A4 Cabriolet Mk2

| Removing gearbox - vehicles with 2.5 ltr. TDI engine |

| Special tools and workshop equipment required |

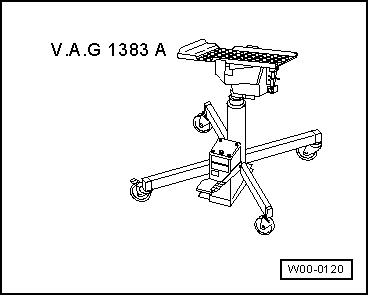

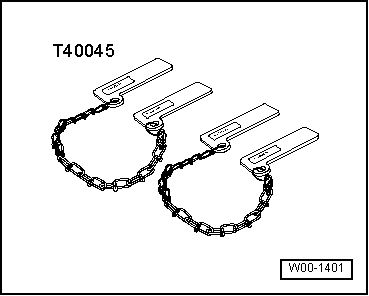

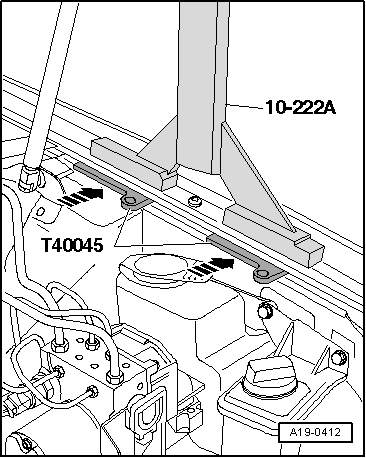

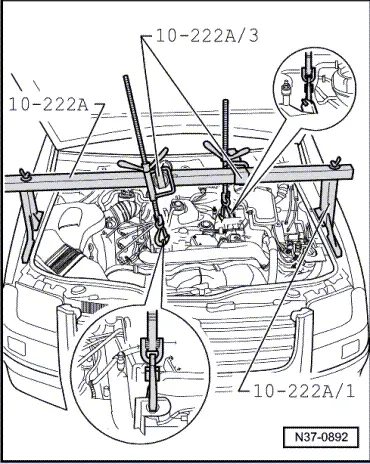

| t | Support bracket -10-222 A- |

| t | Rack -10-222 A /1- |

| t | Adapter -10-222 A /3- |

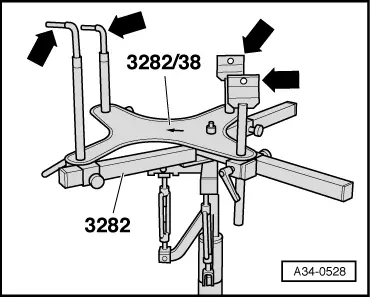

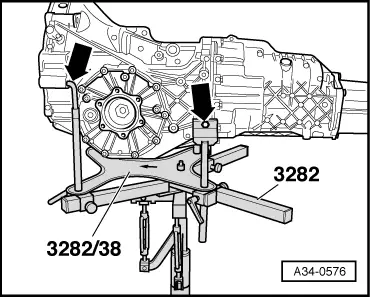

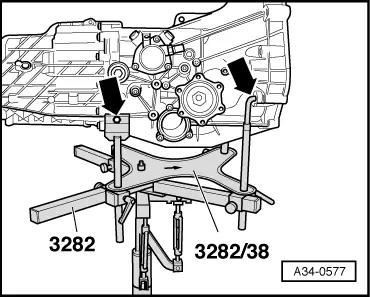

| t | Gearbox support -3282- |

| t | Adjustment plate -3282/38- |

| t | Mounts -3282/49- (2x) |

| t | Mounts -3282/52- (2x) |

|

|

|

|

Note

Note

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Note

Note

|

|

|

|

|

|

Note

Note

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Note

Note

|

|

|

|

Note

Note

|

|

|

|

|

|

|

|

|

|

Note

Note

|

|

|

|

|

|

|

|

Note

Note

Note

Note

|

|

|

|

Caution

Caution