A4 Cabriolet Mk2

| Removing and installing camshaft adjuster |

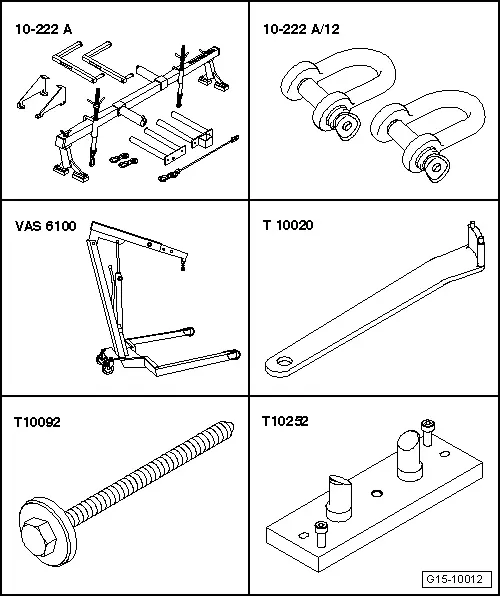

| Special tools and workshop equipment required |

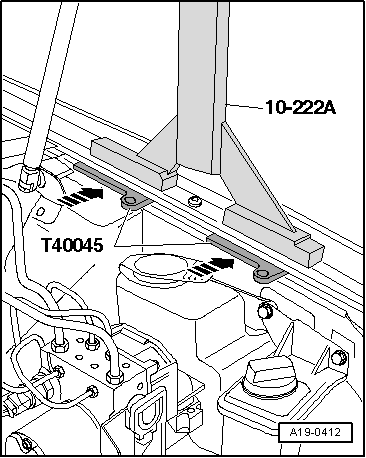

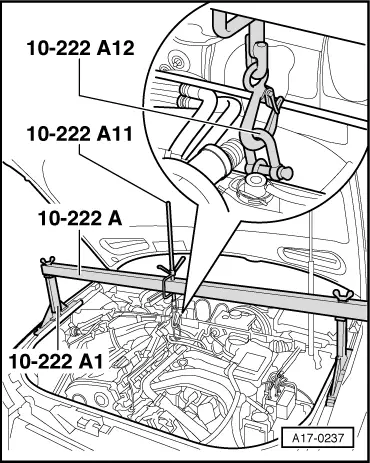

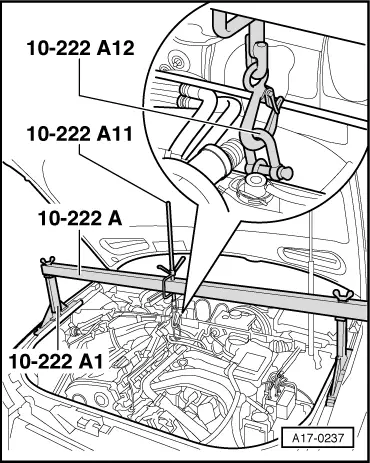

| t | Support bracket -10-222 A- |

| t | Shackle -10 -222 A /12- |

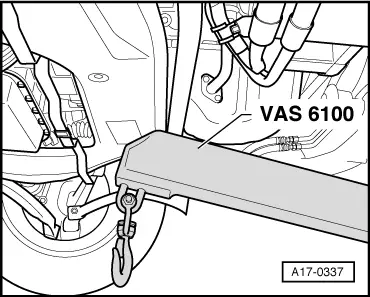

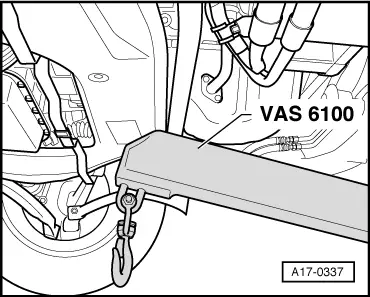

| t | Workshop hoist -VAS 6100- or -V.A.G 1202 A- |

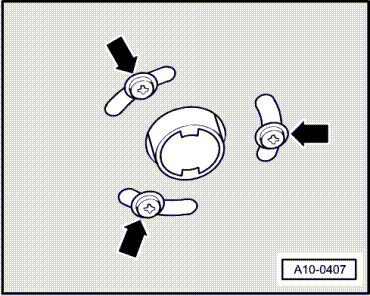

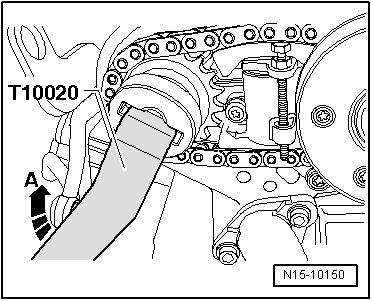

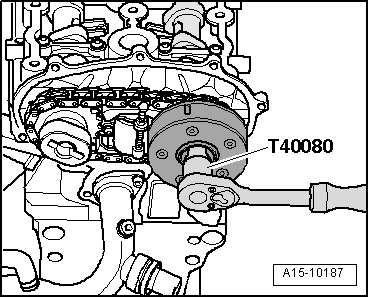

| t | Pin wrench -T10020- |

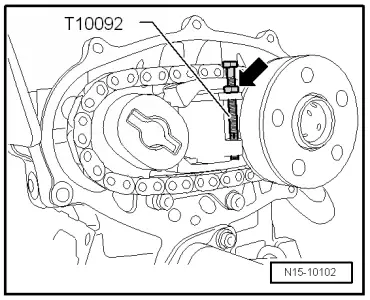

| t | Tensioning bolt -T10092- |

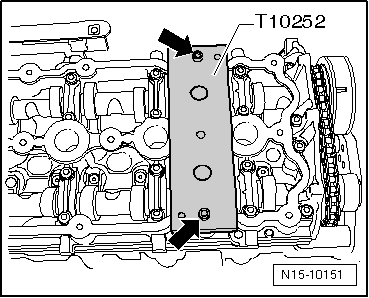

| t | Camshaft clamp -T10252- |

|

|

|

|

Note

Note

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Note

Note |

|

|

|

|

|

|

|

Note

Note

|

|

Note

Note

|

|

|

|

Note

Note

|

|

|

|

|

|

|

|

Note

Note

|

|

|

|

Note

Note

|

|

|

|

Note

Note

|

|

|

|

| Component | Nm | ||

| Camshaft adjuster to camshaft | 100 | ||

| Chain tensioner to cylinder head | 10 1) | ||

| Camshaft adjuster cover to cylinder head | 10 1) | ||

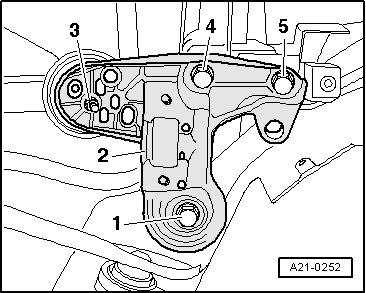

| Console for engine mounting to longitudinal member | 75 | ||

| Engine mounting to console for engine mounting | 23 | ||

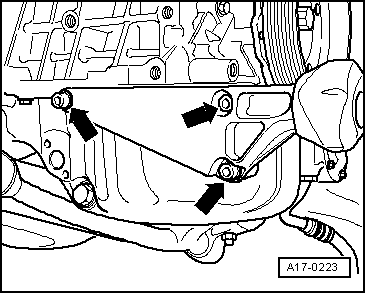

| Torque reaction support to sump | 23 | ||

| |||

WARNING

WARNING Caution

Caution