A4 Mk1

|

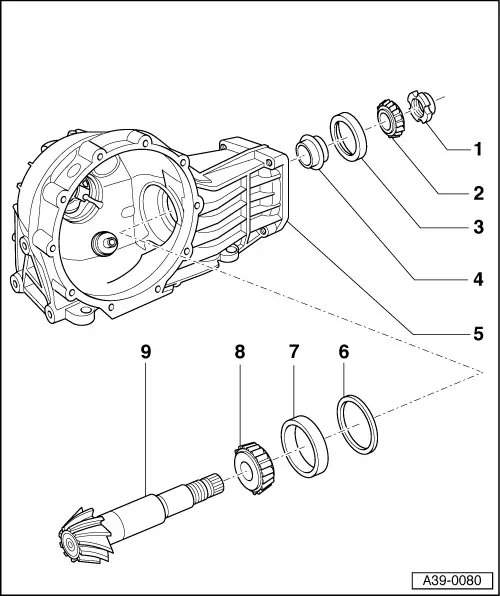

Removing and installing and dismantling and assembling drive pinion

Removing and installing and dismantling and assembling drive pinion

|

|

|

|

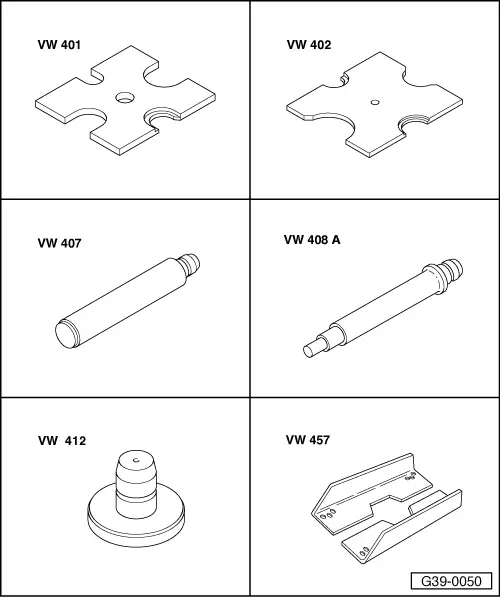

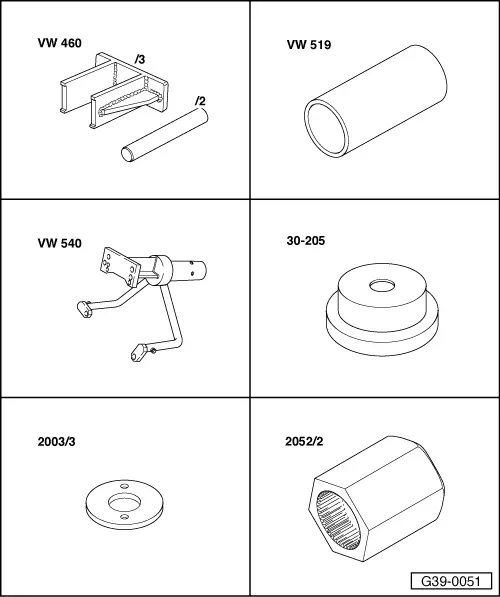

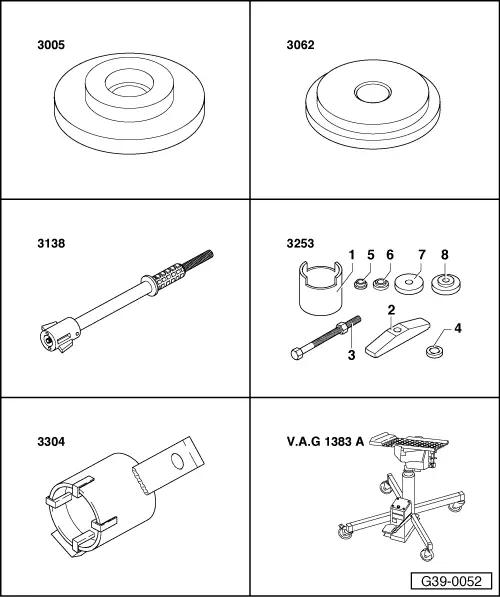

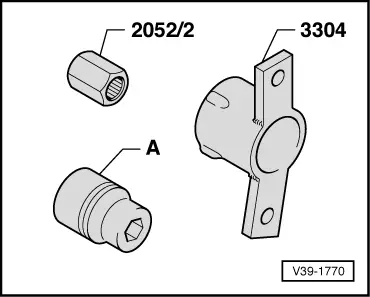

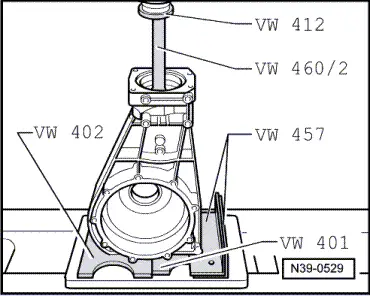

Special tools, testers and auxiliary equipment required

|

|

|

|

|

|

|

|

|

Notes:

