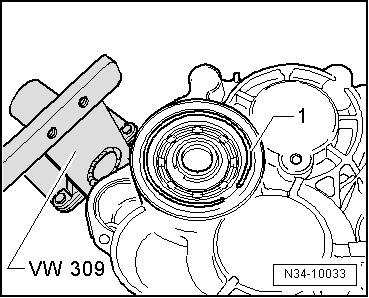

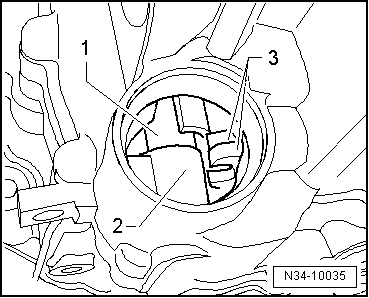

| Then install differential -1-. |

Note | A second mechanic is required for installing the shafts in the clutch housing. |

| –

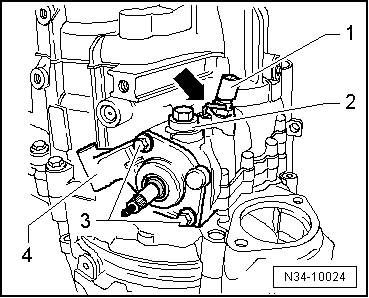

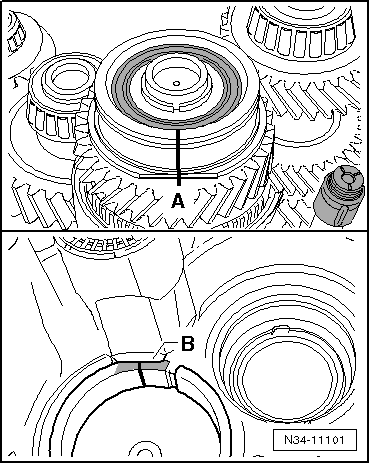

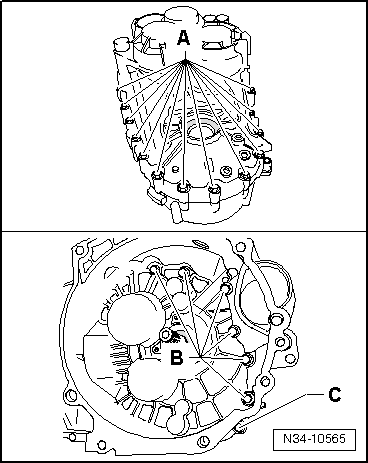

| Take 1st - 4th gear output shaft -3- with selector rods -4- in your right hand as illustrated. |

| –

| Lift differential slightly with your left hand. |

| –

| At the same time, have the second mechanic lift the input shaft and output shaft for 5th, 6th and reverse gear -2- slightly, together with the reverse shaft. |

| –

| Now insert 1st - 4th gear output shaft in direction of -arrow-. |

| l

| The teeth of the input shaft, output shafts and final drive gear/differential must mesh. |

| –

| Now, together with second mechanic, locate shafts and differential in their bearing seats. |

|

|

|

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note