| –

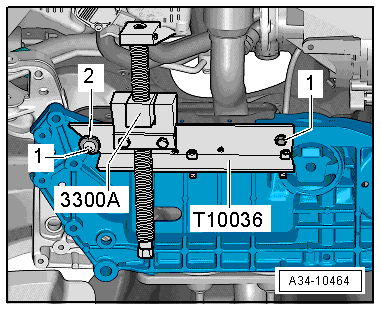

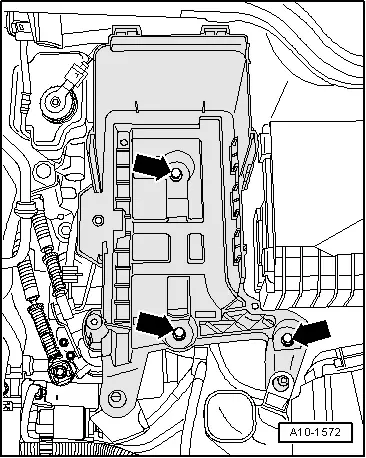

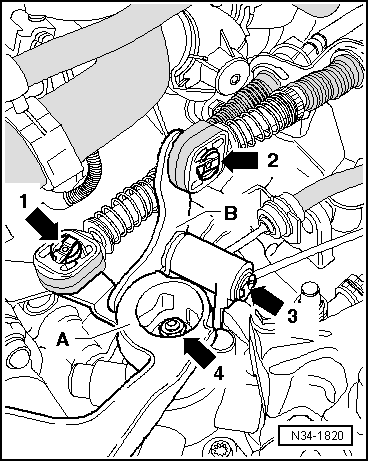

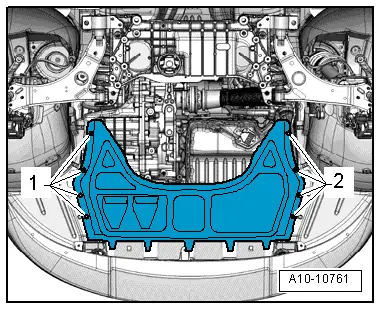

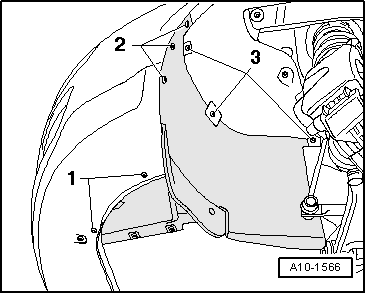

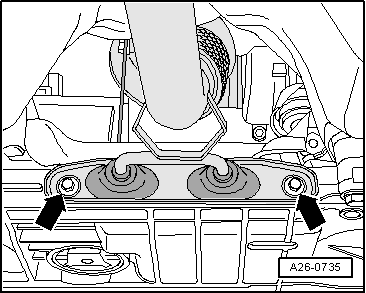

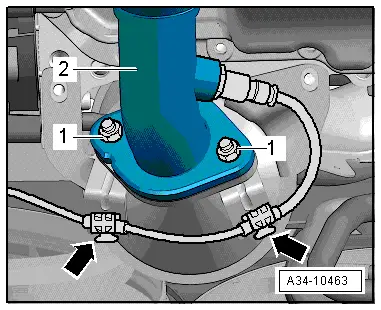

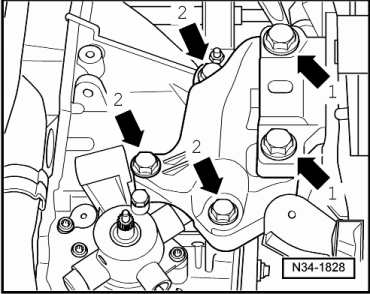

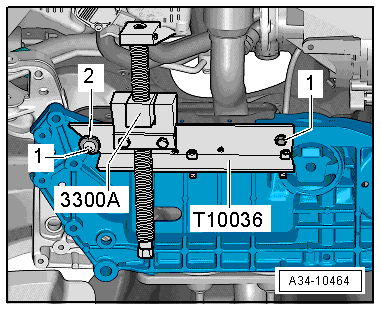

