| –

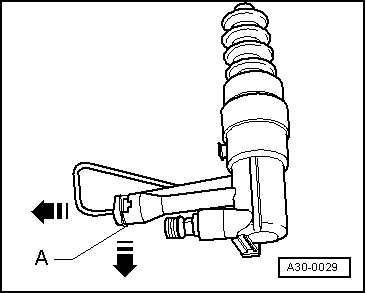

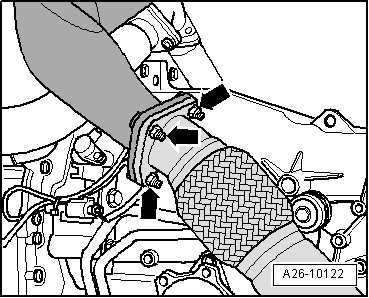

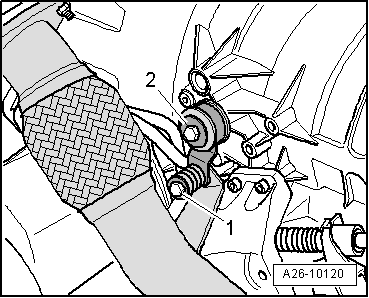

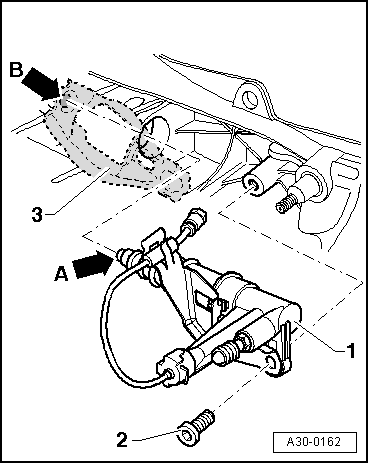

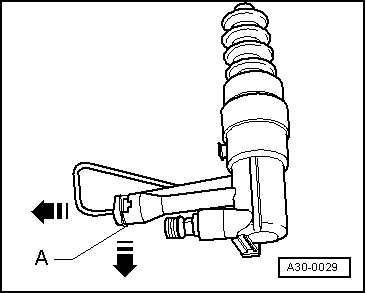

| Press retaining clip -A- in clutch slave cylinder onto limit stop. |

| –

| Push pipe/hose assembly -B- onto connection on clutch slave cylinder so that retaining clip snaps into place. |

| –

| Check secure seating of pipe/hose assembly. |

Caution | t

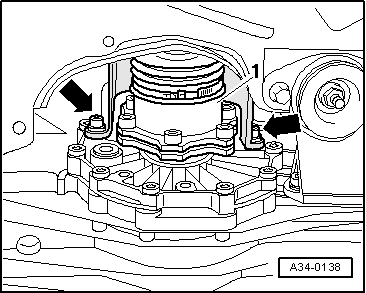

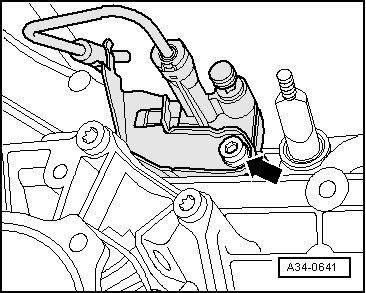

| After installing the slave cylinder press the clutch pedal carefully. |

| t

| If you feel an unusually strong point of resistance when depressing the clutch pedal, you must not press it down further. |

| t

| The operating rod of the slave cylinder is likely to have been guided past the clutch release lever. |

| t

| The slave cylinder would then be destroyed once pedal force exceeds approx. 300 N. |

| t

| For comparison: normal pedal force is approx. 115 N. |

|

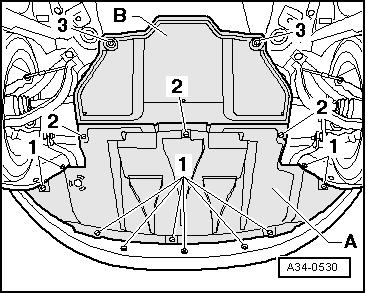

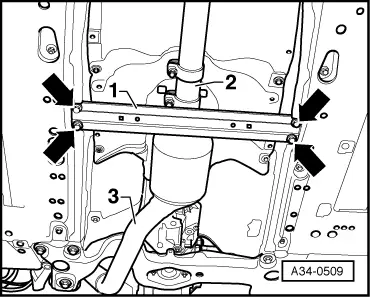

| Vehicles with V6 TDI engine: |

| –

| Install front exhaust pipe and perform stress-free alignment → Rep. Gr.26. |

| –

| Install heat shield for drive shaft (left-side). |

| Continued for all vehicles: |

| –

| If the pipe-hose assembly was disconnected at the slave cylinder, the clutch system has to be bled after installing slave cylinder → Chapter. |

|

|

|

Note

Note

Note

Note

Note

Note

Note

Note

Caution

Caution