A3 Mk2

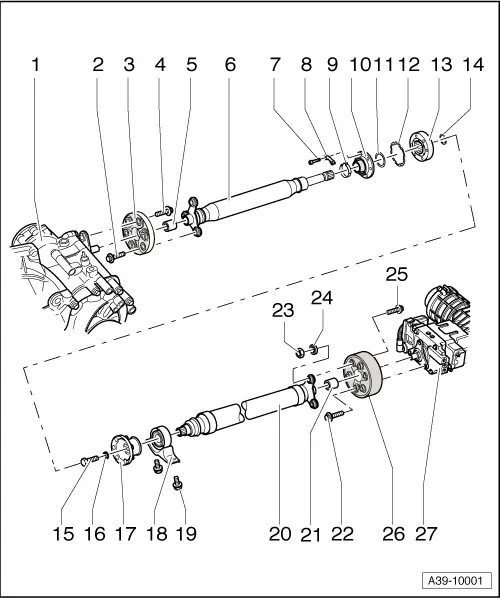

| Servicing propshaft - exploded view of components |

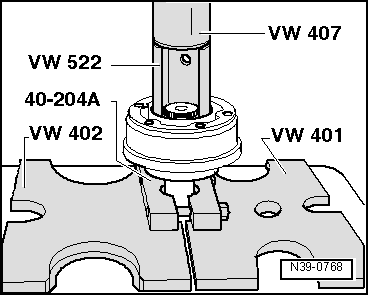

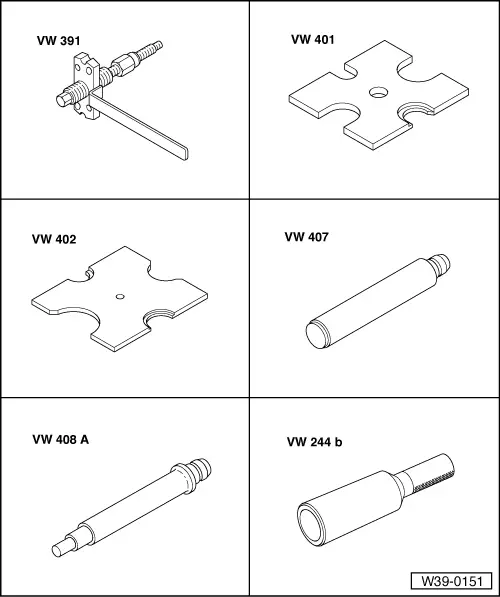

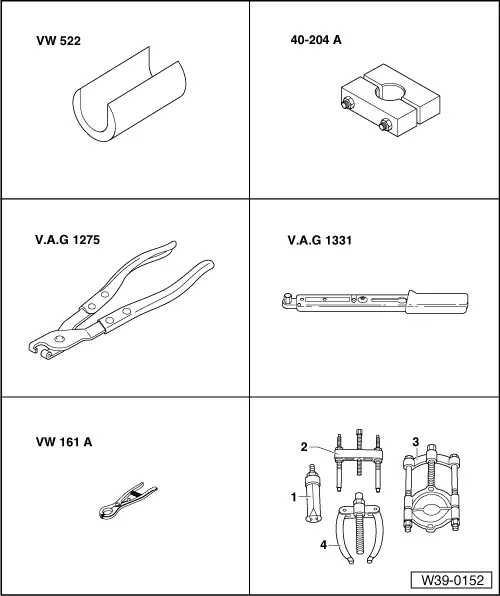

| Special tools and workshop equipment required |

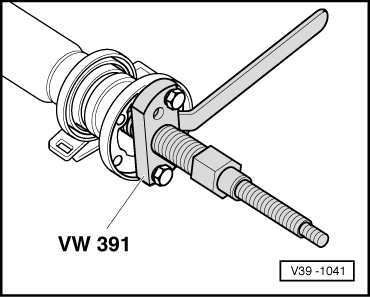

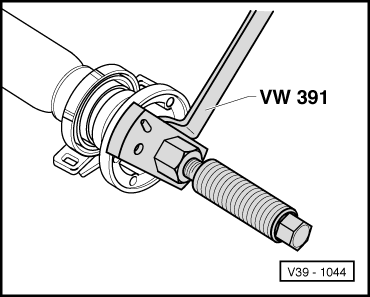

| t | Drive flange installing tool -VW 391- |

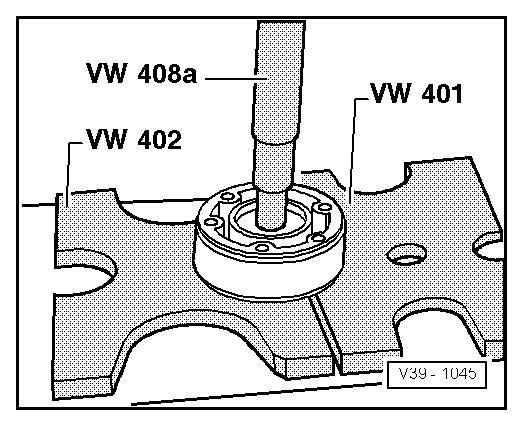

| t | Thrust plate -VW 401- |

| t | Thrust plate -VW 402- |

| t | Press tool -VW 407- |

| t | Press tool -VW 408A- |

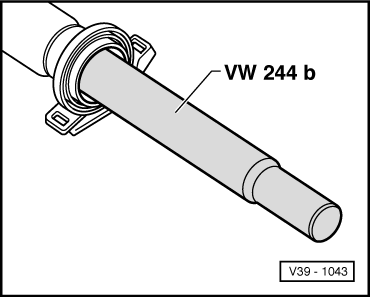

| t | Drift sleeve -VW 244B- |

| t | Support sleeve -VW 522- |

| t | Tensioner -V.A.G 40-204A- |

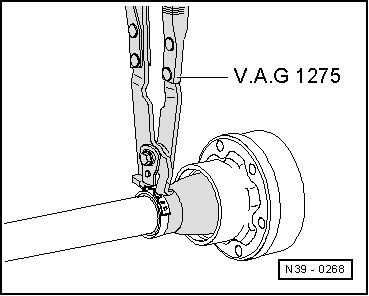

| t | Hose clip pliers -V.A.G 1275/- |

| t | Torque wrench -V.A.G 1331/- |

| t | Circlip pliers -VW 161A- |

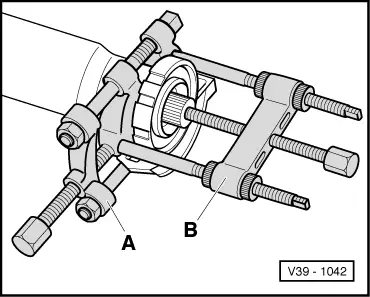

| t | 2 - Kukko 18/0 puller |

| t | 3 - Kukko 17/1 splitter |

|

|

Note

Note

|

|

| 1 - | Manual gearbox with bevel box |

| 2 - | Flange bolt with twelve-point head, 50 Nm and turn 90° further |

| q | Always renew |

| 3 - | Flexible coupling with heat shield |

| q | Installation position: open side of heat shield points towards gearbox |

| q | Removing and installing → Chapter |

| 4 - | Flange bolt with twelve-point head, 60 Nm |

| 5 - | Centring sleeve |

| 6 - | Propshaft tube (front) |

| q | Do not damage centring sleeve -5- and seal in centre of flange when removing and installing |

| 7 - | Socket head bolt, 40 Nm |

| q | Always renew |

| 8 - | Lock plate |

| 9 - | Clip |

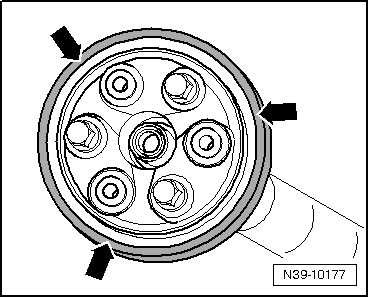

| q | Tensioning → Fig. |

| 10 - | Boot for constant velocity joint |