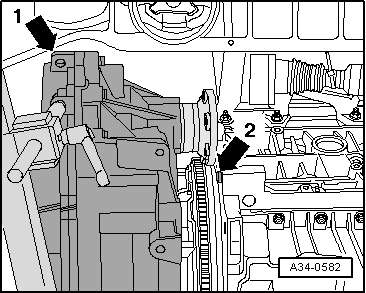

| Secure support -T10036- to subframe, using two M6x20 bolts -1- and one washer -2-. |

| –

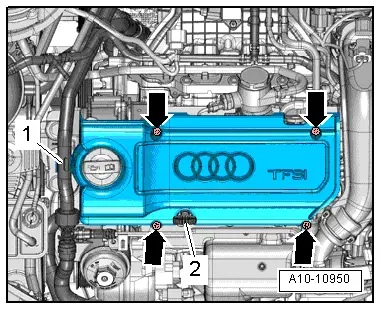

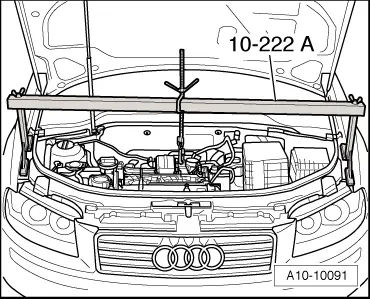

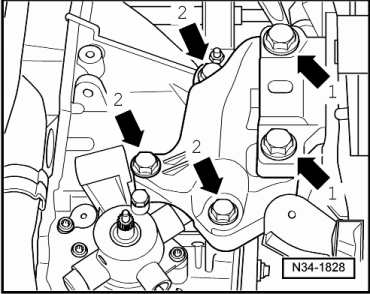

| Secure engine support -3300 A- and push engine to the front, ensuring that there still is enough clearance to radiator cowl. |

