| –

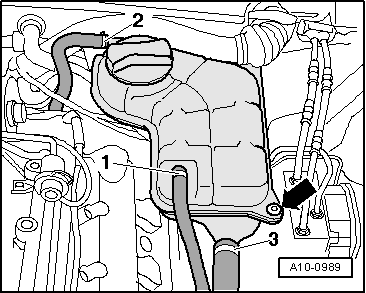

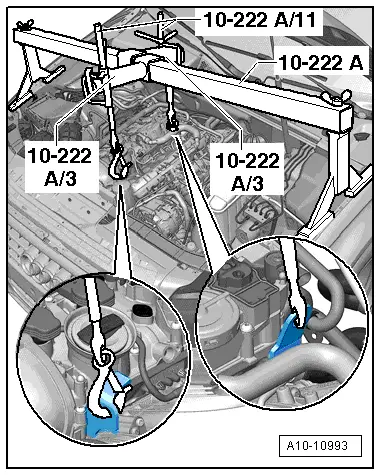

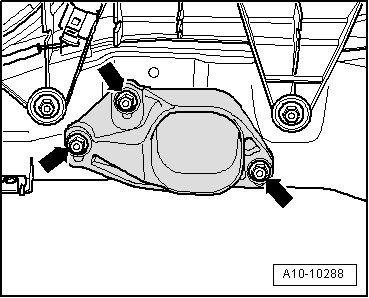

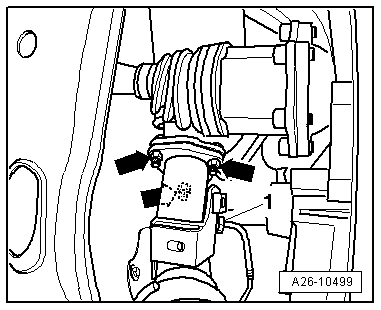

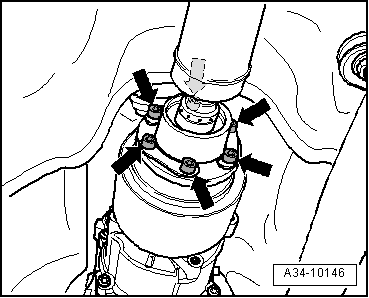

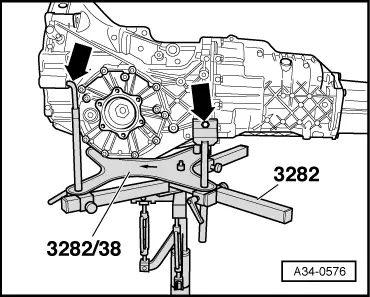

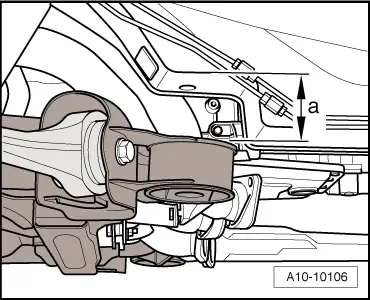

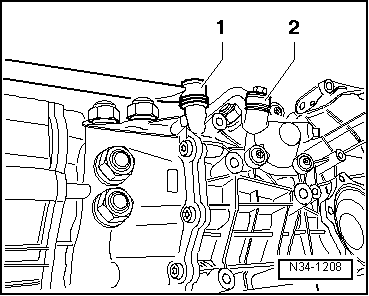

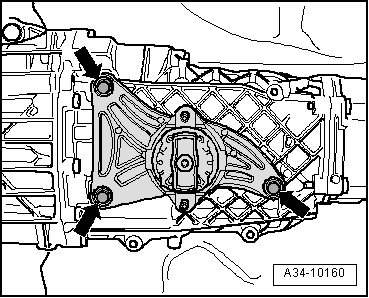

| Press gearbox off dowel sleeves and lower carefully with engine and gearbox jack -V.A.G 1383 A- just far enough to gain access to the clutch slave cylinder. |

