| –

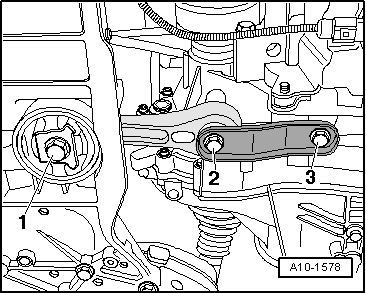

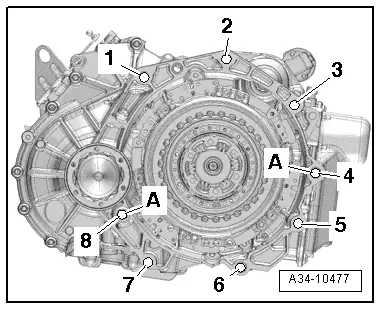

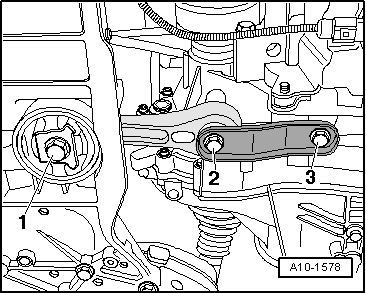

| Secure pendulum support with bolts -1 ... 3- to gearbox and subframe. |

| –

| Install front exhaust pipe with catalytic converter: vehicles with engine codes BGU, BSE, BSF, CCSA → Chapter. |

| –

| Install front exhaust pipe with catalytic converter: vehicles with engine code CMXA → Chapter. |

| –

| Align the exhaust system so it is free of stress → Chapter. |

| –

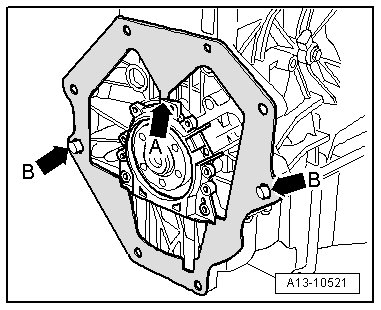

| Install slave cylinder for hydraulic clutch mechanism → Rep. gr.30. |

| –

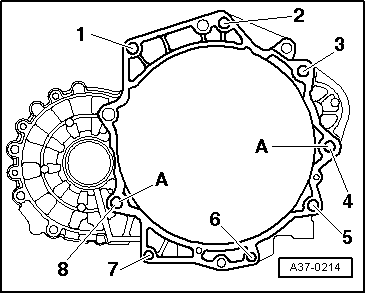

| Attach and adjust selector mechanism at manual gearbox → Rep. gr.34. |

| –

| To facilitate positioning of alternator, drive back bushes for securing bolts slightly. |

| –

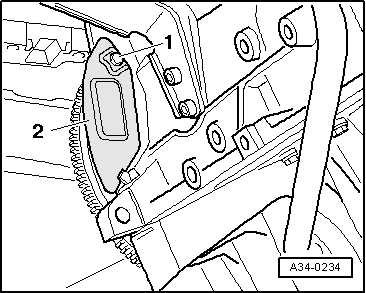

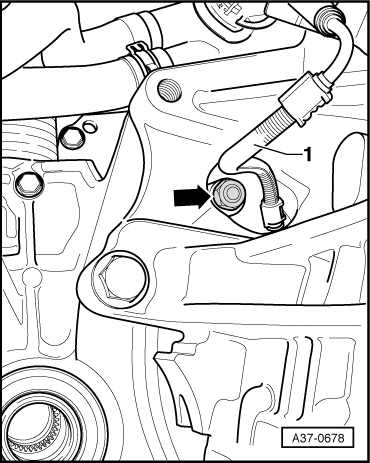

| Connect coolant hose with plug-in connector to radiator → Fig.. |

Note | t

| Drained coolant may not be used again if the cylinder head or cylinder block have been renewed. |

| t

| Contaminated or dirty coolant must not be used again. |

Caution | Never use battery charging equipment for boost starting. There is danger of damaging the vehicle's control units. |

|

|

|

|

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Caution

Caution