-

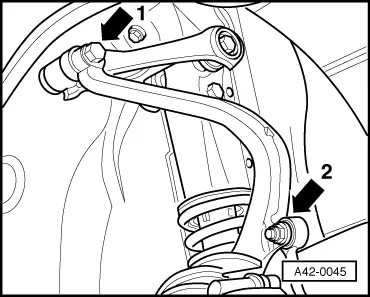

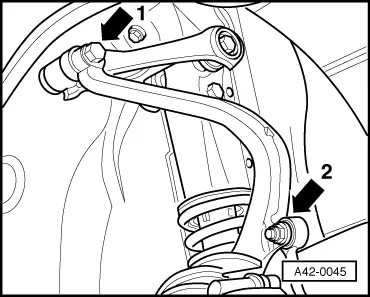

‒ → Unscrew upper link/wheel bearing housing bolted joint -arrow 1-.

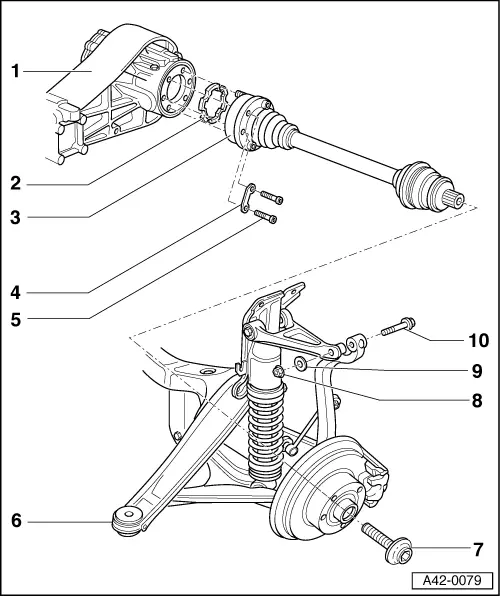

Removing left drive shaft:

-

‒ Remove rear and centre exhaust system silencers.

=> Engine, Mechanics; Repair Group 26; Removing and installing exhaust system components

All vehicles (continued)

-

‒ Lower drive shaft on inside of final drive and pull out of wheel bearing housing.

Installing drive shaft

Install in reverse order.

Bolted joints with bonded rubber bushes must be tightened when vehicle is standing on its wheels.

Otherwise, bonded rubber bush would be subject to torsion and its service life shortened.

-

‒ Pre-tighten bolted joints with bonded rubber bushes to 20 Nm.

-

‒ Screw in new collared bolt and tighten to prescribed torque without additional turn.

-

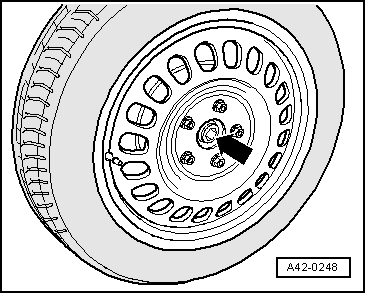

‒ Fit and secure wheel => Page 44-1.

-

‒ Slacken off bolted joints with bonded rubber bushes again.

-

‒ Set vehicle down on its wheels.

-

‒ Bounce vehicle several times.

-

‒ Tighten bolted joints with bonded rubber bushes to prescribed torque.

-

‒ Give collared bolt prescribed further turn.

Tightening torques

|

Component

|

Nm

|

|

Connecting link to wheel bearing housing

|

50 1)

|

|

Upper link to wheel bearing housing

|

70 + 90°2)

|

|

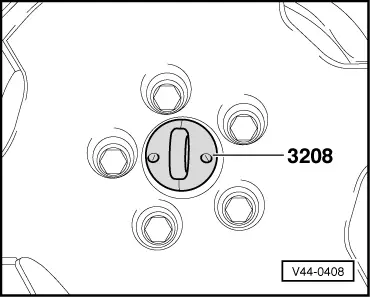

Collared bolt for drive shaft

|

115 + 180°3)

|

|

Drive shaft to flange shaft/differential - M8 bolt

|

40

|

|

Drive shaft to flange shaft/differential - M10 bolt

|

70

|

1) Replace nut

2) Replace bolt and nut

3) Replace bolt

|