A3 Mk2

| Removing gearbox |

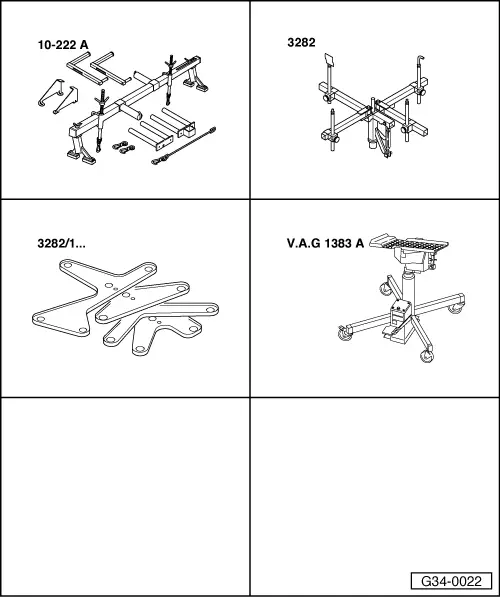

| Special tools and workshop equipment required |

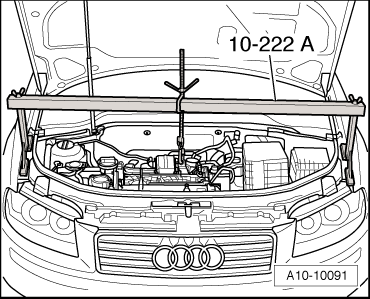

| t | Support bracket -10 - 222 A- |

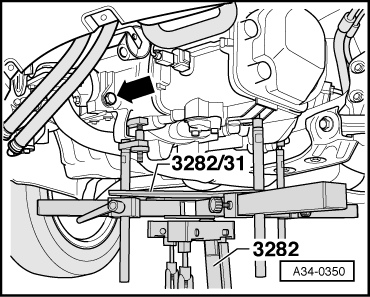

| t | Gearbox support -3282- |

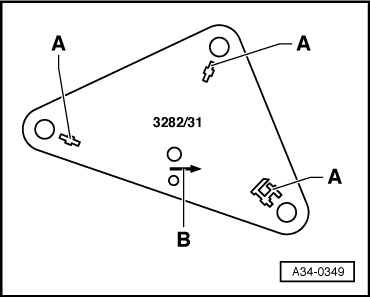

| t | Adjustment plate -3282/31- |

| t | Engine and gearbox jack -V.A.G 1383 A- |

|

|

|

|

Note

Note

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Note

Note |

|

|

|

Note

Note

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Caution

Caution