A4 Cabriolet Mk2

|

| 1 - | Flywheel/dual mass flywheel |

| q | Ensure that dowel pins fit tightly |

| q | Contact surface for clutch lining must be free of grooves, oil and grease |

| q | Removing and installing → Rep. gr.13 |

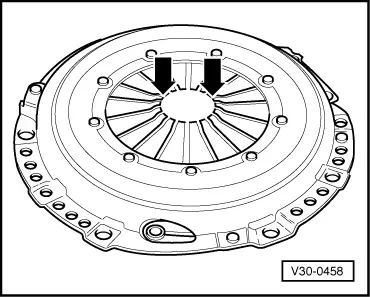

| q | Do not use a pneumatic wrench or impact wrench to remove dual-mass flywheel → Fig. |

| 2 - | Bolt |

| q | For flywheel |

| q | Tightening torque for bolt length 22.5 mm: 60 Nm + 90° further |

| q | Tightening torque for bolt length 43 mm: 60 Nm + 180° further |

| q | Renewing → Rep. gr.13 |

| 3 - | Clutch plate |

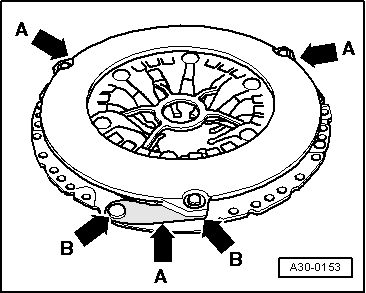

| q | The marking „Getriebeseite“ (gearbox side), if provided, faces towards pressure plate/gearbox |

| q | Coil springs (damper assembly) point towards pressure plate and gearbox |

| q | Centralising → Anchor |

| q | Lightly grease splines → Anchor |

| q | For diameter of clutch plate, refer to → Electronic parts catalogue |

| 4 - | Pressure plate |

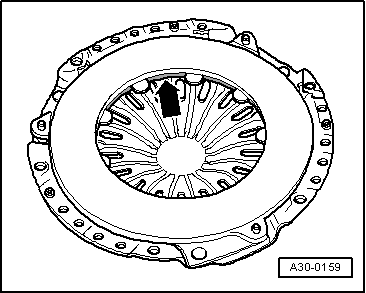

| q | Removing and installing → Chapter |

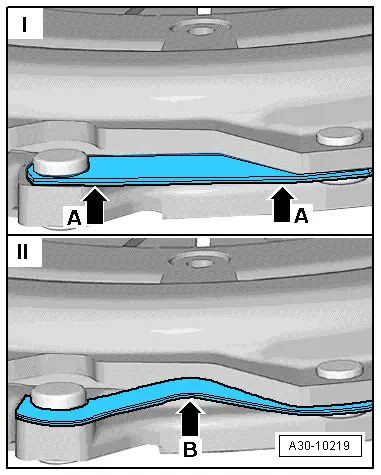

| q | Checking ends of diaphragm spring → Fig. |

| q | Checking springs and riveting → Fig. |

| q | Checking wire ring → Fig. |

| q | Contact surface for clutch lining must be free of grooves, oil and grease |

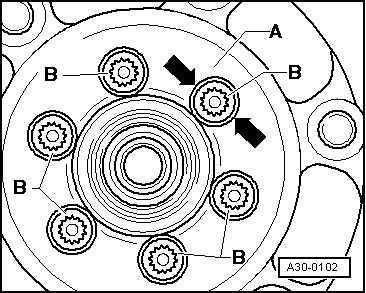

| 5 - | Bolt |

| q | 22 Nm |

| q | Loosen and tighten gradually in several stages and in diagonal sequence |

| 6 - | Needle bearing |

| q | Removing and installing → Rep. gr.13 |

Note

Note

|

|

|

|

|

|

|

|

Caution

Caution