A4 Cabriolet Mk2

| Removing timing chains from camshafts - vehicles up to 03.2007 |

| Special tools and workshop equipment required |

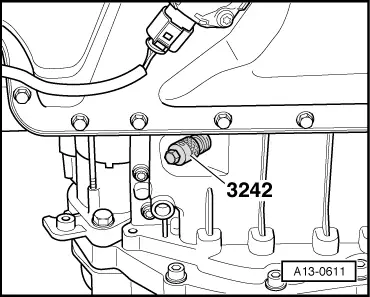

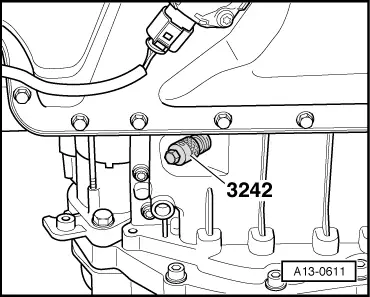

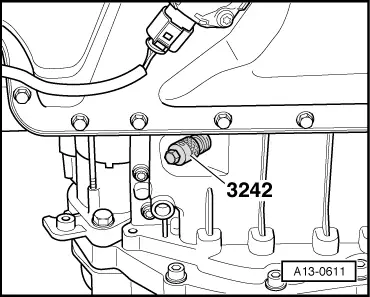

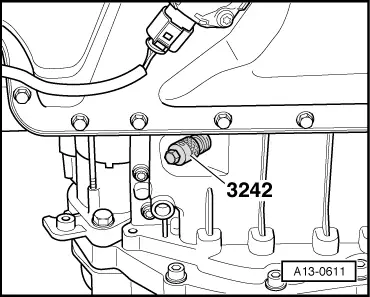

| t | Locking pin -3242- |

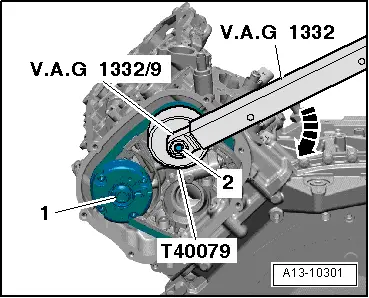

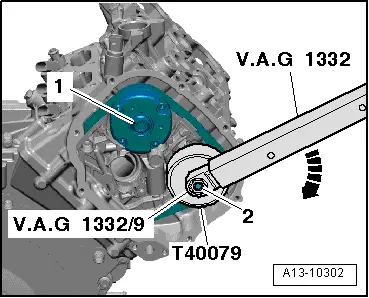

| t | Torque wrench -V.A.G 1332- |

| t | Socket -V.A.G 1332/9- |

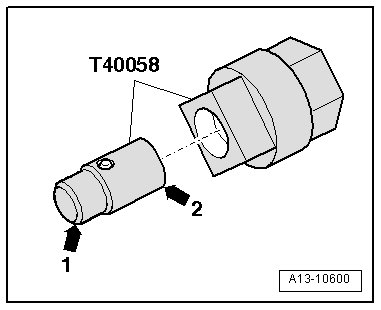

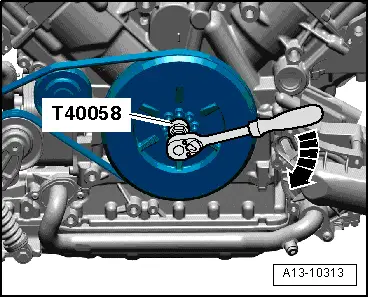

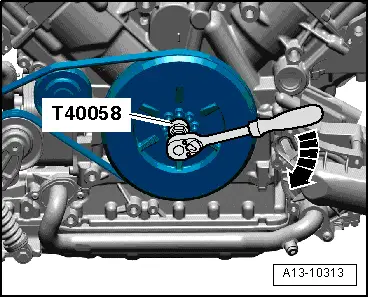

| t | Adapter -T40058- |

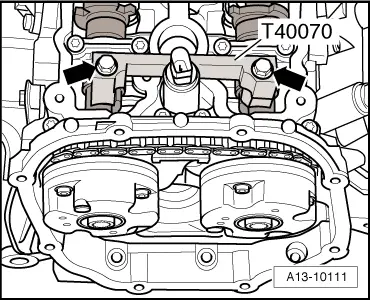

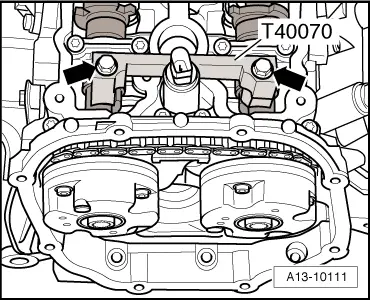

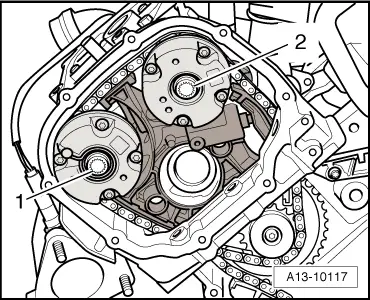

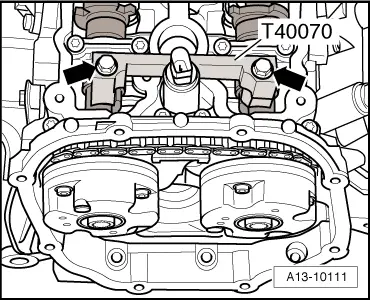

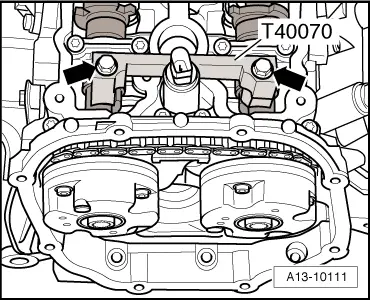

| t | Camshaft clamp -T40070- (2x) |

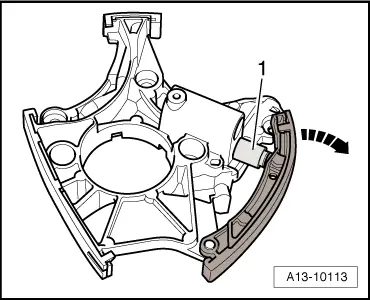

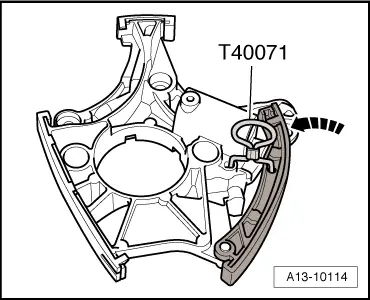

| t | Locking pin -T40071- (2x) |

|

|

Note

Note

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Note

Note |

|

Note

Note

|

|

Note

Note |

|

Note

Note |

|

Note

Note |

|

|

|

|

|

|

|

|

|

|

|

|

|

Note

Note

|

|

|

|

|

|

|

|

Caution

Caution