| q | Drive off with a drift before pressing off CV joint |

| q | Check for damage |

| 11 - | Dished spring |

| q | Inner diameter serrated |

| q | Installation position: large diameter lies against CV joint |

| 12 - | Gasket |

| q | Renew; pull off backing and stick onto joint |

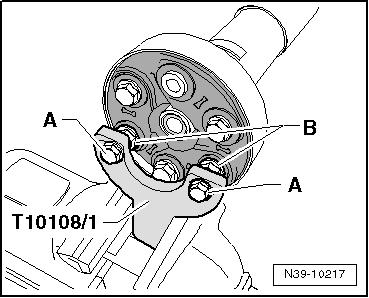

| 13 - | Constant velocity joint |

| q | Pressing off → Fig. |

| q | Pressing on → Fig. |

| q | Press 25 g G-6.3 grease from each side (in total 50 g) into joint. Regrease joint if necessary when renewing boot |

| 14 - | Circlip |

| q | Renew |

| q | Remove and install using circlip pliers -VW 161A- |

| 15 - | Hexagon bolt, 45 Nm |

| 16 - | Washer |

| q | Always renew |

| 17 - | Flange |

| 18 - | Centre bearing |

| q | Pulling off → Fig. |

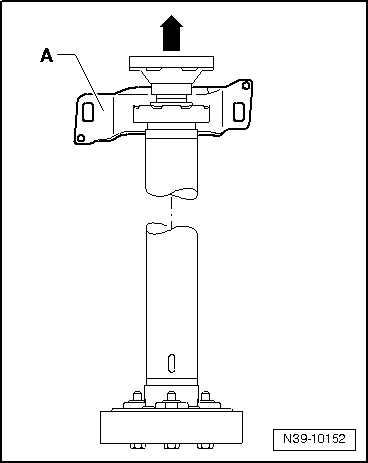

| q | Installation position → Fig. |

| q | Driving on → Fig. |

| 19 - | Bolt with washer, 25 Nm |

| q | Also secures heat shield |

| 20 - | Propshaft tube (rear) |

| q | Do not damage centring sleeve -5- and seal in centre of flange when removing and installing |

| q | Clamp in a vice to loosen and tighten bolt connections → Fig. |

| 21 - | Centring sleeve |

| 22 - | Flange bolt with twelve-point head, 60 Nm |

| 23 - | Balancing nut, 10 Nm |

| q | Not fitted on all propshafts |

| q | If the flange bolt → Item was loosened, the balancing nut and the balancing washer → Item must NOT be re-installed. |

| 24 - | Balancing washer |

| q | Only fitted on balanced final drive units |

| 25 - | Flange bolt with hexagon head, 50 Nm and turn 90° further |

| q | Always renew |

| 26 - | Flexible coupling with vibration damper |

| q | Installation position → Fig. |

| 27 - | Rear final drive |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|