A4 Mk2

| Clutch release mechanism - exploded view of components |

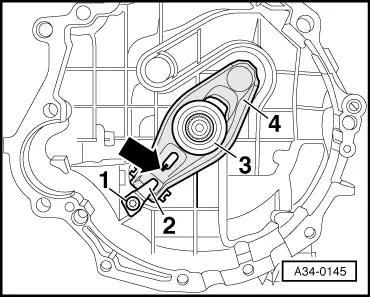

| 1 - | Clutch slave cylinder |

| q | Removing and installing → Chapter |

| q | Do not operate clutch pedal after slave cylinder has been removed. |

| q | Grease lightly before installing → Anchor |

| q | When installing, push in until the securing bolt can be fitted. |

| q | With plug-in connection for hose/pipe assembly |

| q | Disconnecting hose/pipe assembly → Anchor |

| q | Follow correct procedure when bleeding → Chapter |

| q | Tighten bleeder valve to 4.5 Nm. |

| 2 - | Hexagon socket head bolt, 23 Nm |

| q | Slave cylinder to gearbox |

| q | Self-locking |

| q | Renew |

| 3 - | Bracket |

| q | For pipe/hose assembly |

| q | Attached to gearbox together with slave cylinder |

| q | Installing → Anchor |

| q | Bolt onto gearbox with slave cylinder |

| 4 - | Operating rod |

| q | Lubricate end of operating rod with copper grease -Z 381 351 TE- |

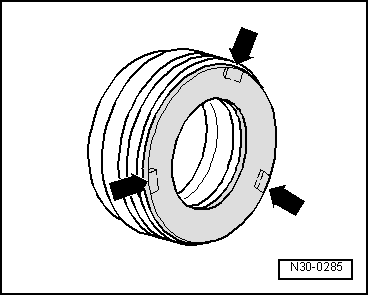

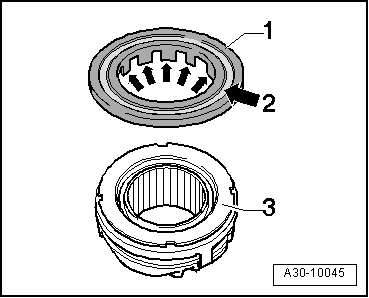

| 5 - | Release bearing |

| q | With or without plastic ring, depending on design |

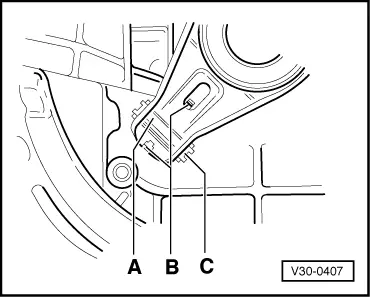

| q | Checking and servicing release bearing with glued plastic ring → Fig. |

| q | Checking release bearing with mechanically attached plastic ring → Fig. |

| q | Renew if groove worn on plastic ring is too deep → Fig. |

| q | Renew bearings if noisy |

| q | Retainer lugs on release bearing must engage in release lever |

| 6 - | Bolt, 25 Nm |

| q | Self-locking |

| q | Renew |

| 7 - | Leaf spring |

| 8 - | Clutch release lever |

| q | Several versions available. For correct allocation refer to → Parts catalogue |

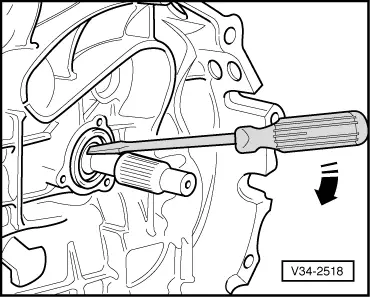

| q | Removing → Fig. |

| q | Must engage in the lugs in intermediate piece when installed → Fig. |

| q | Before installing, lubricate area which makes contact with operating rod of slave cylinder with copper grease -Z 381 351 TE- |

| 9 - | Bolt, 15 Nm |

| q | 3 x |

| 10 - | Guide sleeve |

| 11 - | Oil seal |

| q | For input shaft |

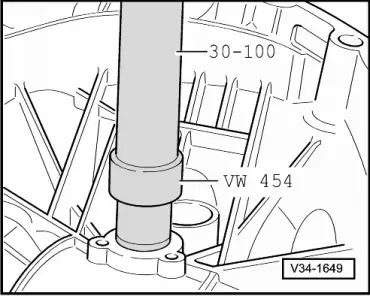

| q | Removing → Fig. |

| q | Installing → Fig. |

| q | Pressing-in depth (factory): 3.5 mm, Pressing-in depth (repairs): 4.5 mm |

| 12 - | Intermediate piece |

| q | Renew if damaged |

| 13 - | Gearbox |

Note

Note

|

|

|

|

|

|

Note

Note

|

|

Note

Note

|

|