| t

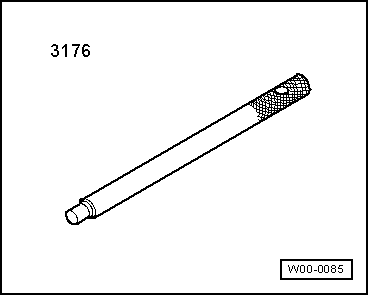

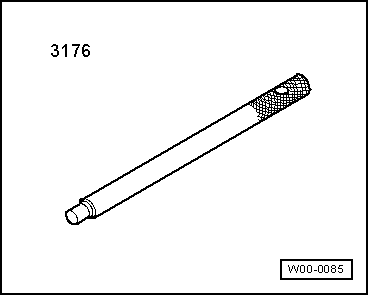

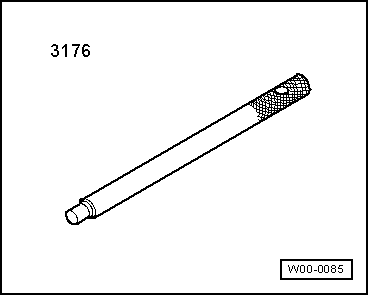

| Centring mandrel -3176- |

| t

| Grease for clutch plate splines -G 000 100- |

| –

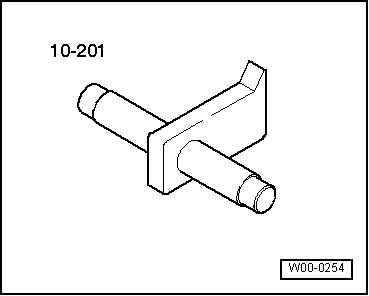

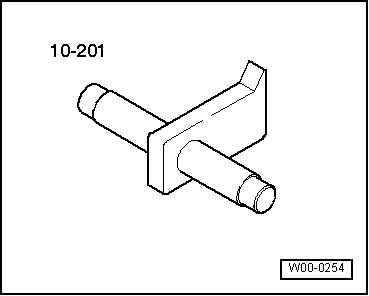

| Apply counterhold tool -10-201- or -3067- in order to loosen bolts. |

| To prevent the pressure plate from becoming distorted during removal (causes clutch grab when driving off), always adhere to the following procedure when unbolting the pressure plate: |

| –

| Loosen all bolts consecutively in clockwise direction and in steps of 90° (1/4 turn) until the pressure plate is released. |

|

|

|