| –

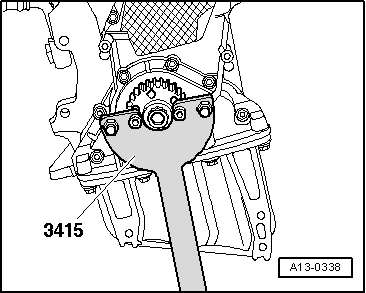

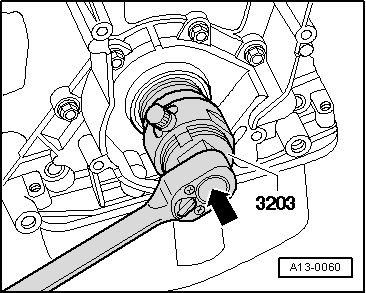

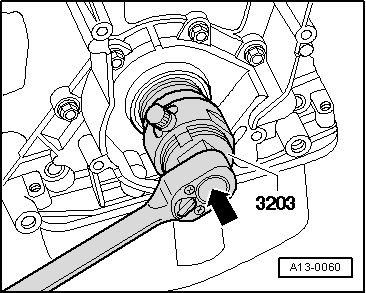

| Unscrew inner section of oil seal extractor -3203- 8 turns out of outer section and lock with knurled screw. |

| –

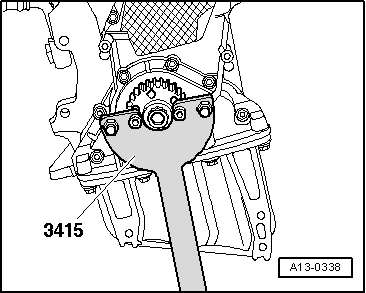

| Lubricate threaded head of oil seal extractor, place it in position and, exerting firm pressure -arrow-, screw it into oil seal as far as possible. |

| –

| Loosen knurled screw and turn inner part against crankshaft until the oil seal is pulled out. |

| –

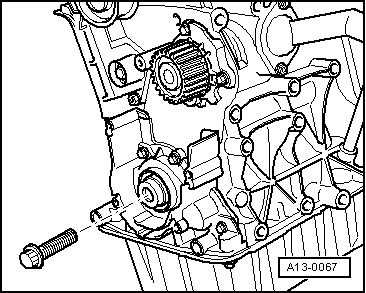

| Clamp flats of oil seal extractor in vice. |

| –

| Remove oil seal with pliers. |

| –

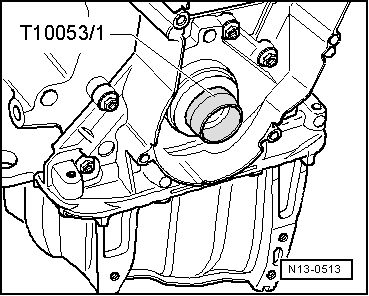

| Clean running surface and sealing surface. |

Note | t

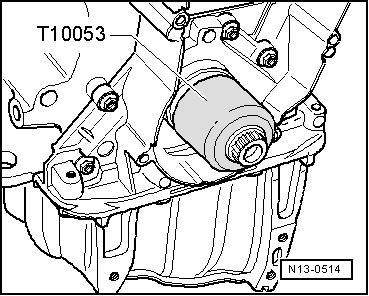

| Renew the bolts tightened with specified tightening angle. |

| t

| Do not lubricate sealing lip and outer rim of oil seal before pressing in. |

|

|

|

Note

Note