A4 Mk1

|

|

|

|

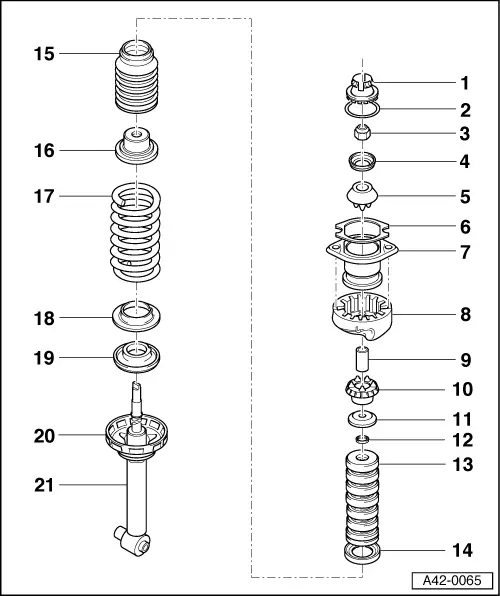

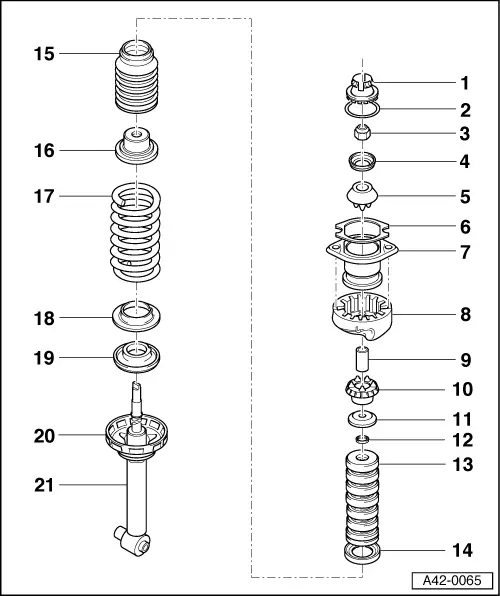

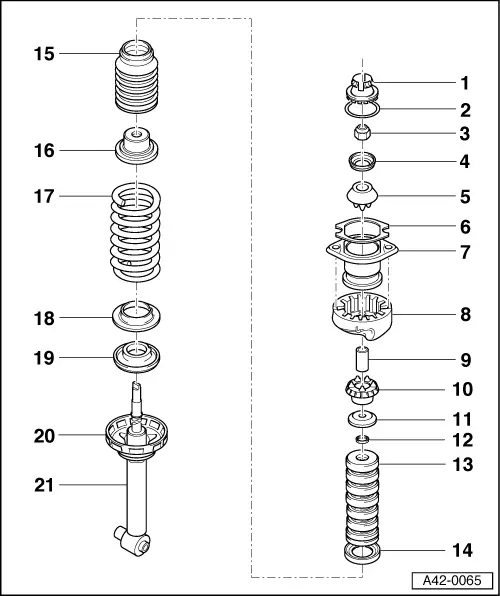

=> Parts List

=> Parts List

=> Parts List |

|

|

=> Parts List

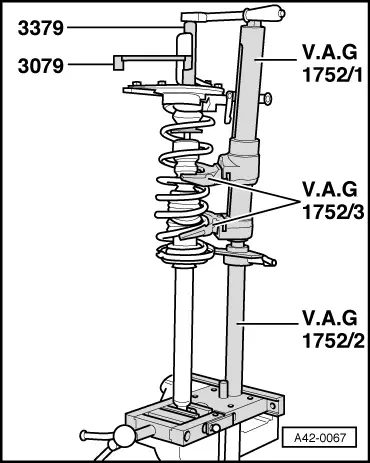

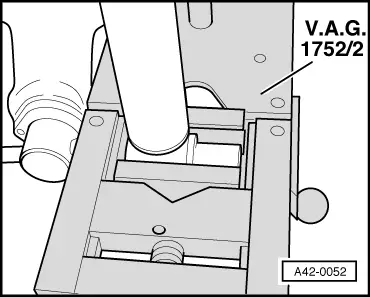

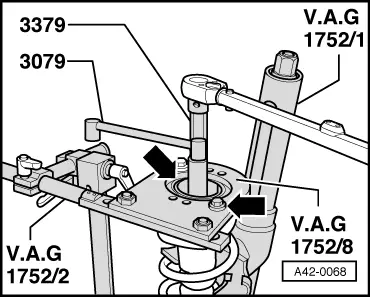

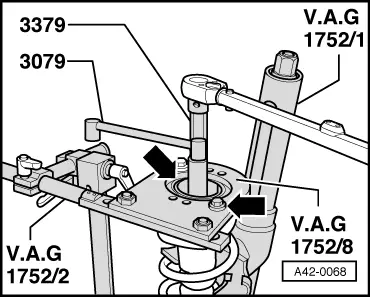

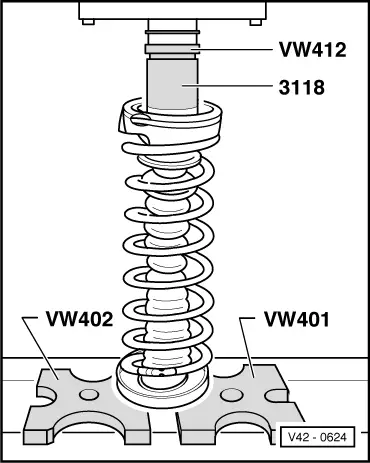

Dismantling and assembling suspension strut Dismantling |

|

|

|

Note: Pay attention to differences in component design between "standard, sports and heavy-duty running gear". |

