A3 Mk2

|

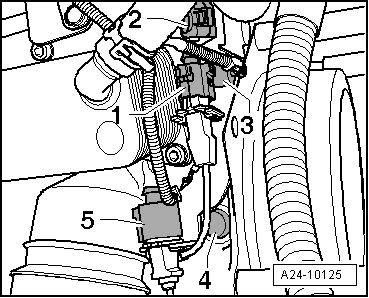

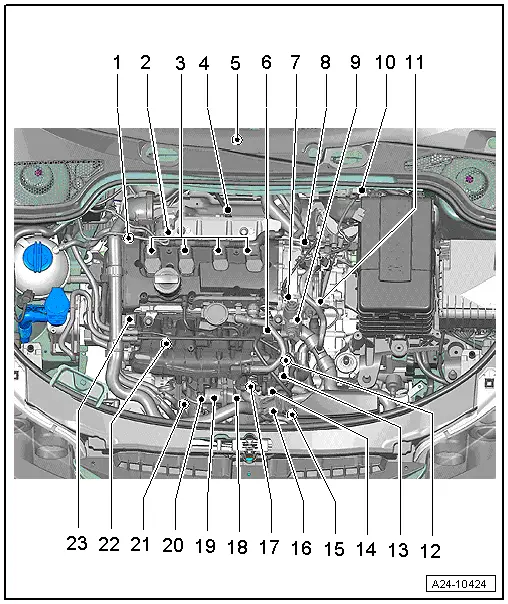

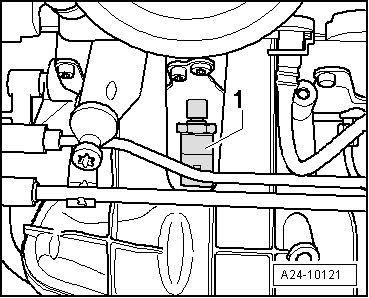

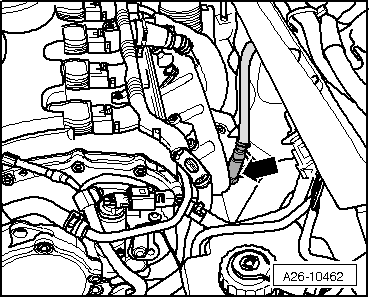

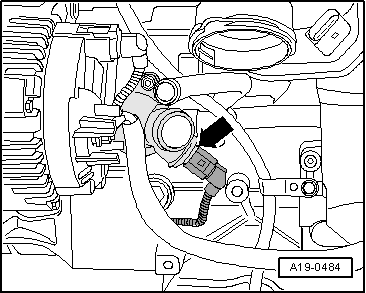

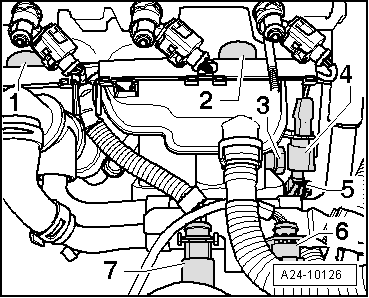

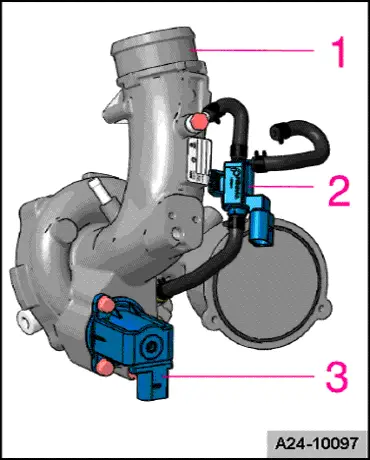

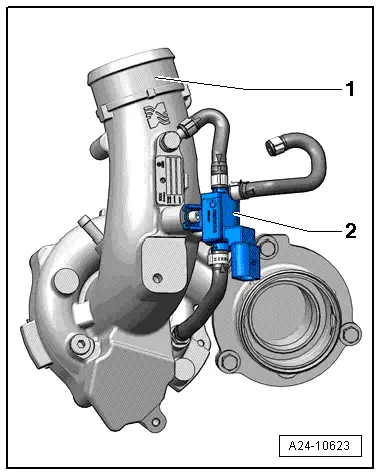

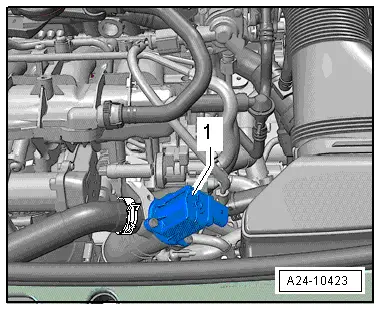

| 1 - | Solenoid valve for charge pressure control -N75- |

| q | Located directly on turbocharger → Fig. |

| 2 - | Electrical connector for air mass meter -G70- |

| q | Air mass meter -G70- in air cleaner (top section) → Fig. |

| q | Removing and installing air mass meter -G70- → Chapter |

| 3 - | Ignition coils with output stages |

| q | Removing and installing → Chapter |

| q | Ignition coil 1 with output stage -N70- |

| q | Ignition coil 2 with output stage -N127- |

| q | Ignition coil 3 with output stage -N291- |

| q | Ignition coil 4 with output stage -N292- |

| q | Puller -T40039- is required for removing ignition coils from cylinder head. |

| 4 - | Lambda probe -G39- and Lambda probe heater -Z19- |

| q | Fitting location → Fig. |

| q | Removing and installing → Chapter |

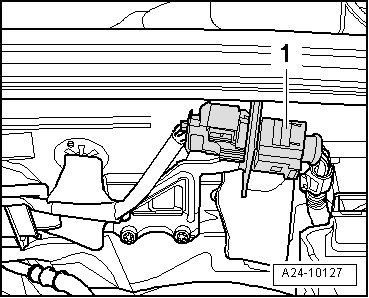

