| –

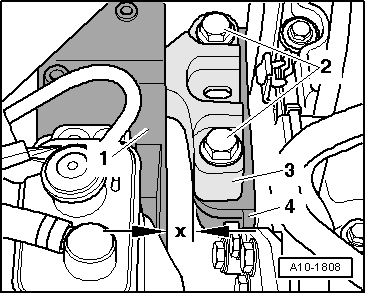

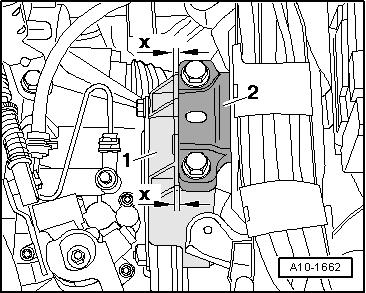

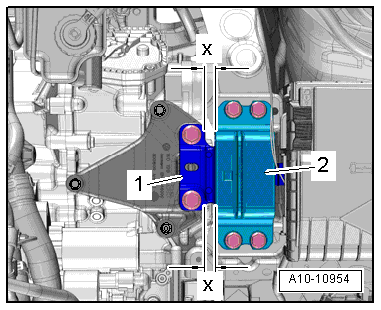

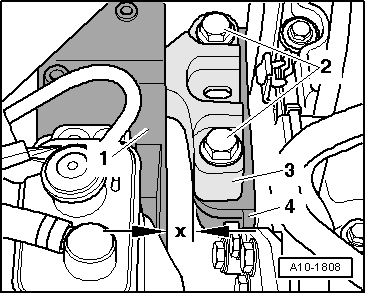

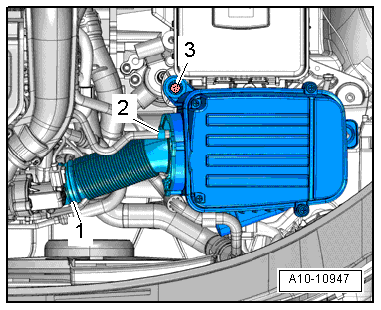

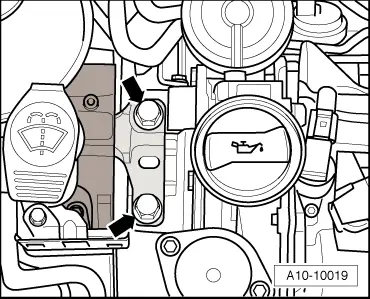

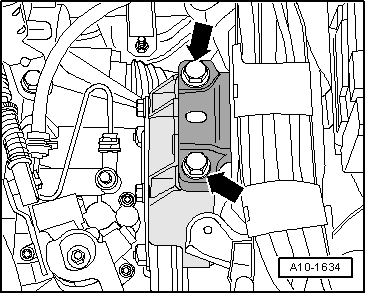

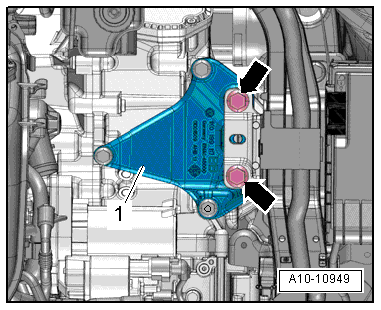

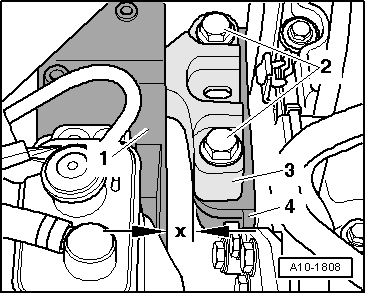

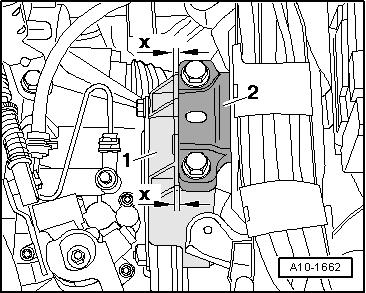

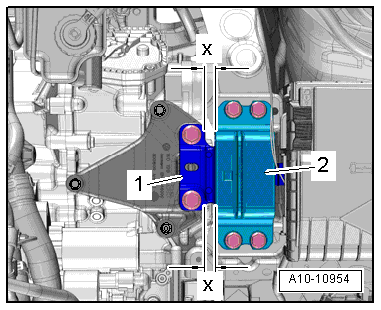

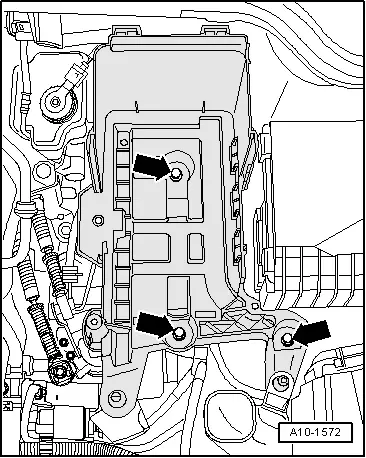

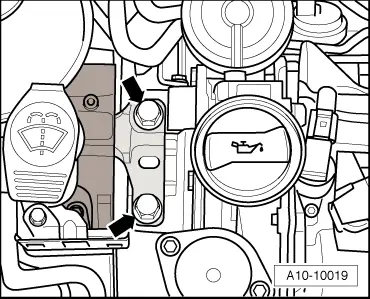

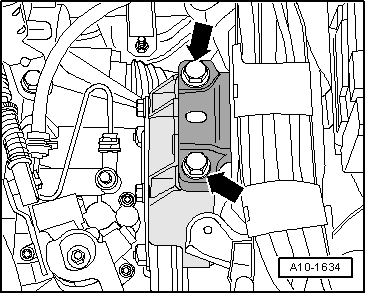

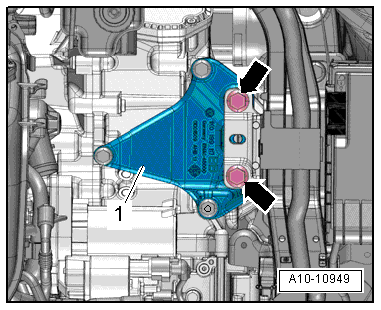

| Using an assembly lever, adjust engine/gearbox assembly between engine mounting -1- and support arm -3- for engine mounting until the specifications listed below are obtained: |

| l

| The two bolt heads -2- must be parallel with edge of support arm -3- for engine mounting. |

| l

| There must be a distance of -x- = 12 mm between engine mounting -1- and timing chain cover -4-. |

Note | Distance -x- = 12 mm can also be checked with a metal rod of suitable size, or similar. |

| –

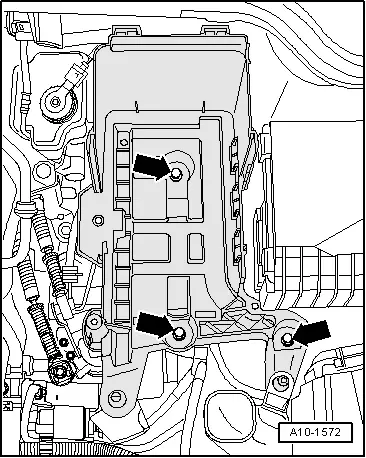

| Tighten bolts of assembly mounting at gearbox. |

|

|

|

Note

Note

Note

Note