|

|

|

|

|

|

|

|

|

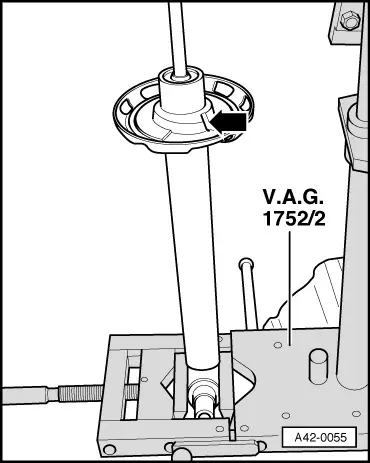

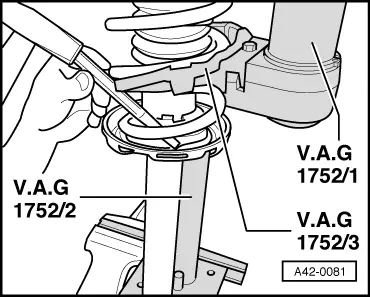

Assembling Note: Left and right suspension strut are identical.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

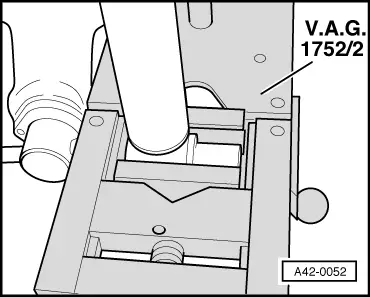

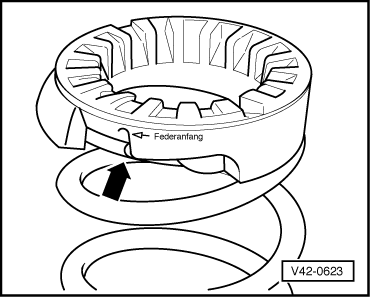

Note: In doing so, take care not to damage surface of spring.

|

|

|

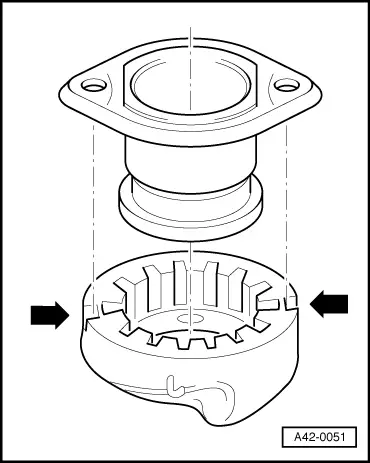

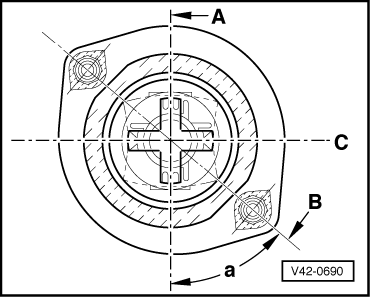

Note: Coat O-ring with silicone grease G 000 405 A2 before fitting cap. |

|

|

Explanatory notes on factory codes (PR numbers) PR numbers are used to facilitate running gear/spring/shock absorber assignment. |

|

|

|

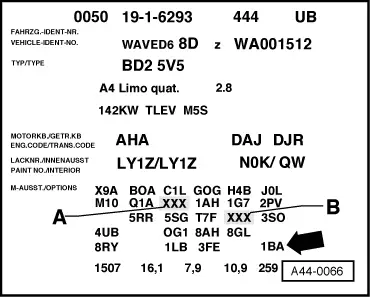

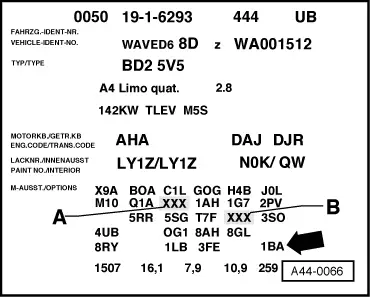

The spring/shock absorber assembly installed in the vehicle can be seen from the corresponding PR number on the vehicle data sticker. → Example of vehicle data sticker

The vehicle data sticker can be found in the spare wheel well and in the Service booklet. The PR no. can be used to find the correct spring/shock absorber combination in the Parts List. |

|

|

|

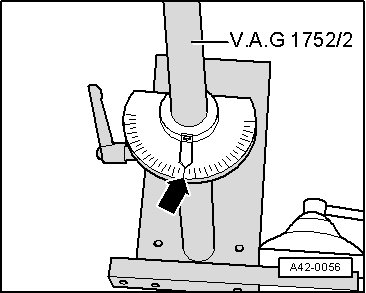

→ The PR no. for the different running gear versions can be seen from the Fig. - arrow -. 1BA = Standard running gear 1BB = Heavy-duty running gear (approx. 20 mm higher) 1BC = Special-purpose vehicles 1BD =Sports running gear (Audi S4) RS4 = Sports running gear (RS4) 1BE = Sports running gear 1BV = Sports running gear (quattro GmbH) 1BQ = Sports running gear (South Africa) 1BT = Heavy-duty running gear (approx. 7 mm higher) 1BP = Heavy-duty running gear (trim position as for 1BA, however with limited bump travel) |