| 5 - | Engine control unit -J623- |

| q | Removing and installing → Chapter |

| 6 - | Fuel pressure sender for low pressure -G410- |

| q | 15 Nm |

| 7 - | Fuel pressure regulating valve -N276- |

| 8 - | Inlet camshaft control valve 1 -N205- |

| q | Removing and installing → Rep. Gr.15 |

| 9 - | Single-plunger high-pressure pump |

| q | Removing and installing → Chapter |

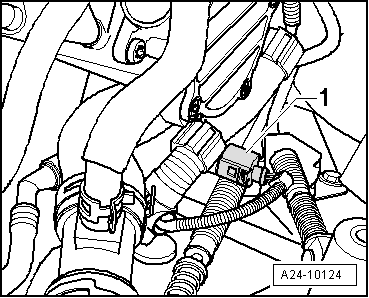

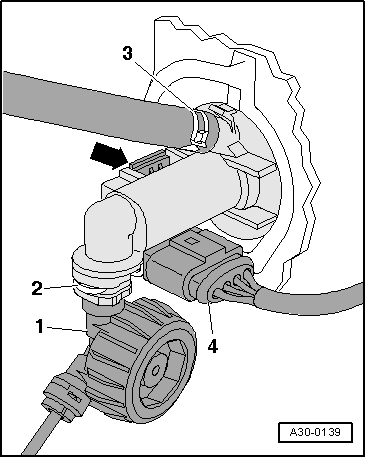

| 10 - | 6-pin connector |

| q | For Lambda probe -G39- and Lambda probe heater -Z19- (black) → Fig. |

| 11 - | Coolant temperature sender -G62- |

| q | Fitting location → Fig. |

| 12 - | Components |

| q | Engine speed sender -G28- |

| q | Checking oil pressure switch -F1- → Rep. Gr.17 |

| q | 3-pin connector for knock sensor 1 -G61- |

| q | 3-pin connector for knock sensor 2 -G66- |

| q | Fitting location → Fig. |

| 13 - | Intake manifold flap motor -V157- with intake manifold flap potentiometer -G336- |

| q | After the fuel rail has been removed or renewed, intake manifold flap potentiometer -G336- must be adapted to the engine control unit -J623-, see vehicle diagnostic and service information system -VAS 5052-, “Guided Functions” |

