| –

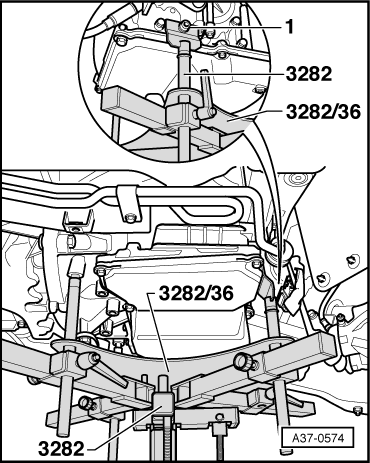

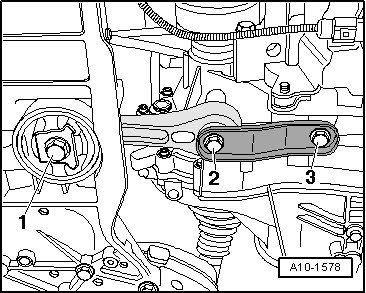

| Install assembly mounting as follows: |

| –

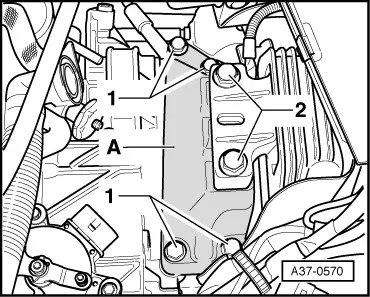

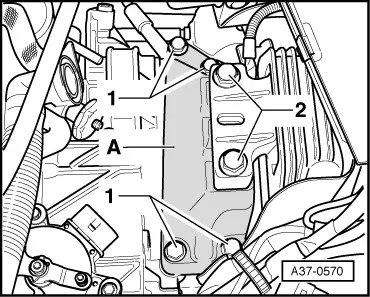

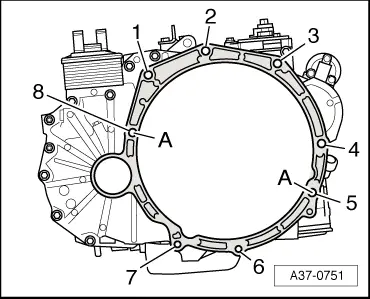

| Place gearbox console -A- between gearbox and gearbox mounting. |

| –

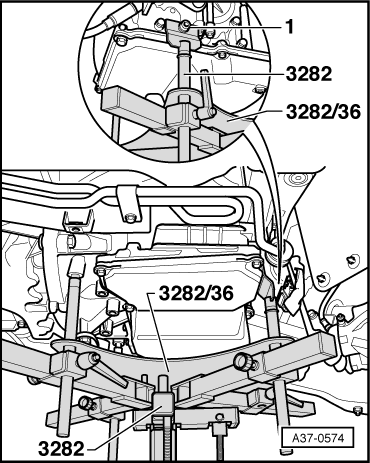

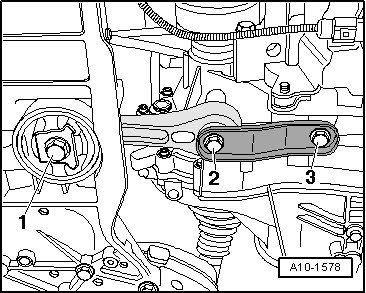

| Pull gearbox up to gearbox support with spindle on support bracket. |

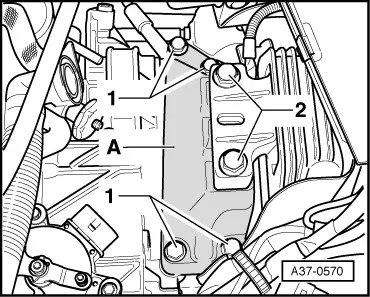

Caution | Before tightening bolts -1- and -2- gearbox mounting and console must be aligned in an absolutely parallel position, otherwise the threads will be damaged. If necessary, push gearbox up at rear with trolley jack. |

|

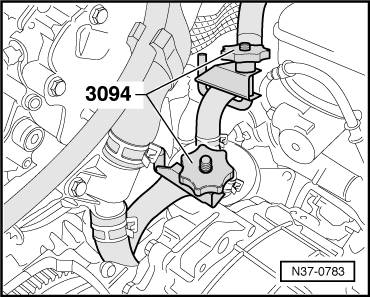

Caution | Support bracket -10-222 A- must not be removed until all bolts on left and right assembly mountings have been tightened to specified torque. |

|

|

|

|

Note!

Note!

Note!

Note!

Note!

Note!

Note!

Note!