A4 Cabriolet Mk2

| Removing and installing injectors |

| Special tools and workshop equipment required |

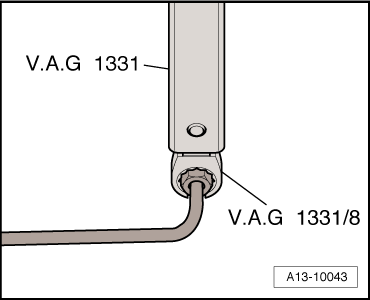

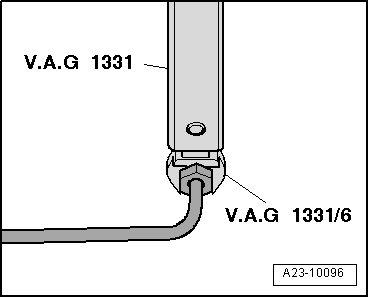

| t | Torque wrench -V.A.G 1331- |

| t | Tool insert, AF 17 -V.A.G 1331/6- |

| t | Socket insert AF 14, flared ring spanner -V.A.G 1331/8- |

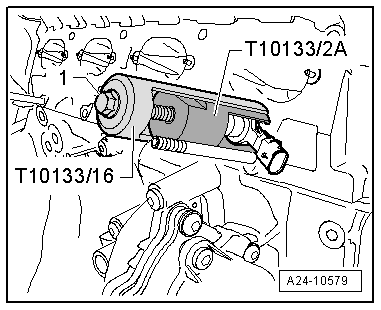

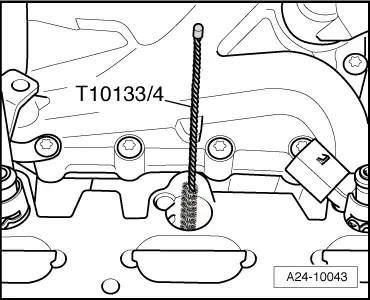

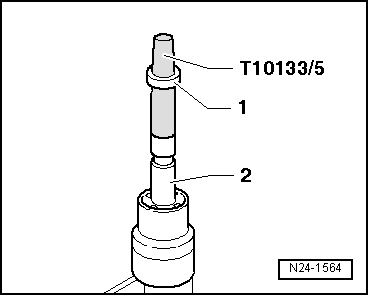

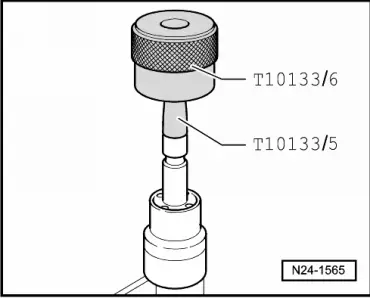

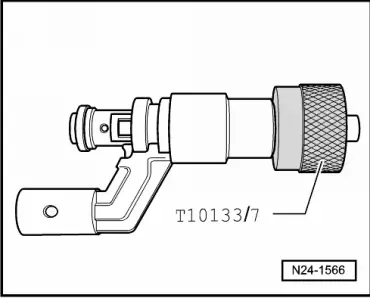

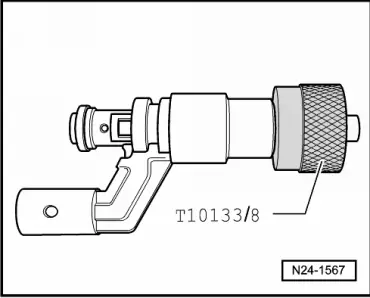

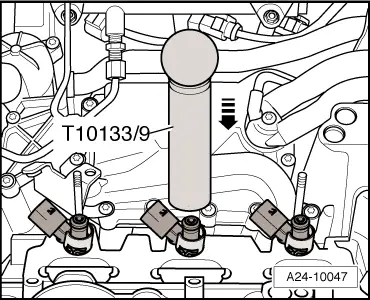

| t | Tool set -T10133- with -T10133/10- |

Note

Note

|

Note

Note

|

|

|

|

Note

Note

|

|

|

|

Note

Note

|

|

|

|

|

|

Note

Note |

|

|

|

Note

Note

|

|

Note

Note

|

|

Note

Note

|

|

|

|

WARNING

WARNING