| –

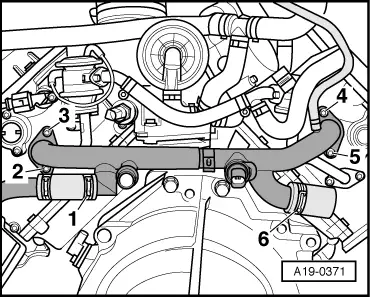

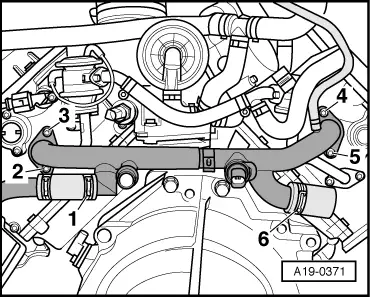

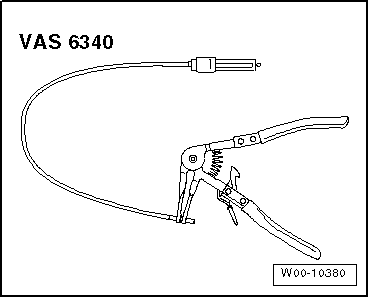

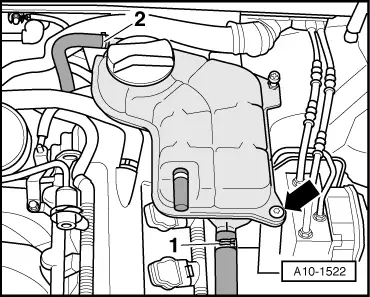

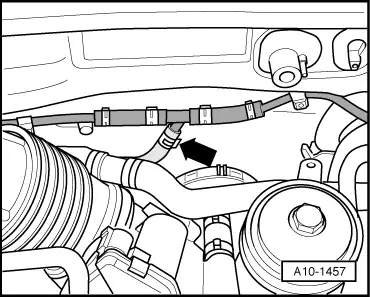

| Release hose clip -1- using hose clip pliers -VAS 6340-. |

| –

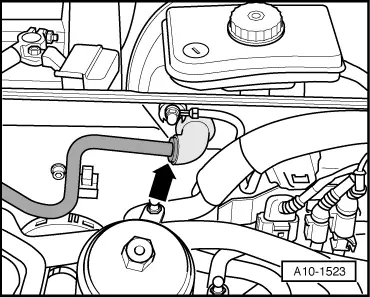

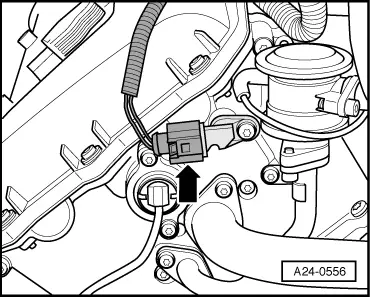

| Release hose clip -6- using hose clip pliers -VAS 6340- and disconnect coolant hose. |

| –

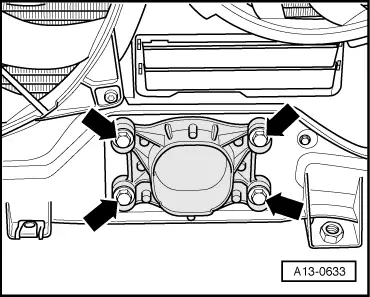

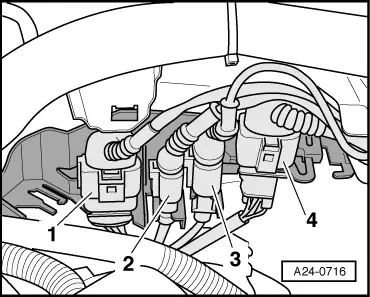

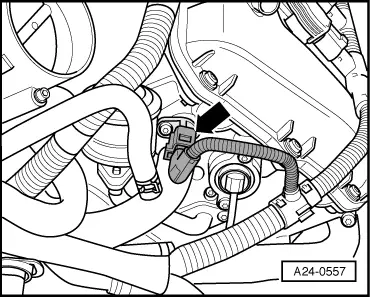

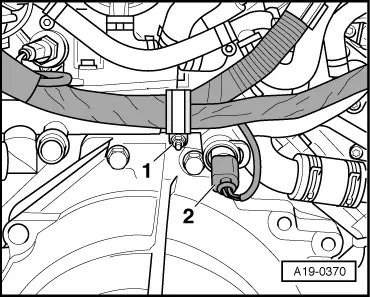

| Remove bolts -2 ... 5-. |

| –

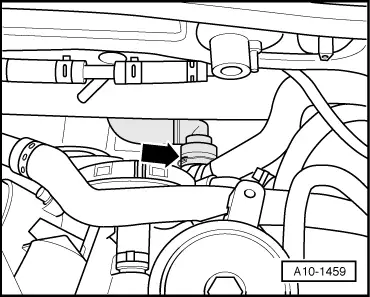

| Detach coolant pipe (rear). |

| Installation is carried out in the reverse order; note the following: |

Note | t

| Secure all hose connections with the correct type of hose clips (same as original equipment) → Parts catalogue. |

| t

| Fit all cable ties in the original positions when installing. |

| –

| Before installing, clean and smooth down sealing surfaces for O-rings as required. |

| –

| Coat new O-rings with acid-free grease (vaseline), fit coolant pipe (rear) and tighten. |

| –

| Install coolant pipe (right-side) → Chapter. |

|

|

|

Note

Note Note

Note

Note

Note

Note

Note