| q | Removing and installing → Chapter |

| 14 - | Activated charcoal filter solenoid valve 1 -N80- |

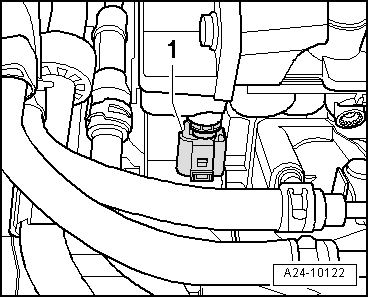

| 15 - | Charge air pressure sender -G31- |

| q | Fitting location → Fig. |

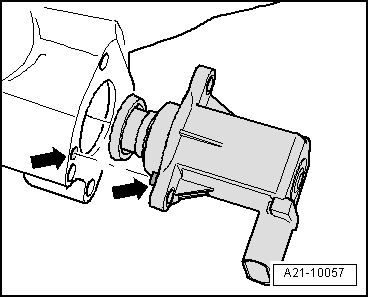

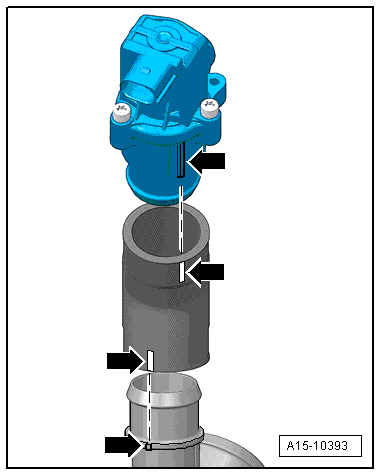

| 16 - | Turbocharger air recirculation valve -N249- |

| q | Fitting location → Fig. |

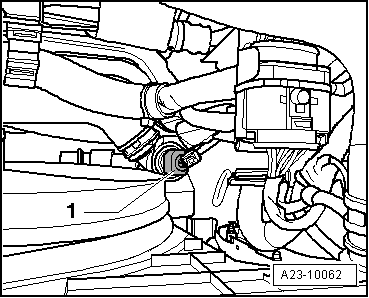

| 17 - | Connector |

| q | For Hall sender -G40- and fuel pressure sender -G247- |

| q | Fitting location → Fig. |

| 18 - | 8-pin connector for injectors |

| q | Fitting location → Fig. |

| 19 - | Throttle valve module -J338-, throttle valve drive for electric throttle -G186- |

| q | Throttle valve drive angle sender 1 for electric throttle -G187- and throttle valve drive angle sender 2 for electric throttle -G188- |

| q | After the throttle valve module -J338- has been renewed, it must be adapted to the engine control unit -J623-, see vehicle diagnostic and service information system -VAS 5052-“Guided Functions” |

| 20 - | Intake air temperature sender -G42- |

| q | 11 Nm |

| 21 - | Radiator outlet coolant temperature sender -G83- |

| q | Fitting location → Fig. |

| 22 - | Fuel pressure sender -G247- |

| q | 22 Nm |

| q | Fitting location → Fig. |

| q | Removing and installing → Chapter |

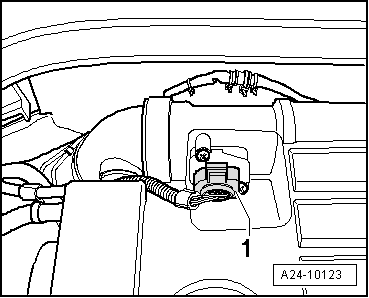

| 23 - | Hall sender -G40- (camshaft position sensor) |

| q | Electrical connector → Fig. |

| A - | Diagnostic connector |

| q | In driver's knee restraint |

| B - | Knock sensor 1 -G61- |

| q | For cylinders 1 and 2 |

| q | 20 Nm |

| q | Fitting location → Fig. |

| q | Removing and installing → Chapter |

| C - | Knock sensor 2 -G66- |

| q | For cylinders 3 and 4 |

| q | 20 Nm |

| q | Fitting location → Fig. |

| q | Removing and installing → Chapter |

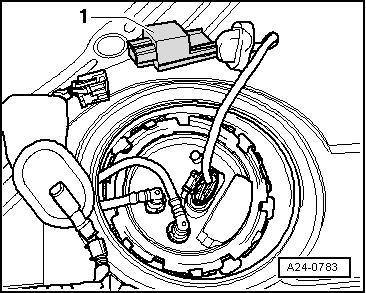

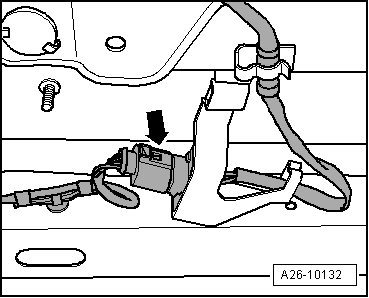

| D - | Fuel pump control unit -J538- |

| q | Fitting location → Fig. |

| q | Adaption must be performed after renewing fuel pump control unit -J538-; refer to → Rep. Gr.20. |

