| –

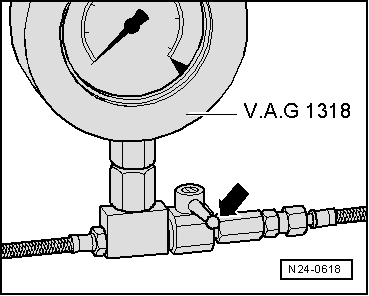

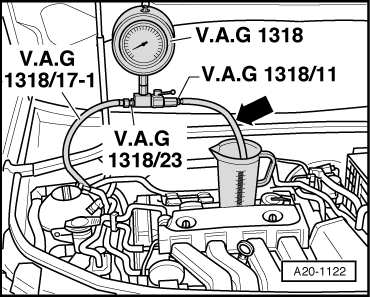

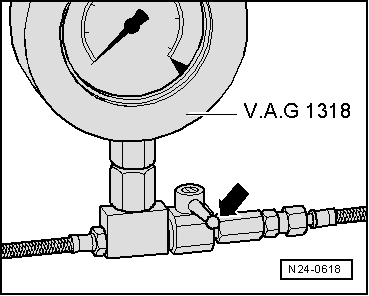

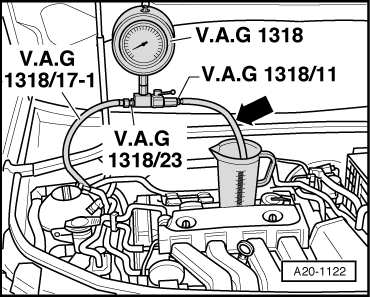

| Close cut-off tap on pressure tester -V.A.G 1318-. Lever is at right angle to direction of flow -arrow-. |

| –

| Press and hold remote control switch until pressure tester -V.A.G 1318- shows no further increase in pressure. |

| l

| Specification: approx. 6 bar (5 ... 7 bar). |

| If specification is not obtained: |

| Checking residual pressure |

| –

| Check for leaks and check residual pressure by watching drop in pressure on pressure tester -V.A.G 1318-. |

| l

| After 10 minutes pressure should still be at least 3.75 bar. |

| If the residual pressure drops below 3.75 bar: |

| t

| Check union between pressure tester -V.A.G 1318- and fuel supply line for leaks. |

| t

| Check pressure tester -V.A.G 1318- for leaks. |

| t

| Check fuel lines and their connections for leaks. |

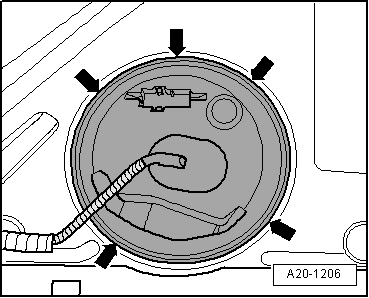

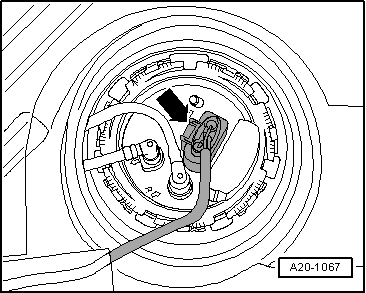

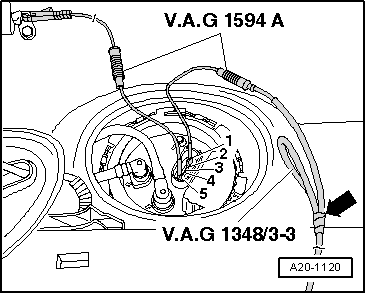

| Assembly is carried out in the reverse order; note the following: |

|

|

|

Note

Note

Note

Note

WARNING

WARNING