| –

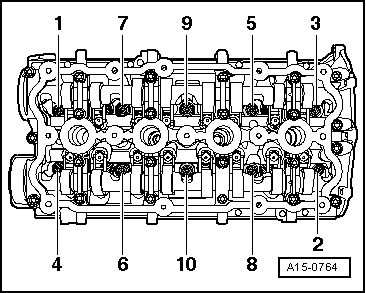

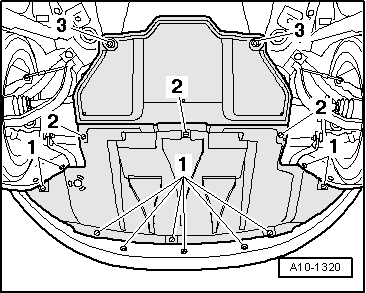

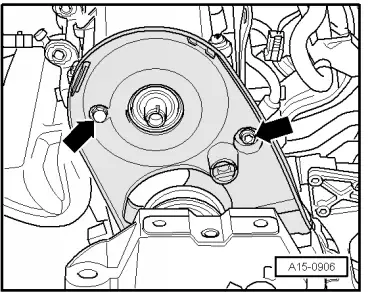

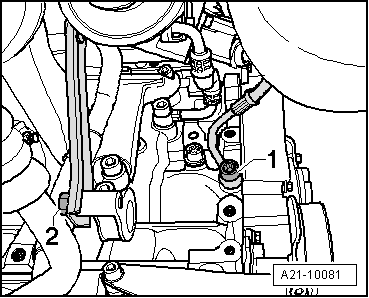

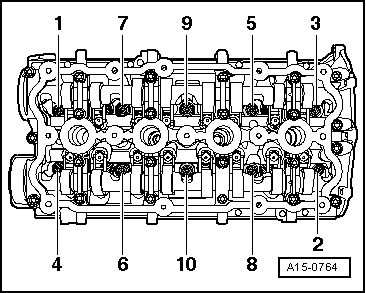

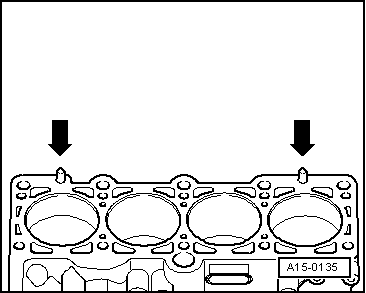

| Loosen cylinder head bolts, keeping to sequence shown. |

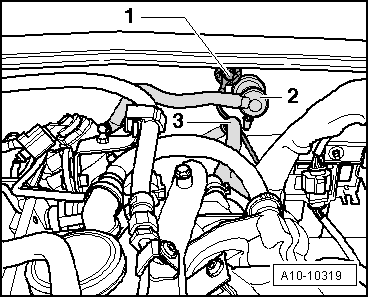

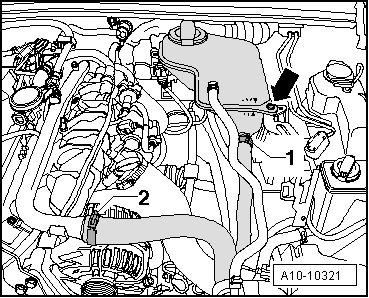

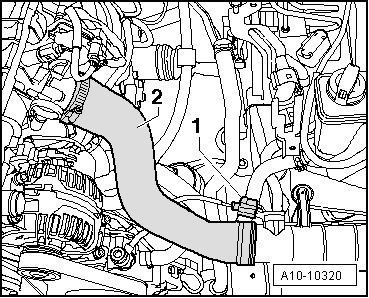

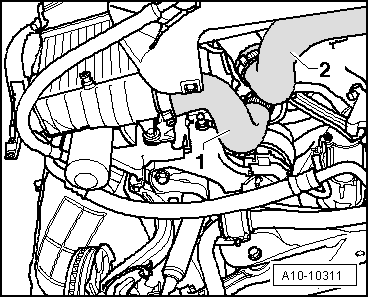

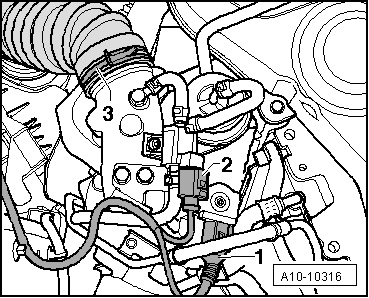

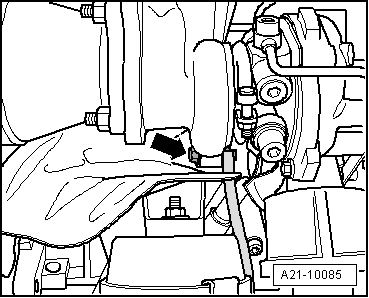

Note | Check that all hoses, pipes and wiring connections between engine, gearbox and body have been detached. |

Note | t

| Renew the cylinder head bolts. |

| t

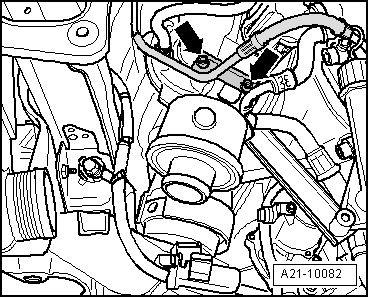

| On assembly, renew oil seals and gaskets as well as self-locking nuts and bolts that are tightened by turning through to a specified angle. |

| t

| Secure all hose connections with the correct type of hose clips (same as original equipment) → Parts catalogue. |

| t

