A3 Mk2

Note

Note

|

| Component | Nm | |

| Bolts/nuts | M6 | 10 |

| M7 | 15 | |

| M8 | 22 | |

| M10 | 40 | |

| M12 | 65 | |

|

|

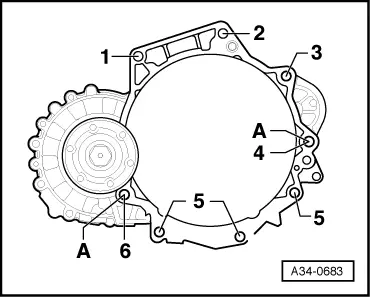

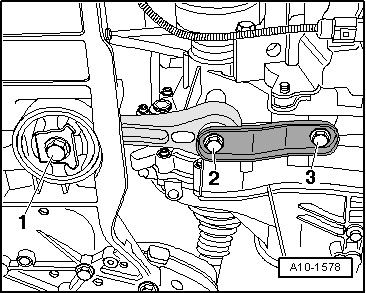

| Item | Bolt | Nm | ||||

| 1, 2 | M12x65 | 80 | ||||

| 3 1)2) | M12x150 | 80 | ||||

| 4 1)2) | M12x165 | 80 | ||||

| 5 | M10x50 | 40 | ||||

| 6 | M12x85 | 80 | ||||

| A | Dowel sleeves for centralising | |||||

| ||||||

|

|

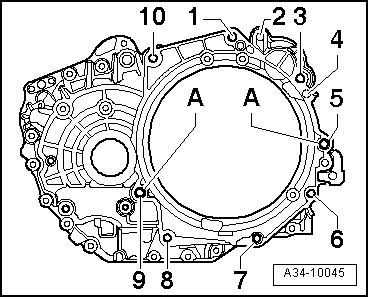

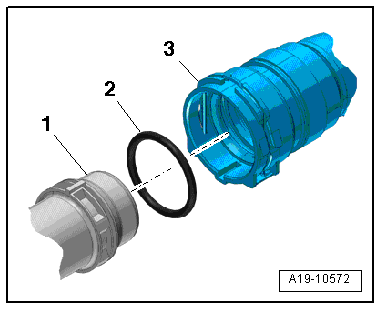

| Item | Bolt | Nm | ||

| 1, 3, 10 | M12x55 | 80 | ||

| 5, 9 | M12x70 | 80 | ||

| 6, 7, 8 | M10x50 | 40 | ||

| A | Dowel sleeves for centralising | |||

| ||||

Note

Note

|

|

|

|

|

|

|

Note

Note

|

|

|

|

Note

Note

|

|

Caution

Caution