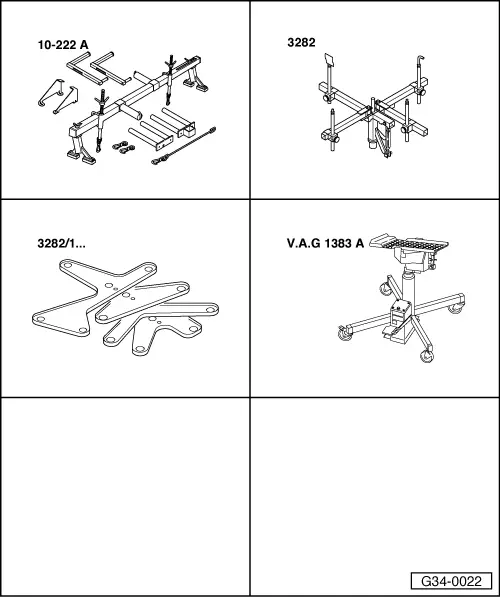

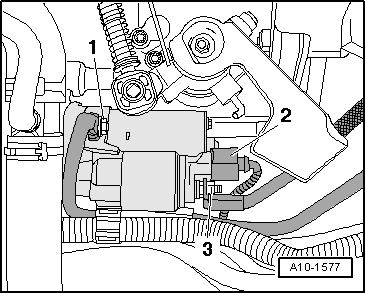

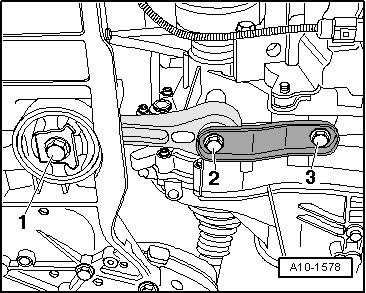

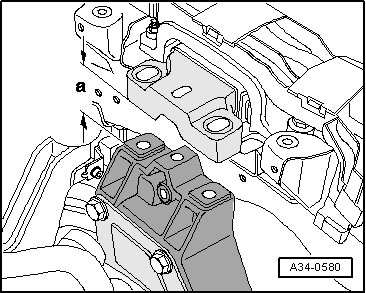

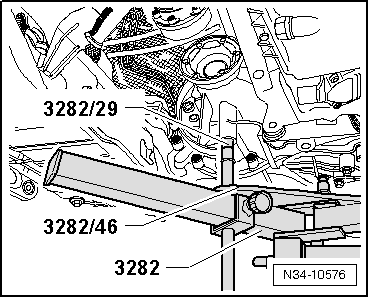

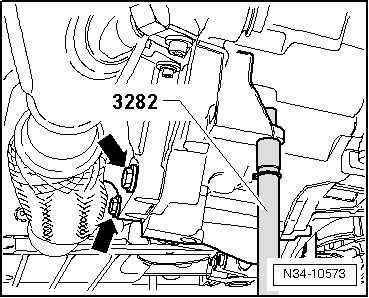

| To remove gearbox “0AJ” set up gearbox support -3282- with adjustment plate -3282/46-. |

| –

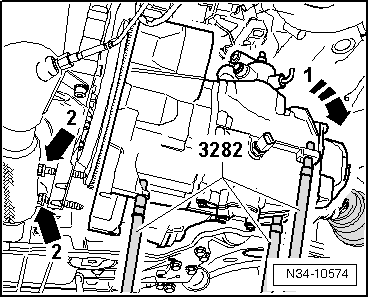

| Insert gearbox support -3282- in engine and gearbox jack -V.A.G 1383 A-. |

| –

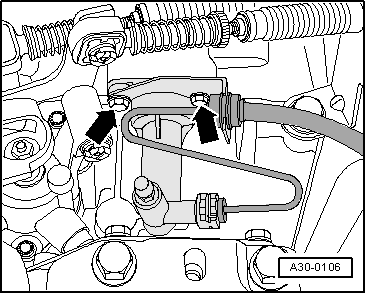

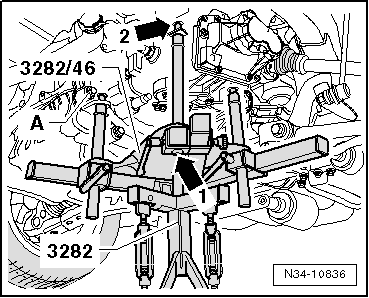

| Place adjustment plate -3282/46- on gearbox support -3282- (adjustment plate only fits in one position). |

| –

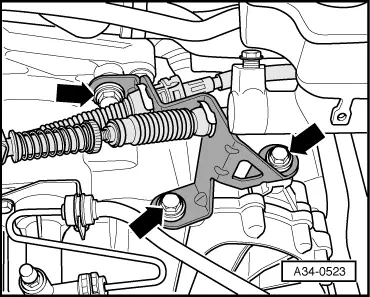

| Align arms of gearbox support according to holes in adjustment plate. |

| –

| Bolt on support elements as illustrated on adjustment plate. |

| –

| Place engine and gearbox jack -V.A.G 1383 A- under vehicle; arrow symbol on adjustment plate points to front of vehicle. |

| –

| Align adjustment plate parallel with gearbox. |

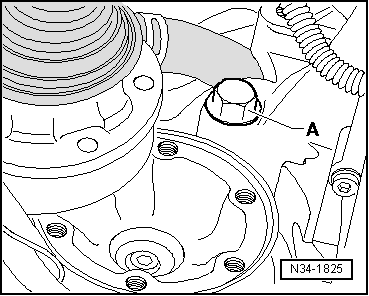

| Pin -arrow 1- (illustration 10836) should be flush with guide of gearbox support. |

|

|

|

Note

Note

Note

Note

Note

Note

WARNING

WARNING