| t

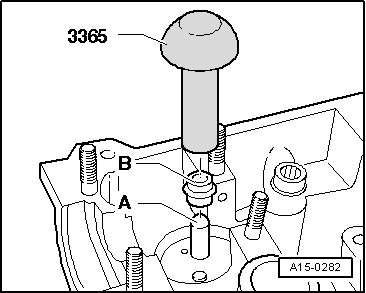

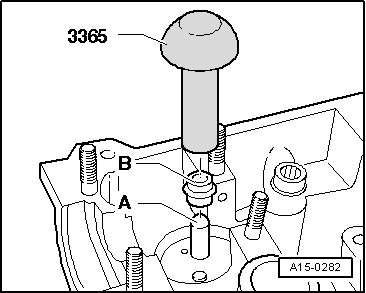

| A plastic sleeve -A- is included with the new valve stem oil seals. |

| t

| Sealing sleeves are fitted on the valve guides sleeves on certain engine versions. |

| t

| If fitted, these sealing sleeves must not be removed → Item. Also, do not remove sealant in sleeves. |

| –

| Fit plastic sleeve -A- onto the valve stem to prevent damage to the new valve stem oil seal -B-. |

| –

| Lightly lubricate sealing lip of valve stem oil seal. |

| –

| Slip valve stem oil seal over plastic sleeve. |

| –

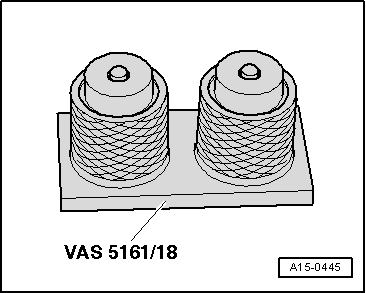

| Carefully press valve stem oil seal onto valve guide using valve stem seal fitting tool -3365-. |

| –

| Remove the plastic sleeve. |

|

|

|

Note

Note

Note

Note