A4 Mk2

| Dismantling and assembling bearing housing |

| Special tools and workshop equipment required |

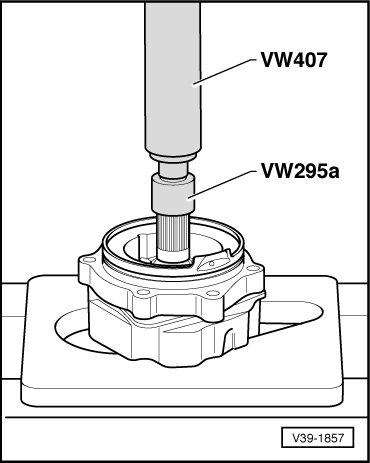

| t | Adapter -VW 295 A- |

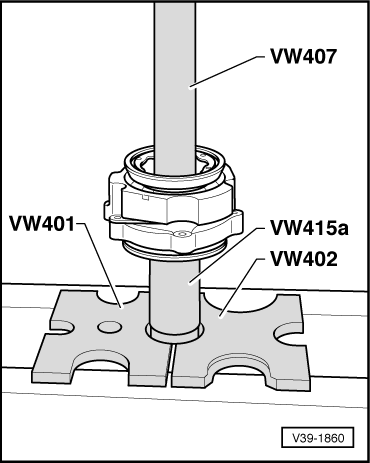

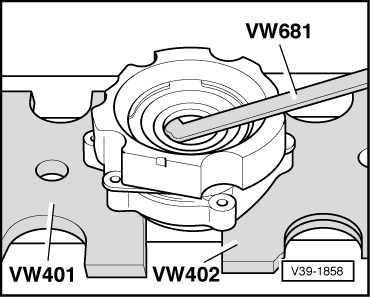

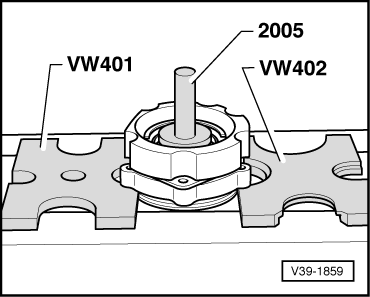

| t | Thrust plate -VW 401- |

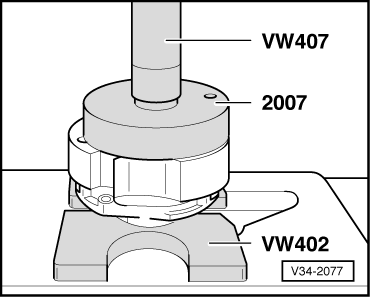

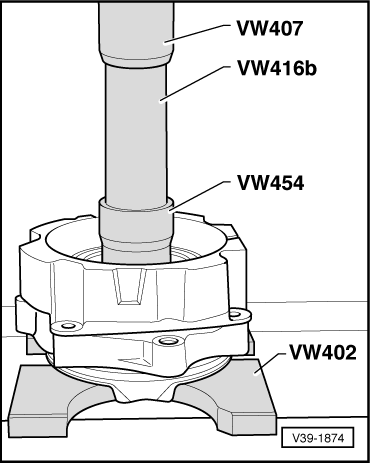

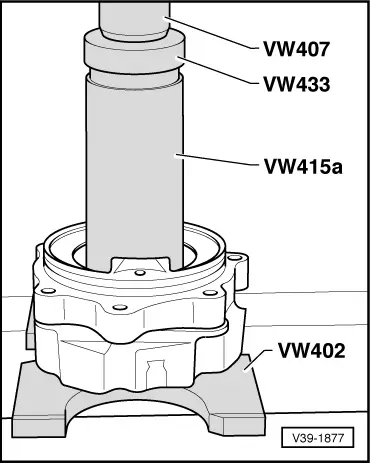

| t | Thrust plate -VW 402- |

| t | Press tool -VW 407- |

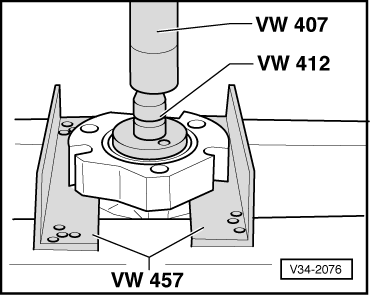

| t | Press tool -VW 412- |

| t | Tube -VW 415 A- |

| t | Tube -VW 416 B- |

| t | Press tool -VW 433- |

| t | Press tool - VW 454- |

| t | Support rails -VW 457- |

| t | Oil seal extractor lever -VW 681- |

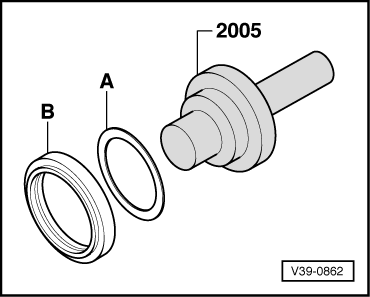

| t | Punch -2005- |

|

|

|

|

| Exploded view |

| 1 - | Circlip |

| 2 - | Ball bearing for flange shaft |

| q | Pressing out → Fig. |

| q | Pressing in → Fig. |

| 3 - | O-ring |

| q | Renew |

| q | Oil lightly before installing. |

| 4 - | Bearing housing |

| 5 - | Oil seal |

| q | Pulling out → Fig. |

| q | Preparing for installation → Fig. |

| q | Driving in → Fig. |

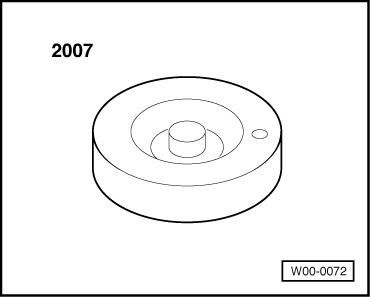

| 6 - | Damper weight |

| q | Not fitted on all versions |

| q | For correct version, refer to → Electronic parts catalogue |

| q | Pressing off → Fig. |

| q | Pressing on → Fig. |

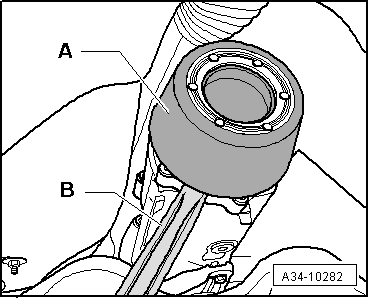

| 7 - | Vibration damper |

| q | Only on vehicles with 4-cyl. TDI engine |

| q | For correct version, refer to → Electronic parts catalogue |

| q | Sealing cap -arrow- must not be removed |

| q | Removing → Fig. |

| 8 - | Flange shaft |

| q | For correct version, refer to → Electronic parts catalogue |

| q | Pressing out → Fig. |

| q | Pressing in → Fig. |

|

|

|

|

|

|

|

|

Note

Note

|

|

|

|

|

|

|

|

|

|