|

|

|

|

|

|

|

|

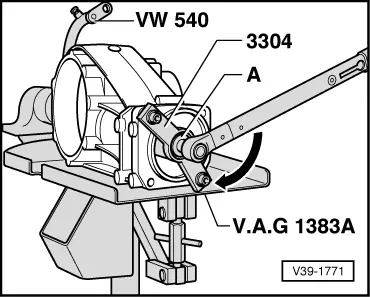

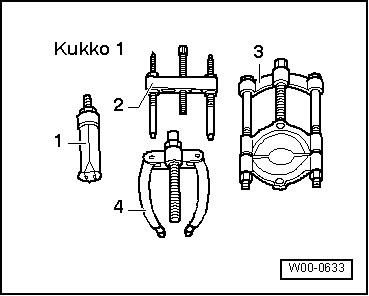

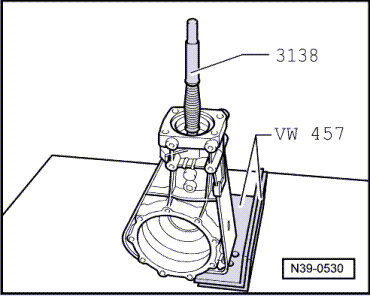

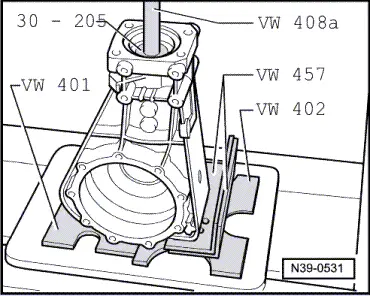

→ Fig.1 Tool for slackening and tightening drive pinion nut

|

|

|

|

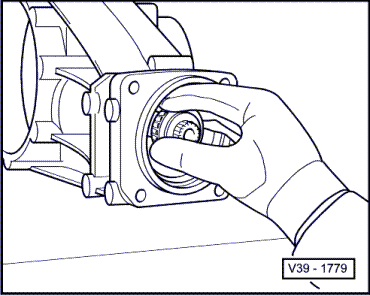

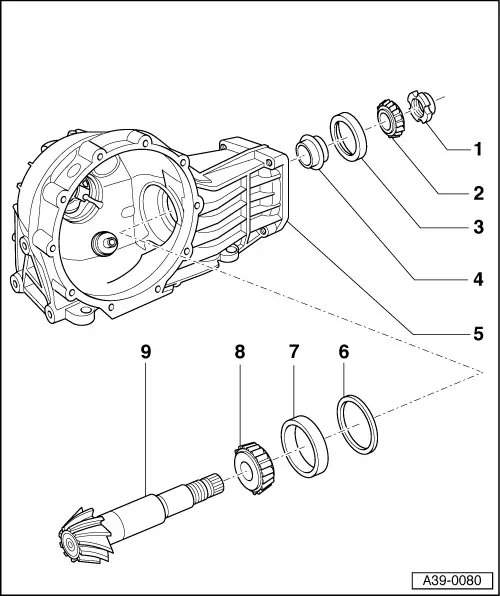

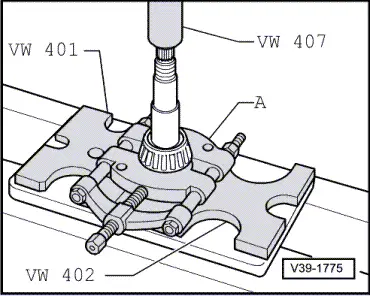

→ Fig.3 Pressing drive pinion out of inner race for small taper roller bearing |

|

|

|

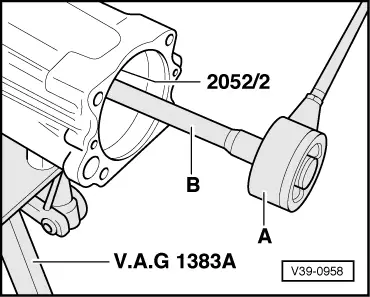

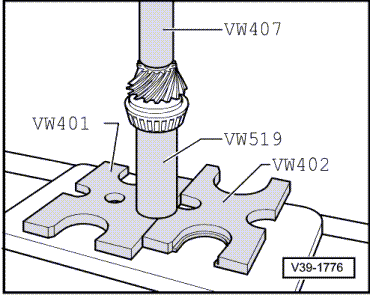

→ Fig.4 Pulling out small taper roller bearing outer race

|

|

|

|

→ Fig.5 Driving out outer race for large taper roller bearing

|

|

|

|

→ Fig.6 Pressing inner race for large taper roller bearing off drive pinion

|

|

|

|

