|

Testing ignition system

Testing knock sensors

Notes:

-

◆ To test the operation of the knock sensors, use the function "Read measured value block", Display Groups 012, 013, 014 and 015.

-

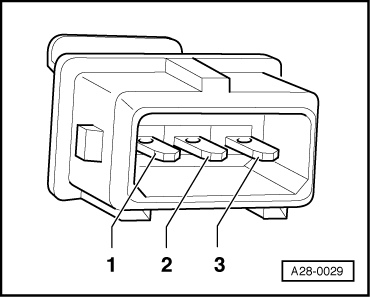

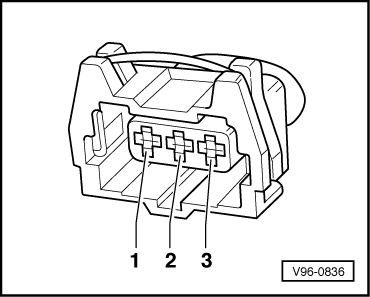

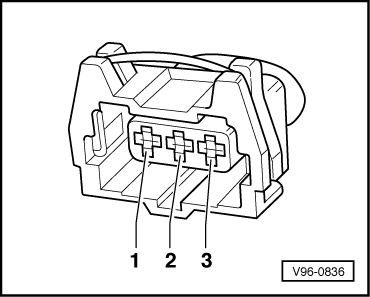

◆ Fitting locations of plug connectors and knock sensors

.

-

◆ It is not possible to carry out an electrical test of the knock sensors themselves. See "Interrogating fault memory", Page 01-7.

-

◆ In order to remove and install the knock sensors the intake manifold must be removed.

-

◆ To ensure that the knock sensors function properly it is important to keep exactly to the specified tightening torque of 20 Nm.

-

◆ Check connectors for corrosion.

-

◆ Use only gold-plated contacts when repairing the contacts in the plug connectors for the knock sensors.

Special tools, testers and auxiliary items

-

◆ Hand multimeter V.A.G 1526 or V.A.G 1526 A

-

◆ Adapter set V.A.G 1594

-

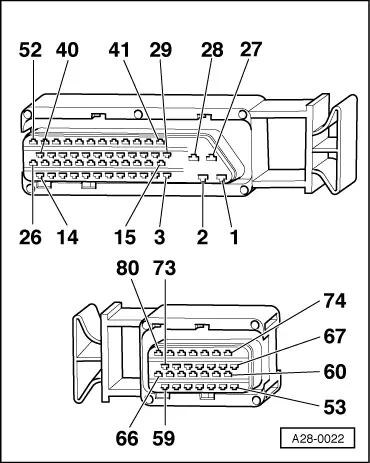

◆ Test box V.A.G 1598/22

Testing knock sensor wiring

-

‒ Unplug the connector for the relevant knock sensor in the engine compartment.

|