A3 Mk2

Note

Note

|

|

|

|

|

|

|

Note

Note

Note

Note |

|

|

|

|

|

|

|

|

|

|

|

|

|

Note

Note

|

|

|

|

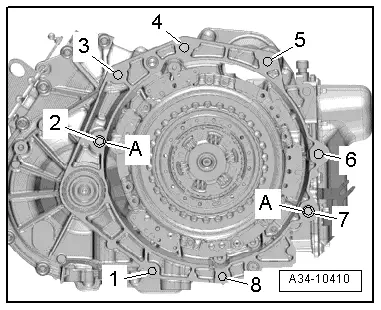

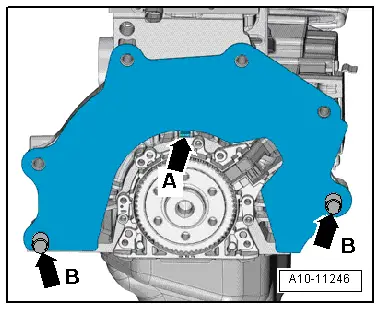

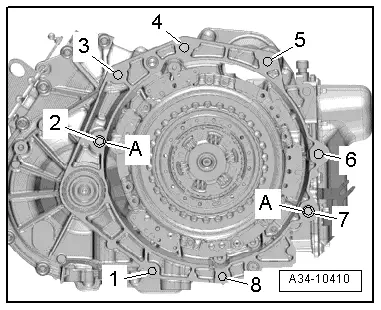

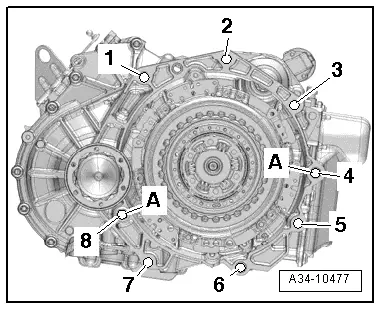

| Item | Bolt | Nm |

| 1, 8 | M10x50 | 40 |

| 2, 6, 7 | M12x65 | 80 |

| 3, 4, 5 | M12x55 | 80 |

| A | Dowel sleeves for centralising | |

|

|

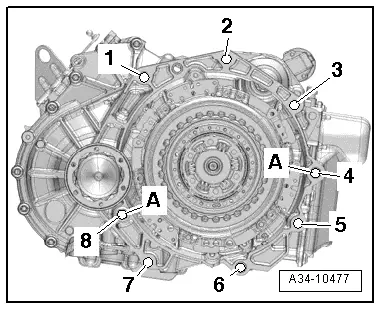

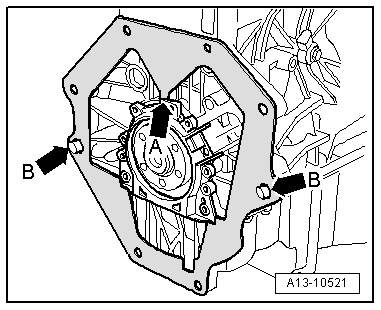

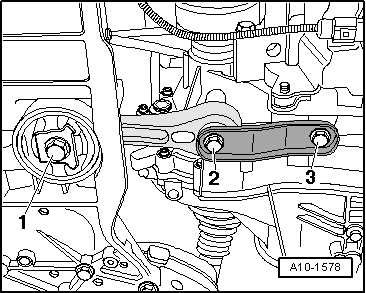

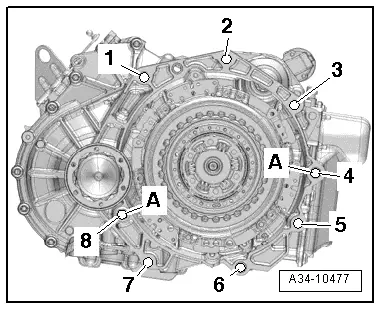

| Item | Bolt | Nm |

| 1, 3 | M12x55 | 80 |

| 2 | M12x170 | 80 |

| 4 | M12x80 | 80 |

| 5, 6, 7 | M10x50 | 40 |

| 8 | M12x90 | 80 |

| A | Dowel sleeves for centralising | |

|

|

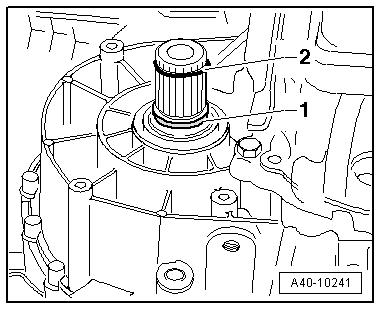

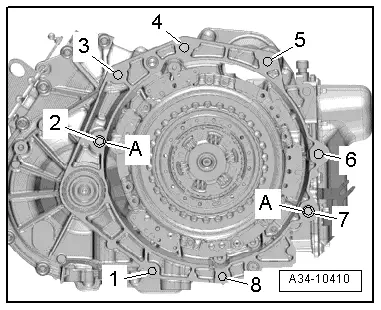

| Item | Bolt | Nm |

| 1, 3 | M12x55 | 80 |

| 2 | M12x155 | 80 |

| 4, 8 | M12x65 | 80 |

| 5 | M12x50 | 80 |

| 6, 7 | M10x50 | 40 |

| A | Dowel sleeves for centralising | |

|

|

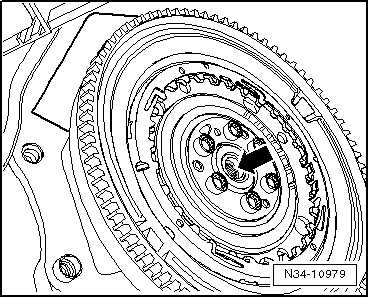

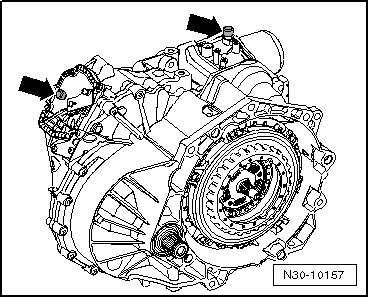

| Item | Bolt | Nm |

| 1, 3, 10 | M12x55 | 80 |

| 5, 9 | M12x70 | 80 |

| 6 … 8 | M10x50 | 40 |

| A | Dowel sleeves for centralising | |

|

Caution

Caution