A4 Mk1

|

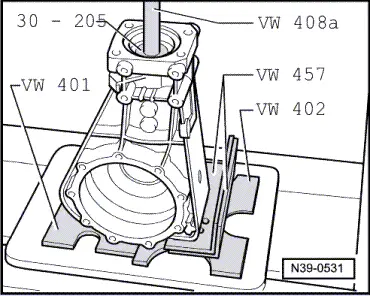

Adjusting drive pinion and crown wheel

Adjusting drive pinion

Notes:

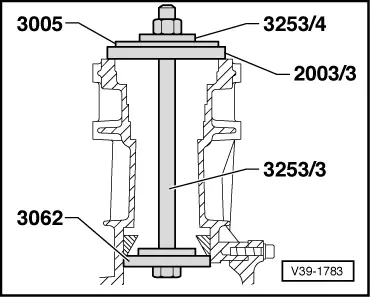

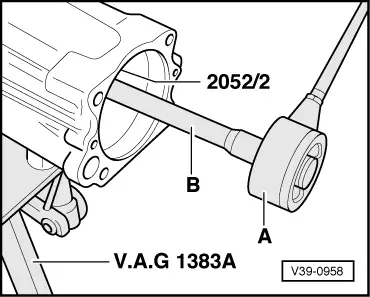

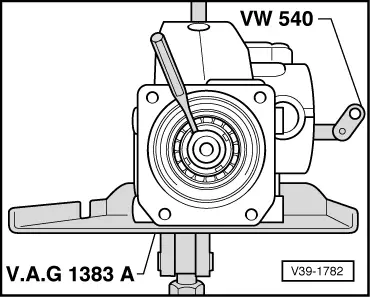

Ascertaining shim "S3" thickness (Setting preload of taper roller bearing for drive pinion) |

|

|

Note: Inscription "Oben" ("top") with thrust pad 3253/4 faces the nut of the puller. |

|

|

|

|

|

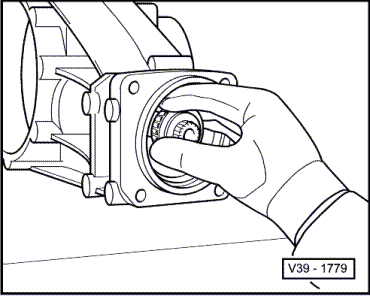

Important:

Wear protective gloves!

Notes:

|

|

|

|

|

|||||||

1) with at least 50 km service | |||||||

|

|

|

|

|

|

|

|

|

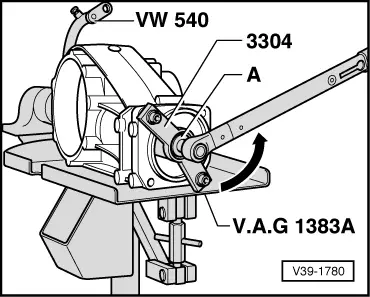

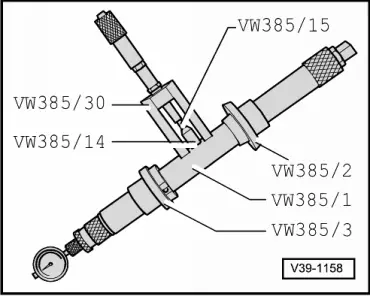

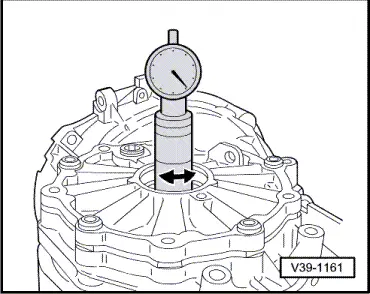

Note: Before performing following measurements turn drive pinion at least five turns in both directions, so that the taper roller bearings settle. Otherwise a false reading will be obtained.

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||||

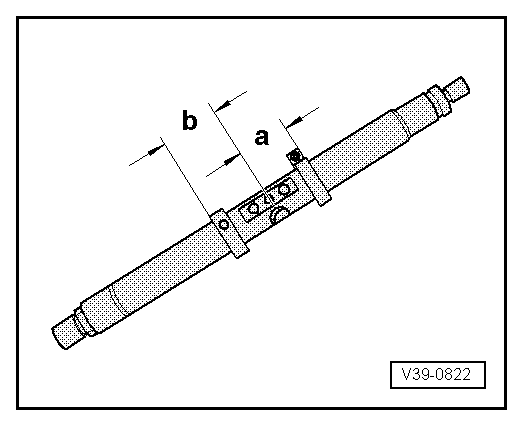

Note: Dimension "e" is required to determine thickness of shim "S3".

Determining shim thickness "S3"

=> Parts List The following shims are available for "S3"

1) Using the shim tolerance variations it is possible to find the exact shim thickness required, insert two shims if necessary.

Notes:

1) with at least 50 km service | |||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

|

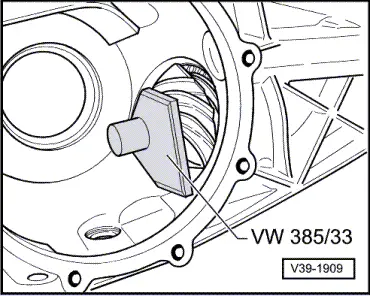

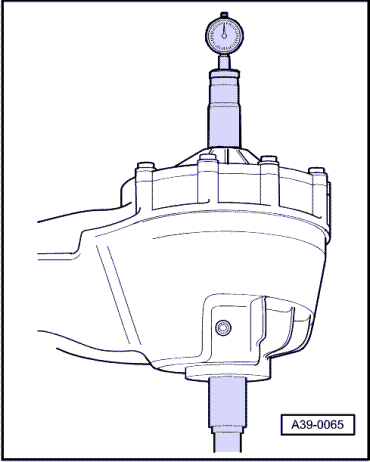

Performing check measurement Checking dimension "r"

|

|

|

|