| Continued for all vehicles: |

| –

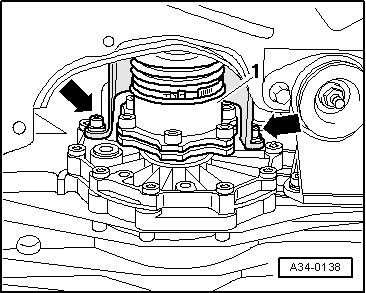

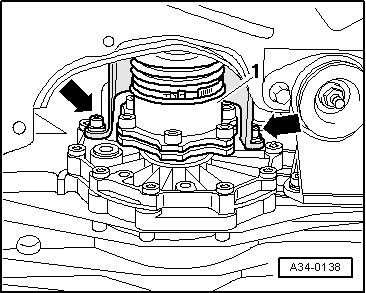

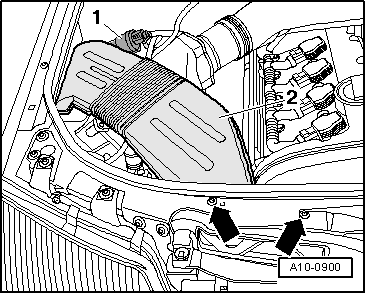

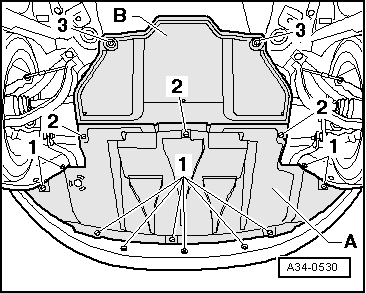

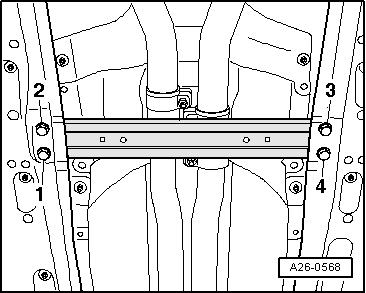

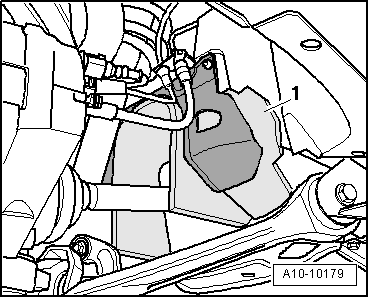

| If fitted, unbolt heat shield for right-side drive shaft -arrows-. |

| –

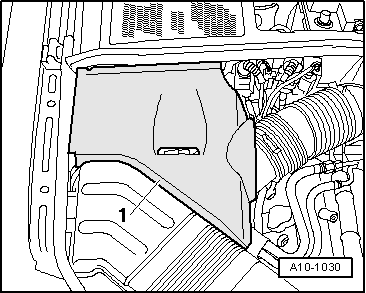

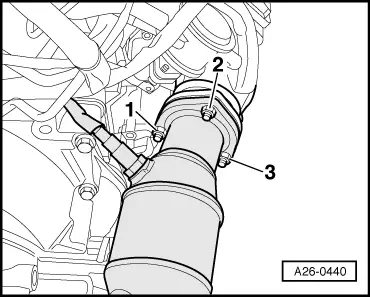

| Remove drive shaft -1- (right-side) from gearbox flange shaft and tie up to on side as high as possible. |

Note | Make sure you do not damage surface coating on drive shaft. |

| –

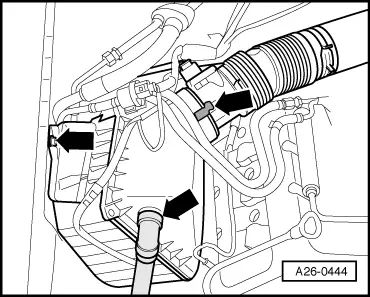

| Place drip tray beneath gearbox. |

| –

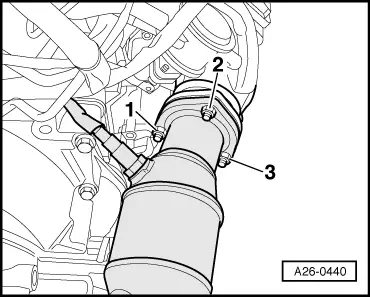

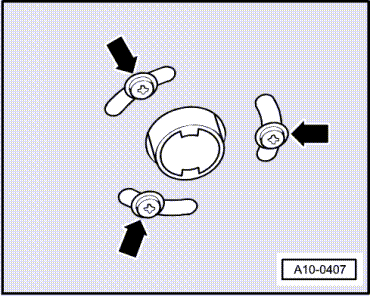

| Remove bolt securing flange shaft. To do so, screw two bolts into flange and counterhold flange shaft with suitable lever. |

| Installation is carried out in reverse sequence; note the following: |

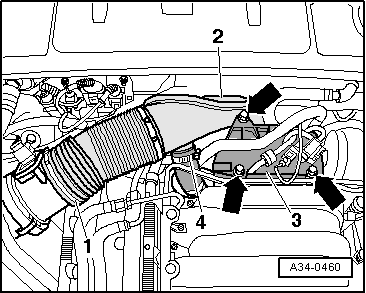

| Vehicles with V6 petrol engine: |

| –

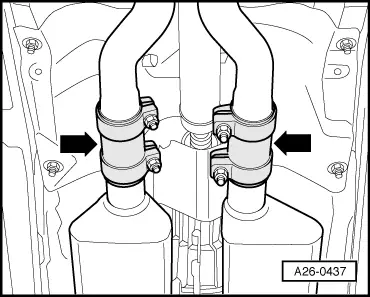

| Install front exhaust pipe and perform stress-free alignment → Rep. Gr.26. |

| Continued for all vehicles: |

| –

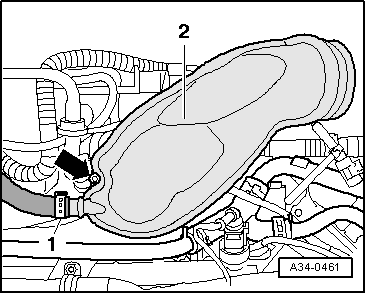

| Install heat shield for drive shaft. |

| –

| Fill manual gearbox with gear oil and check oil level → Chapter. |

|

|

|

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note