A3 Mk2

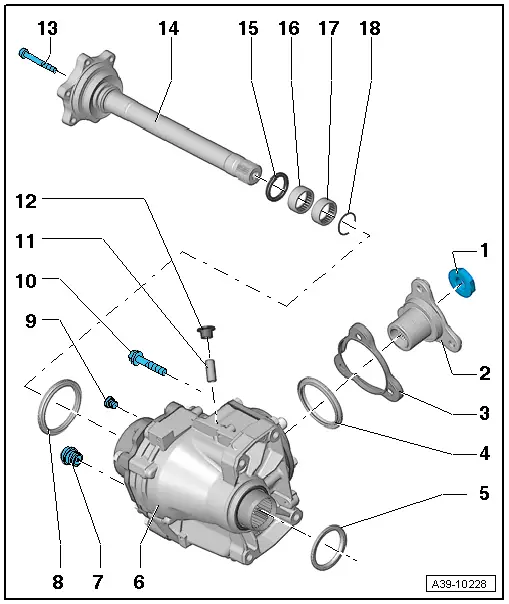

| Exploded view - flange shafts, oil seals |

| 1 - | Hexagon nut |

| q | For output flange |

| q | Renew → Electronic parts catalogue |

| q | 480 Nm |

| 2 - | Output flange on bevel box |

| 3 - | Output flange cap |

| q | Renew only if damaged |

| 4 - | Oil seal |

| q | For output flange on bevel box |

| q | → Chapter „Renewing oil seal for output flange on bevel box“ |

| 5 - | Oil seal |

| q | Between gearbox and bevel box |

| q | → Chapter „Renewing oil seal between gearbox and bevel box (on bevel box)“ |

| 6 - | Bevel box |

| q | Removing and installing → Chapter |

| 7 - | Oil drain plug |

| q | For bevel box |

| q | Tightening torque → Chapter |

| 8 - | Oil seal |

| q |

| 9 - | Filler and inspection plug |

| q | For bevel box |

| q | Tightening torque → Chapter |

| 10 - | Bolt |

| q | Secures bevel box to gearbox |

| q | 4x |

| q | Renew |

| q | 40 Nm + 45° |

| 11 - | Breather pipe |

| 12 - | Breather cap |

| 13 - | Countersunk bolt |

| q | Renew |

| q | 30 Nm |

| 14 - | Flange shaft (right-side) |

| q | → Chapter „Removing and installing flange shaft (right-side)“ |

| 15 - | Oil seal |

| q | Always renew after removing flange shaft (right-side) |

| 16 - | Needle bearing |

| q | Needle bearings (polygon bearings) do not turn easily when flange shaft is removed; this does not indicate a faulty bearing. A test for noisy bearings can only be performed with the bearings installed |

| q | Inspect for signs of damage to bearings (such as cracking in outer race); renew if necessary |

| q | → Chapter „Renewing needle bearings (polygon bearings) for flange shaft (right-side)“ |

| 17 - | Needle bearing |

| q | Needle bearings (polygon bearings) do not turn easily when flange shaft is removed; this does not indicate a faulty bearing. A test for noisy bearings can only be performed with the bearings installed |

| q | Inspect for signs of damage to bearings (such as cracking in outer race); renew if necessary |

| q | → Chapter „Renewing needle bearings (polygon bearings) for flange shaft (right-side)“ |

| 18 - | Circlip |

| q | Renew |

|

|

|

|