| –

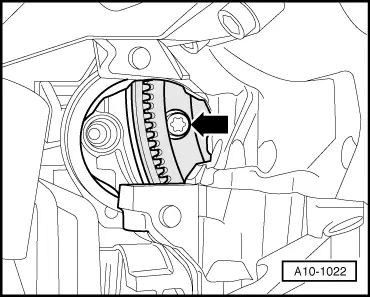

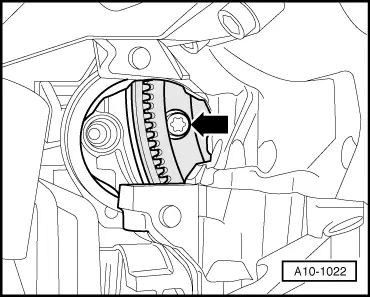

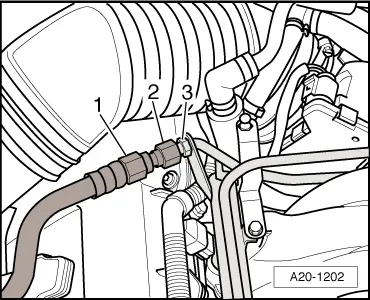

| Before bringing engine and gearbox together, turn torque converter and drive plate on engine so that the holes for one securing bolt are in line with the opening for the starter motor -arrow-. |

| –

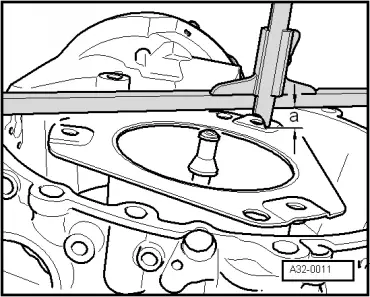

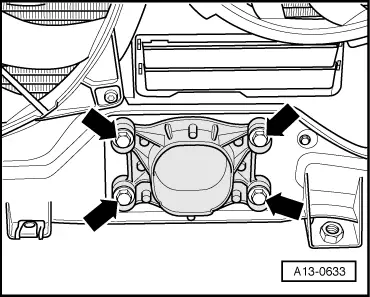

| To secure torque converter on drive plate, use only new ribbed bolts of the correct type (same as original equipment) as specified in → Parts catalogue. |

| –

| Bolt gearbox to engine. |

Caution | Before and during tightening of bolts on engine/gearbox flange, continually check that the torque converter behind the drive plate can be turned. If the converter cannot be turned, it must be assumed that it has not been installed correctly and the drive lugs of the ATF pump and consequently the gearbox will be damaged when the bolts are finally tightened. |

|

Note | t

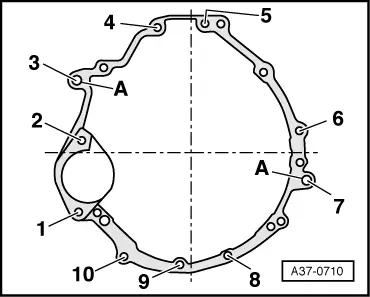

| Tightening torques apply only to lightly greased, oiled, phosphated or black-finished nuts and bolts. |

| t

| Additional lubricant such as engine oil or gearbox oil may be used, but do not use lubricant containing graphite. |

| t

| Do not use degreased parts. |

| t

| Tolerance for tightening torques ± 15%. |

|

|

|

Note

Note

Note

Note

Note

Note

Note

Note Note

Note Note

Note

Caution

Caution WARNING

WARNING