A4 Mk1

|

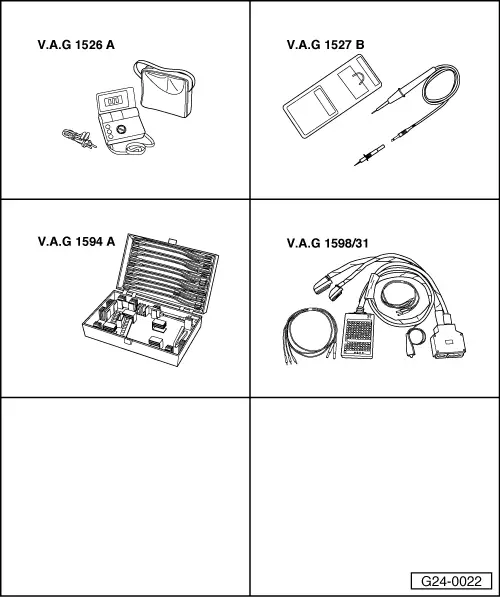

Checking ignition system

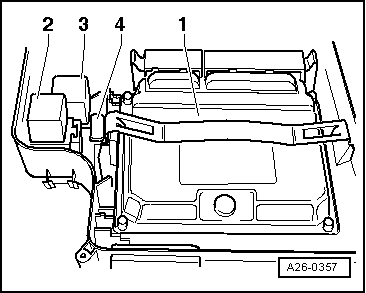

Check ignition coils with output stages

|

|

|

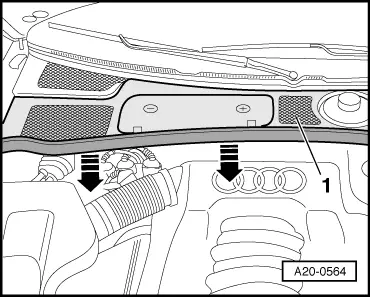

Identify an inoperative or misfiring cylinder as follows:

If misfires are detected:

If no misfires were detected:

or

If the defective cylinder has been identified:

If the fault moves with the spark plug:

If the fault remains in the same cylinder:

If the fault moves with the ignition coil:

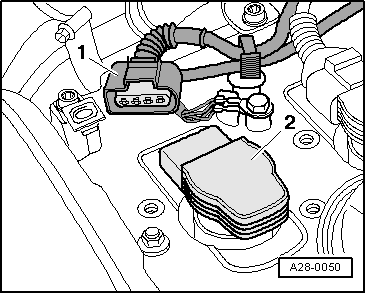

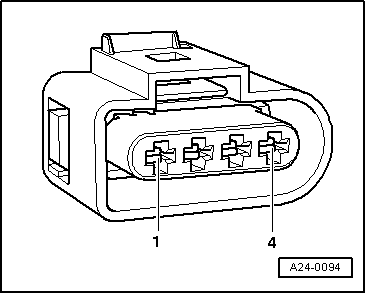

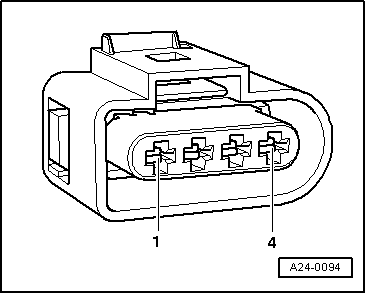

Test earth connection |

|

|

|

|

||||||

If the LED does not light up:

=> Current Flow Diagrams, Electrical Fault-Finding and Fitting Locations If the LED lights up:

Checking power supply Test requirements:

=> Current Flow Diagrams, Electrical Fault-Finding and Fitting Locations |

|

||||

If specified value is attained:

If specified value is not attained: |

|

|

|

|

|

|

|

|

|

|

|

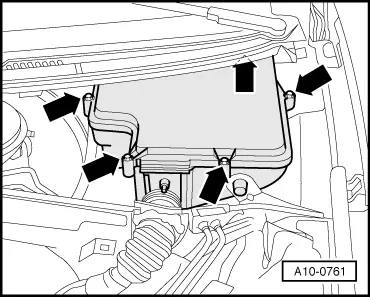

Checking actuation of power output stages

Note: It is important to ensure that no fuel is injected during the test, as this would damage the catalytic converter. Therefore, the connectors on the injectors must be unplugged. |

|

|

|

|

|

If specified values are not attained:

|

|

||||||||||

If no wiring fault is detected:

|