A3 Mk2

| Checking compression |

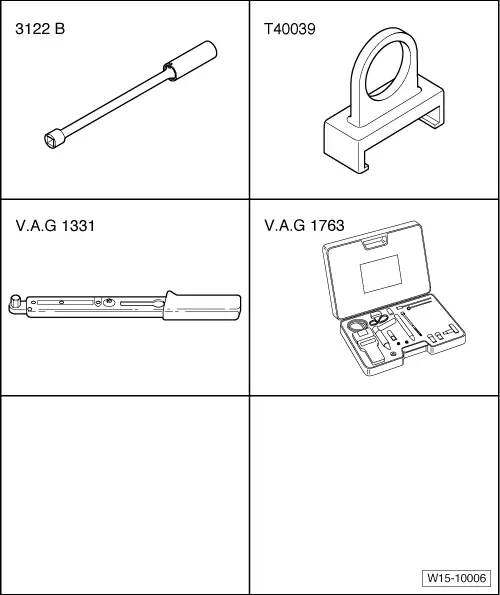

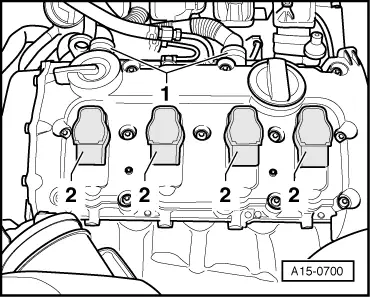

| Special tools and workshop equipment required |

| t | Spark plug socket and extension -3122 B- |

| t | Puller -T40039- |

| t | Torque wrench -V.A.G 1331- |

| t | Compression tester -V.A.G 1763- |

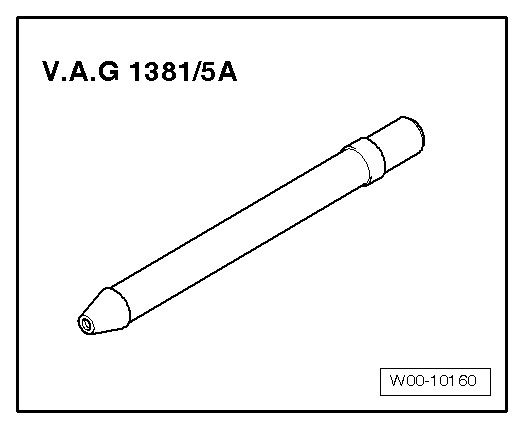

| t | Adapter -V.A.G 1381/5A- |

Note

Note

|

|

|

|

|

|

Note

Note

|

|

| Engine code letters | New pressure in bar | Wear limit bar | Permissible difference between cylinders bar |

| AXW, BLX, BLR, BVY | 11.5 | 8.0 | 3.0 (maximum) |

| BHD, BMB, BLY, BVZ | 10.5 | 7.0 | 3.0 (maximum) |

Note

Note

|

| Component | Nm |

| Spark plugs in cylinder head | 30 |