| E - | Lambda probe after catalytic converter -G130- and Lambda probe heater 1 after catalytic converter -Z29- |

| q | Fitting location → Fig. |

| q | Removing and installing → Chapter |

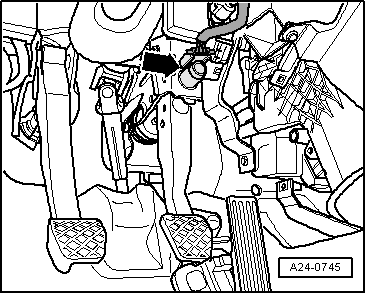

| F - | Brake light switch - F- and brake pedal switch -F63- |

| q | Fitting location → Fig. |

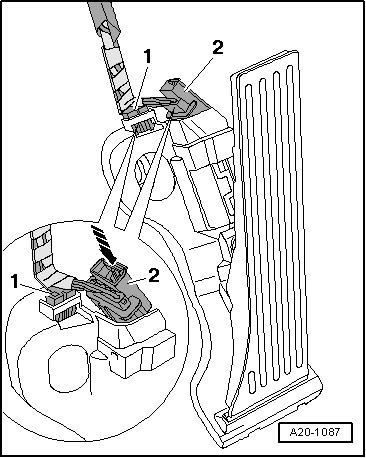

| G - | Accelerator position sender -G79- and accelerator position sender 2 -G185- |

| q | On accelerator pedal (both senders are accommodated in one housing) |

| q | → Fig. |

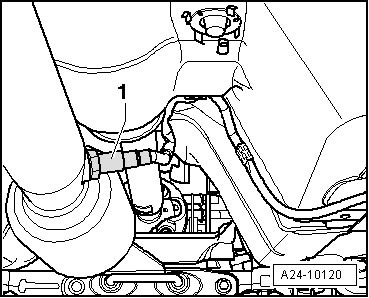

| H - | Clutch position sender -G476- |

| q | Only fitted on vehicles with manual gearbox |

| q | Fitting location → Fig. |

| q | Removing and installing, see Power transmission, clutch → Rep. Gr.30 |

| I - | Relay and fuse holder in electronics box |

| q | Assignment, refer to → Current flow diagrams, Electrical fault finding and Fitting locations |

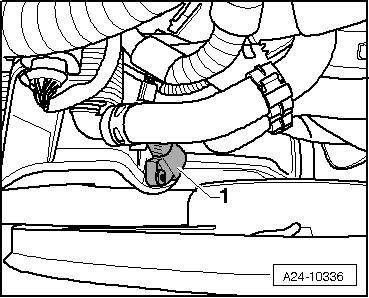

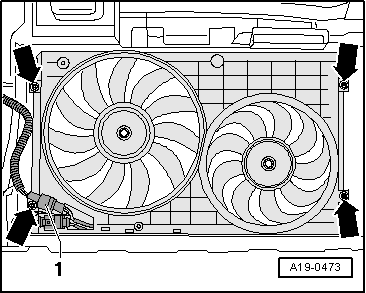

| J - | Radiator fan control unit -J293- |

| q | Fitted on left-side radiator fan (in direction of travel) |

| q | Fitting location → Fig. |

| K - | Injectors |

| q | In fuel rail |

| q | Removing and installing → Chapter |

| q | Injector, cylinder 1 -N30- |

| q | Injector, cylinder 2 -N31- |

| q | Injector, cylinder 3 -N32- |

| q | Injector, cylinder 4 -N33- |

| The fuel injectors are high-pressure injectors. They inject fuel at high pressure (maximum approx. 120 bar) directly into the cylinder. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Note

Note

|

|

|

|

|

|

|

|

|

|

|

|