| –

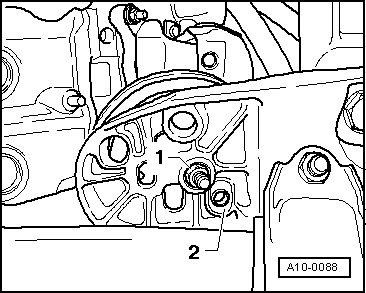

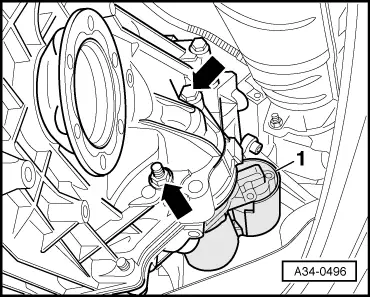

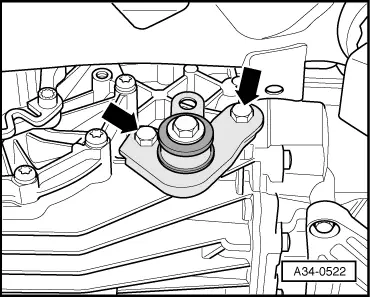

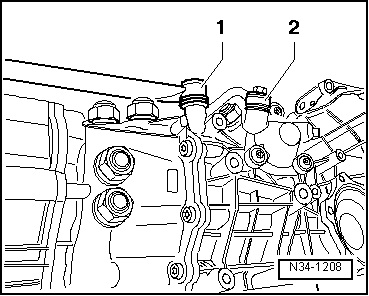

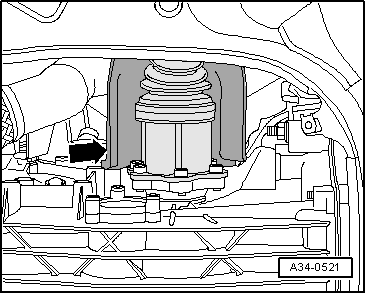

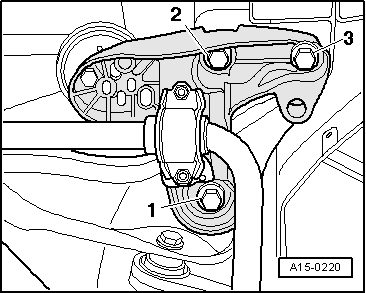

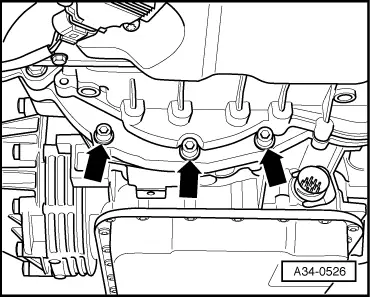

| Tighten nuts -1- for engine mountings. |

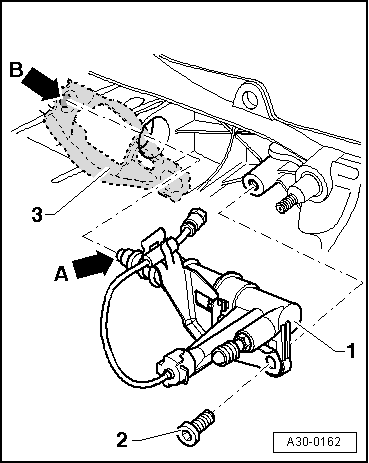

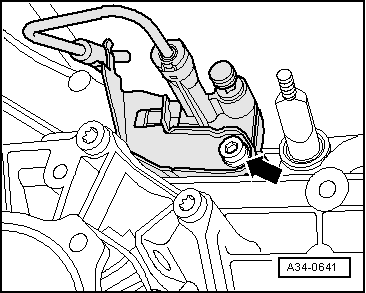

| The remaining installation steps are carried out in the reverse sequence; note the following points: |

| –

| Check selector mechanism setting and adjust if necessary → Chapter. |

Note | t

| Tightening torques apply only to lightly greased, oiled, phosphated or black-finished nuts and bolts. |

| t

| Additional lubricant such as engine or gearbox oil may be used, but do not use graphite lubricant. |

| t

| Do not use parts which have been degreased. |

| t

| Tolerance for tightening torques ±15%. |

|

|

|

Note

Note Note

Note

Note

Note

Note

Note

Note

Note

Caution

Caution WARNING

WARNING