A4 Cabriolet Mk2

| Special tools and workshop equipment required |

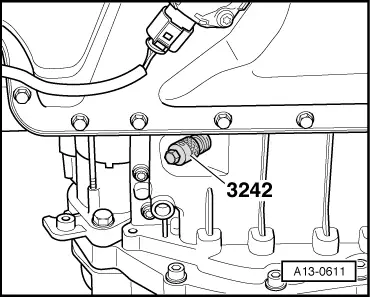

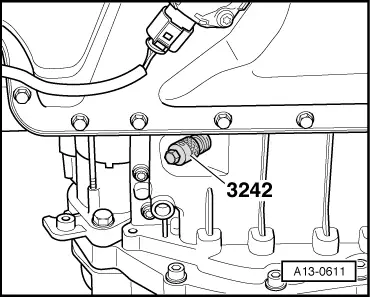

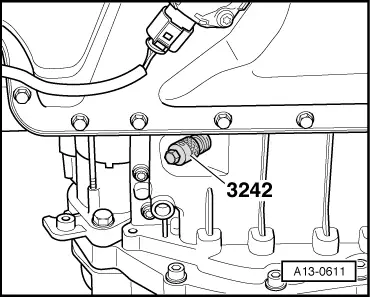

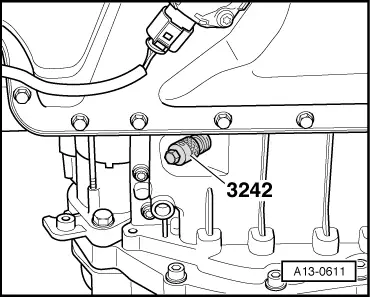

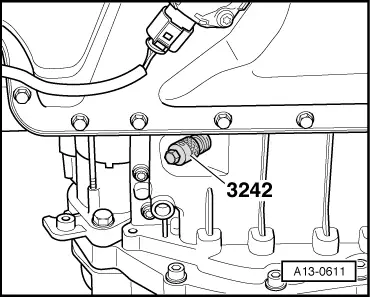

| t | Locking pin -3242- |

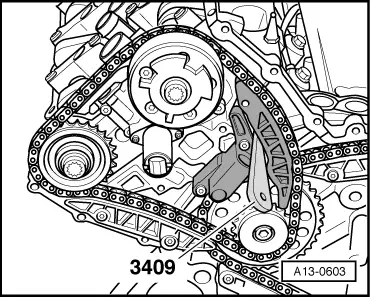

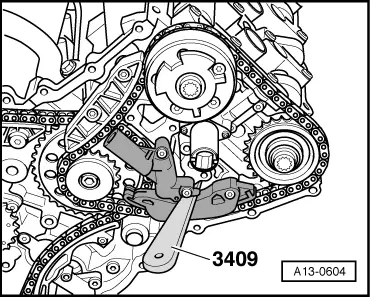

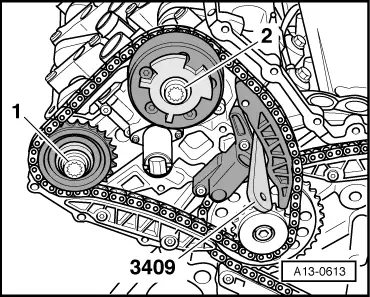

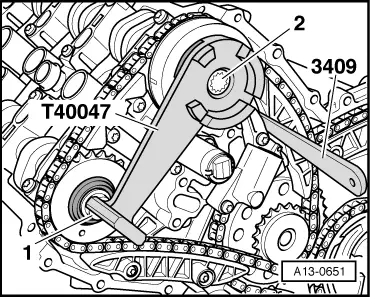

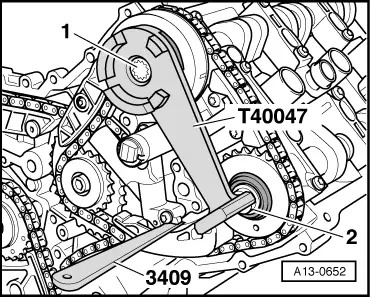

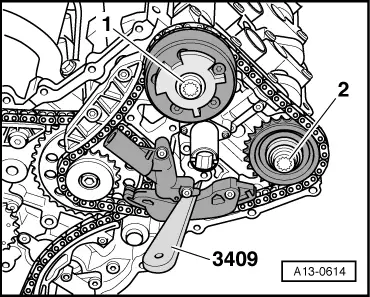

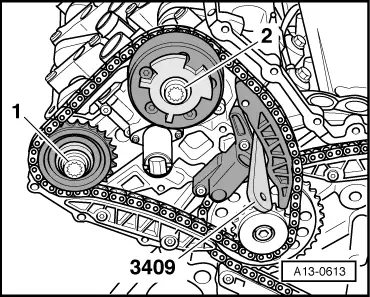

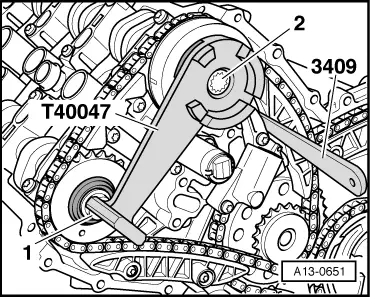

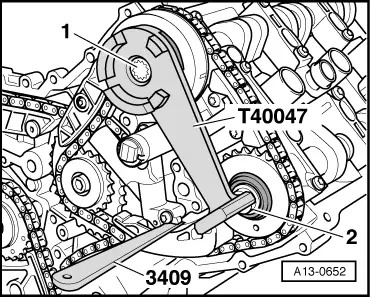

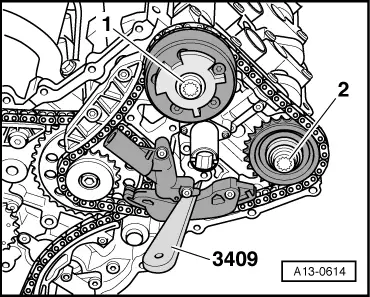

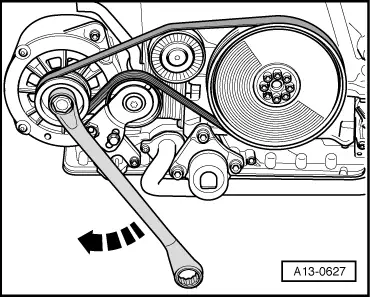

| t | Removal wedge -3409- (2x) |

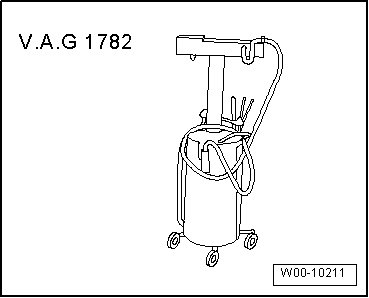

| t | Used oil collection and extraction unit -V.A.G 1782- |

| t | Special wrench -T10035- |

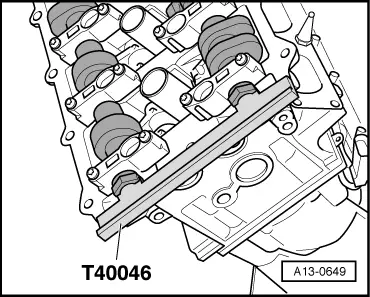