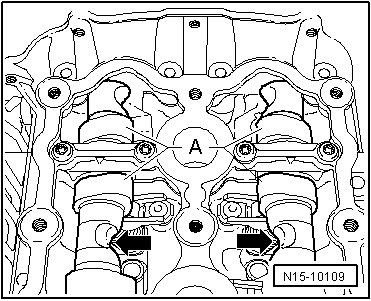

| If repairing, carefully remove any remaining gasket material from the cylinder head and cylinder block. Ensure that no long scores or scratches are made on the surfaces. |

| t

| Carefully remove any remaining emery and abrasive material. |

| t

| Do not remove new cylinder head gasket from packaging until it is ready to be fitted. |

| t

| Handle gasket very carefully. Damage to the silicone coating or the indented area will lead to leaks. |

| t

| No oil or coolant must be allowed to remain in the blind holes for the cylinder head bolts in the cylinder block. |

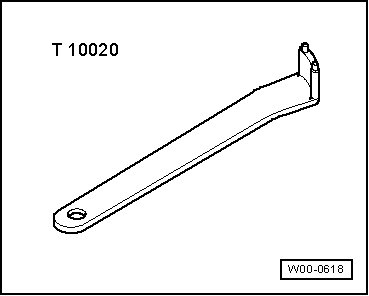

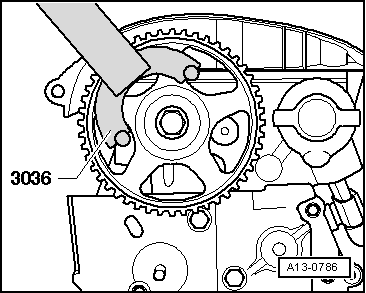

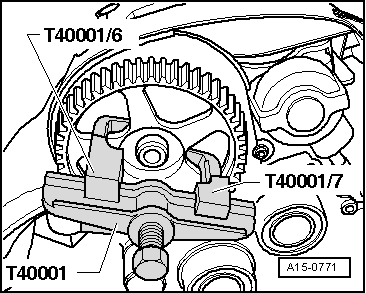

WARNING | The engine must only be turned at the crankshaft, in the direction of normal engine rotation (clockwise). |

|

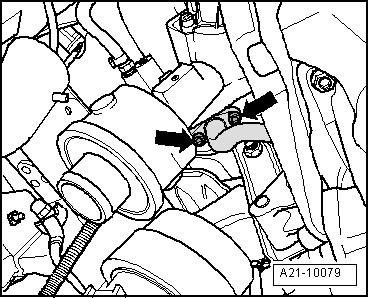

Note | Apply spanner to central bolt of crankshaft for turning engine. |

|

|

|

Note

Note

Note

Note Note

Note Note

Note

Note

Note Note

Note

WARNING

WARNING