A4 Mk1

|

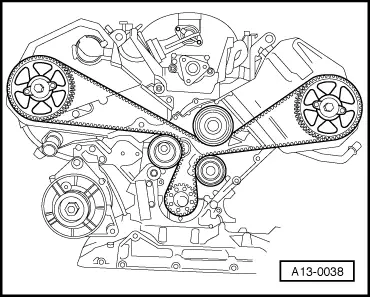

Removing and installing ribbed belt

Removing and installing toothed belt

Removing: |

|

|

|

|

|

|

|

|

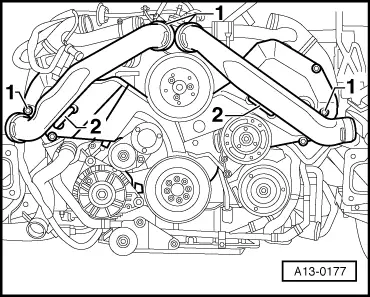

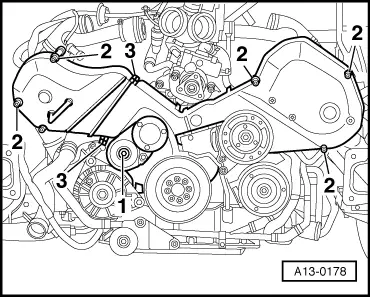

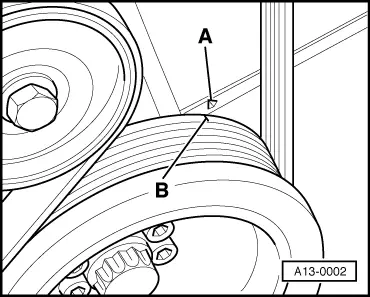

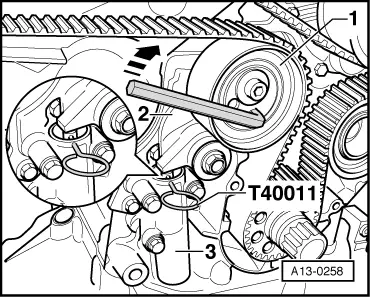

Note: Watch position of retaining strips -2-. |

|

|

|

|

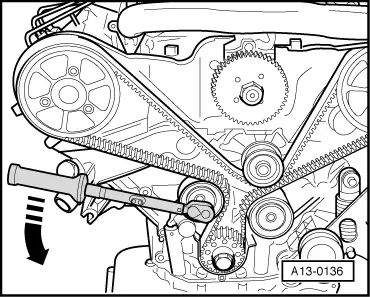

Note: Turn over the engine at the central bolt on the crankshaft.

|

|

|

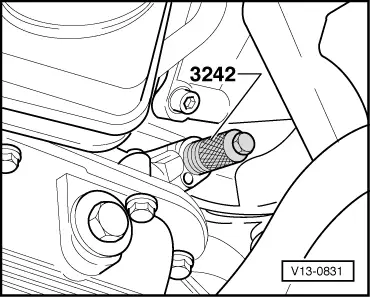

Caution:

Injury risk - do not turn engine while feeling for TDC drilling. |

|

|

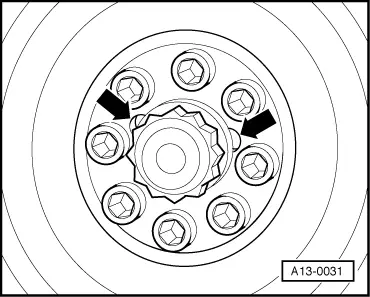

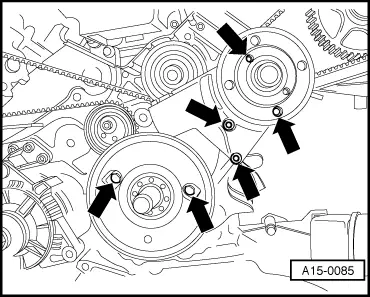

Note: The central bolt does not have to be loosened to remove the vibration damper. |

|

|

Notes:

|

|

|

|

|

|

|

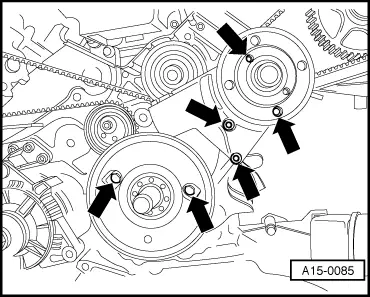

Note: The camshaft sprockets should be just tight enough on the camshaft tapers so that they can still be turned but do not move axially.

|

|

|

|

|

|

|

|

|

|

|

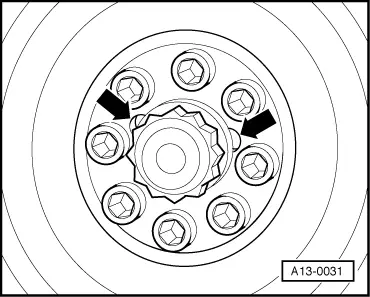

||||||||||||||||||||||

1) The central bolt must always be renewed. 2) Turning in two stages of 90°is also permissible. | ||||||||||||||||||||||