A3 Mk2

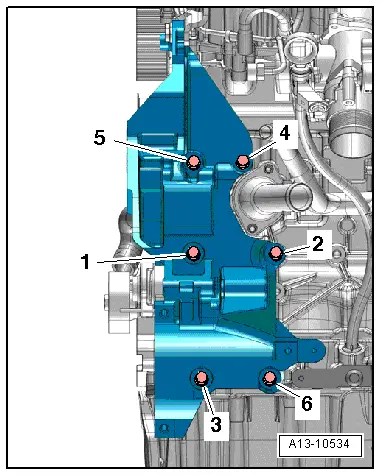

| Removing and installing bracket for ancillaries |

| Special tools and workshop equipment required |

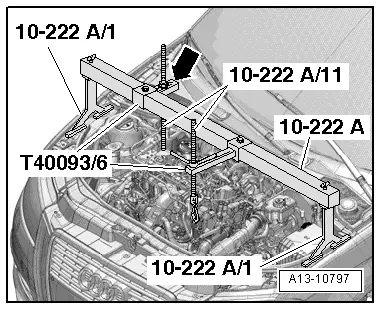

| t | Support bracket -10 - 222 A- with hexagon nut -10 - 222 A /27- |

| t | Removal lever -80 - 200- |

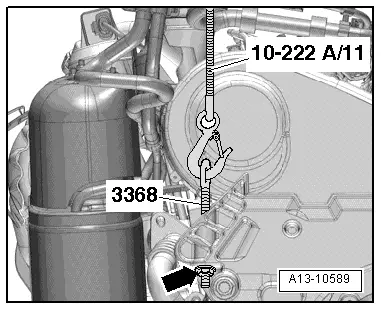

| t | Eye-head bolt -3368- |

| t | Engine support bracket (supplementary set) -T40093- |

| t | Flange nut M10 or nut M10 with washer |

|

|

|

|

|

|

|

|

|

|

|

|

Note

Note

|

|

|

|

Note

Note

|

|

WARNING

WARNING