A3 Mk2

| Removing engine |

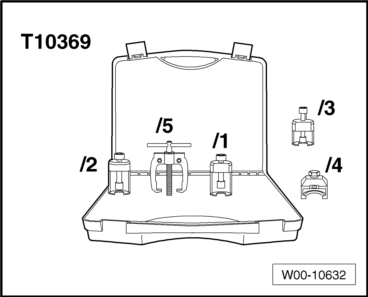

| Special tools and workshop equipment required |

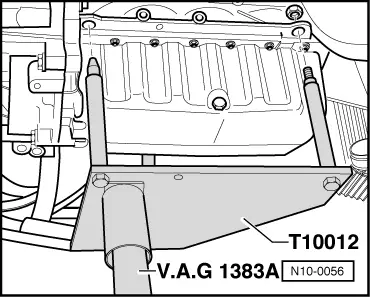

| t | Engine and gearbox jack -V.A.G 1383 A- |

| t | Hose clip pliers -V.A.G 1921- |

| t | Stepladder -VAS 5085- |

| t | Drip tray for workshop hoist -VAS 6208- |

| t | Engine bracket -T10012- |

|

|

Note

Note

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Note

Note

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Note

Note |

|

|

|

|

|

|

|

|

|

|

|

Note

Note

|

|

|

|

|

|

|

|

|

|

|

|

Note

Note

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Note

Note |

|

|

|

Note

Note

|

|

Caution

Caution WARNING

WARNING