Note | When lowering gearbox, ensure hydraulic line to clutch slave cylinder is not damaged. |

| –

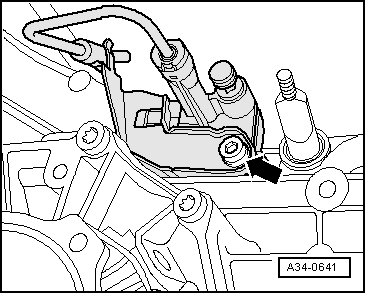

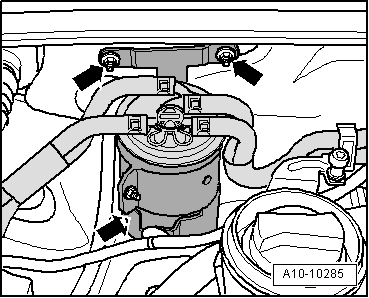

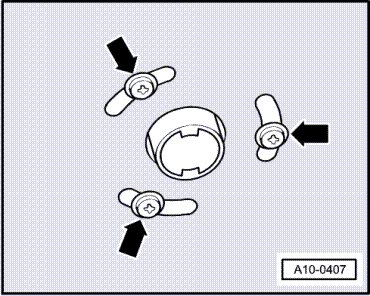

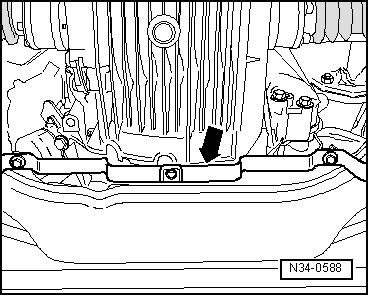

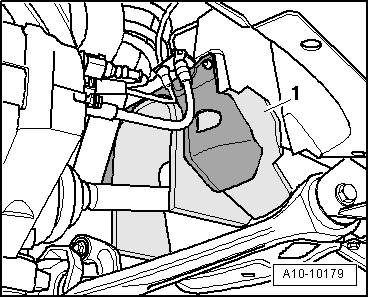

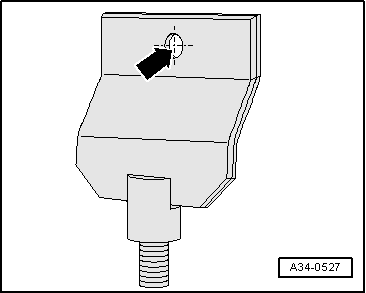

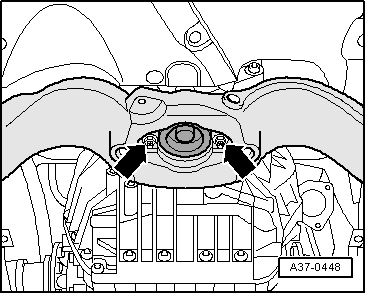

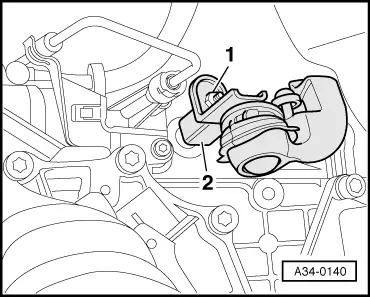

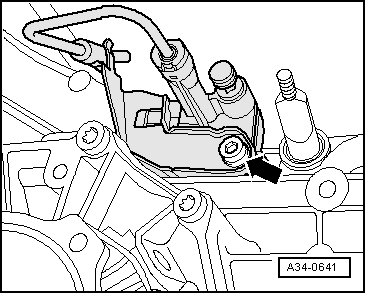

| Detach clutch slave cylinder from gearbox -arrow- and secure with wire; do not open pipe/hose system. |