→ Fig.7 Pressing inner race for large taper roller bearing onto drive pinion Important:

Wear protective gloves!

|

|

|

|

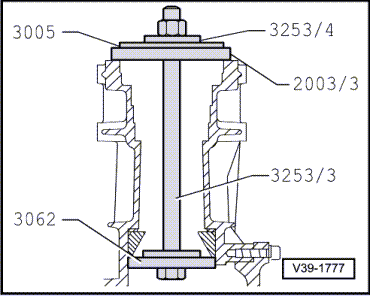

→ Fig.8 Pulling in outer race for large taper roller bearing

Note: Inscription "Oben" ("top") with thrust pad 3253/4 faces the nut of the puller. |

|

|

|

→ Fig.9 Pressing in small taper roller bearing outer race

|

|

|

|

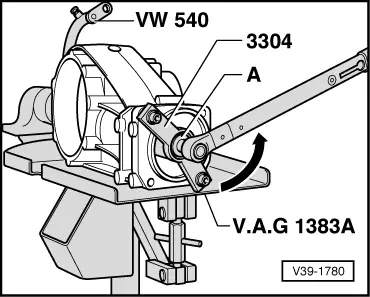

→ Fig11 Tighten nut for drive pinion and adjusting friction torque

Note: If the specified frictional torque is exceeded, the spacer sleeve must be replaced and the adjustment repeated. It is not possible to re-use a spacer sleeve that has been excessively compressed. |

|

|

|

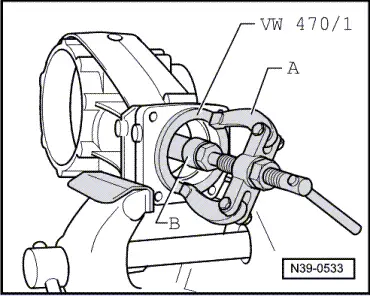

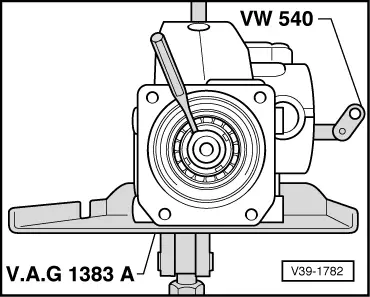

→ Fig.13 Removing nut for drive pinion

|