A3 Mk2

| Removing gearbox - vehicles with 1.2 ltr. TFSI engine |

| Special tools and workshop equipment required |

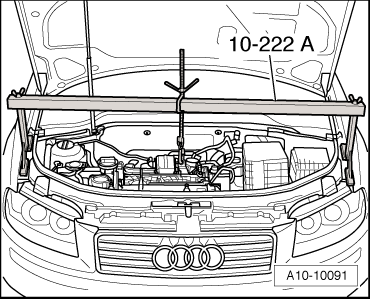

| t | Support bracket -10 - 222 A- |

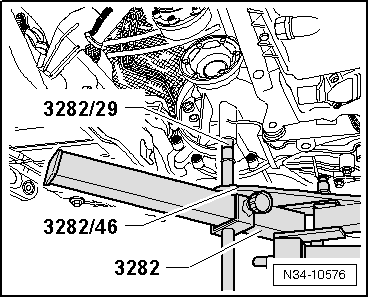

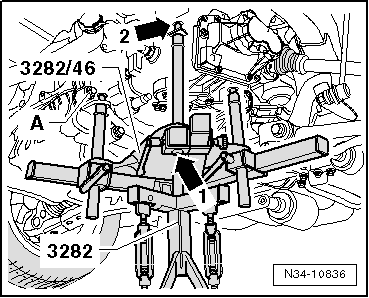

| t | Gearbox support -3282- |

| t | Adjustment plate -3282/46- |

| t | Engine and gearbox jack -V.A.G 1383 A- |

Note

Note

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Note

Note

|

|

Caution

Caution WARNING

WARNING