A4 Mk2

|

Note

Note

|

|

|

|

Note

Note

|

|

Note

Note

|

|

|

|

|

|

Note

Note

|

|

|

|

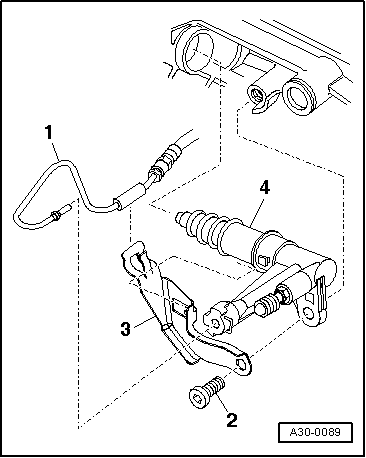

| Component | Nm | ||

| Slave cylinder to gearbox | 23 1) | ||

| Heat shield for drive shaft to gearbox | 23 | ||

| |||

Caution

Caution