Caution | Do not depress clutch pedal after removing slave cylinder. The slave cylinder would then be destroyed once pedal force exceeds approx. 300 N. |

|

| –

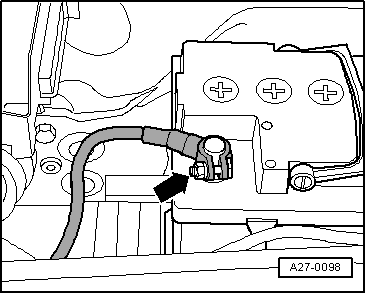

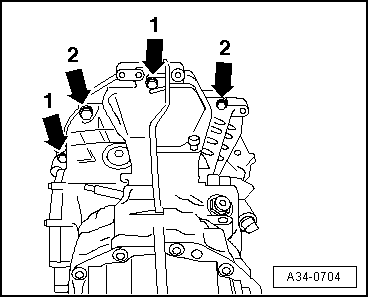

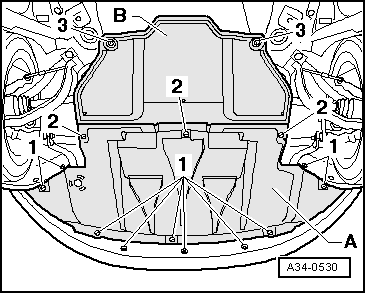

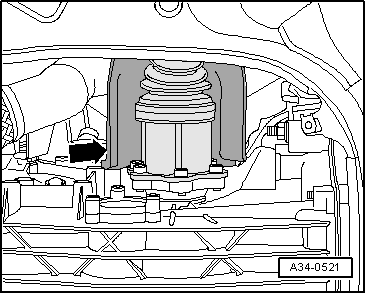

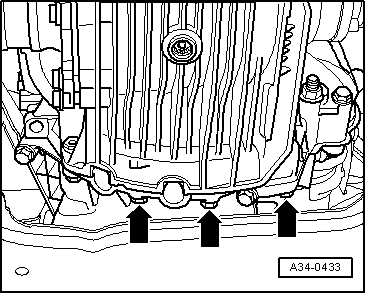

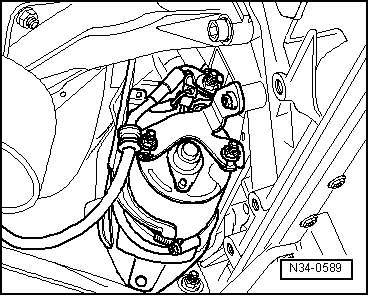

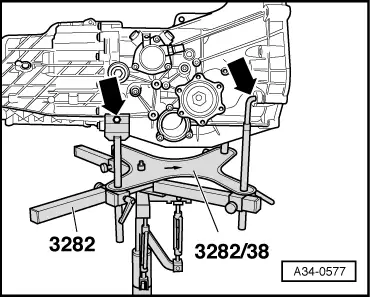

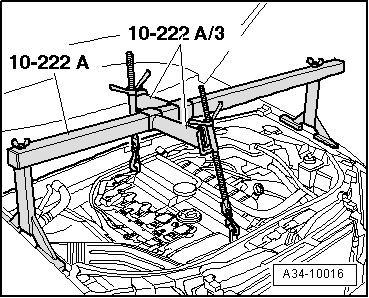

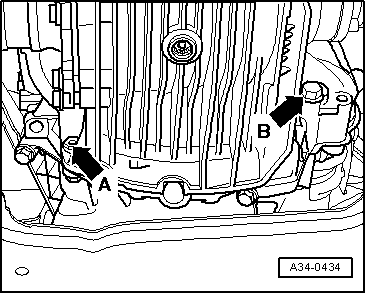

| If fitted, move clear electrical wiring at top of gearbox. |

| –

| Lower gearbox completely. |

Note | When lowering gearbox, make sure there is sufficient clearance from drive shafts. |

|

|

|

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note Note

Note

Caution

Caution