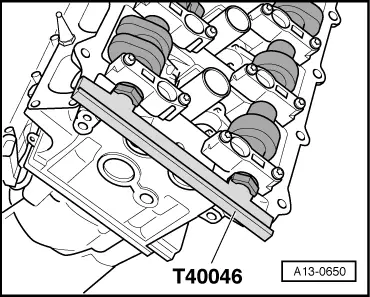

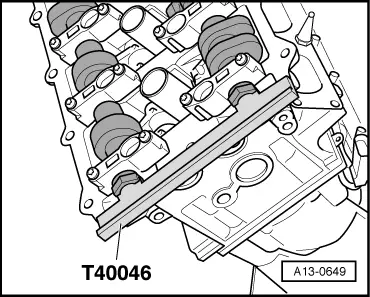

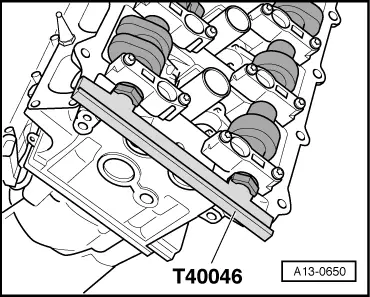

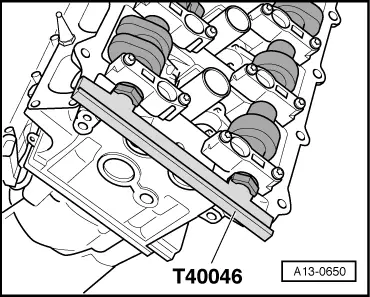

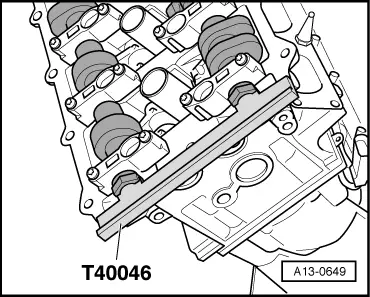

| t | Camshaft clamp -T40046- (2x) |

| t | Setting tool -T40047- |

Note

Note

|

|

Note

Note

|

|

|

|

|

|

Note

Note

|

|

|

|

Note

Note

|

|

Note

Note

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Note

Note

|

|

|

|

|

|

|

|

|

|

|

|

Note

Note

|

|

|

|

Note

Note

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Note

Note

|

|

Note

Note

|

|

|

|

Note

Note

Note

Note

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Note

Note

|

|

|

|

|

|

|

|

|

|

Note

Note

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

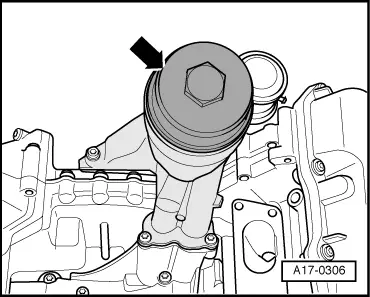

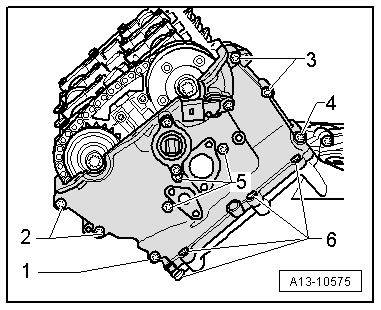

| Component | Nm |

| Camshaft bolts | 100 + 90° → Note → Note |

| Screw plug in top section of sump | 35 |

| Oil drain plug | 50 |

|