| –

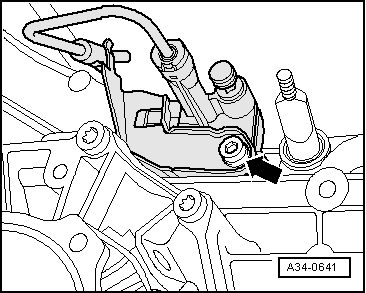

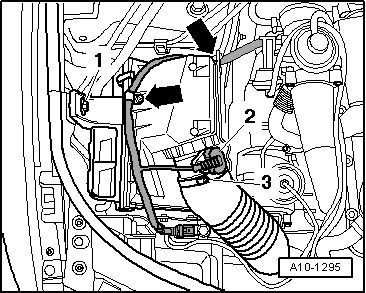

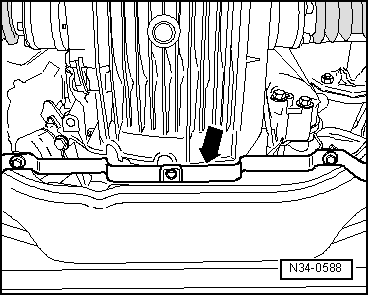

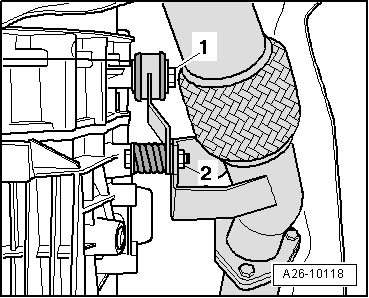

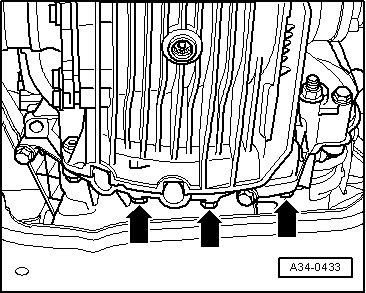

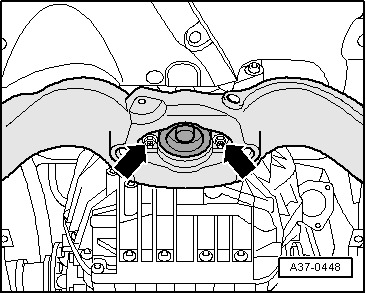

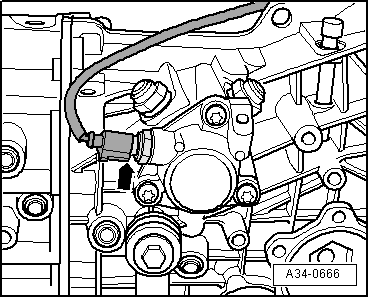

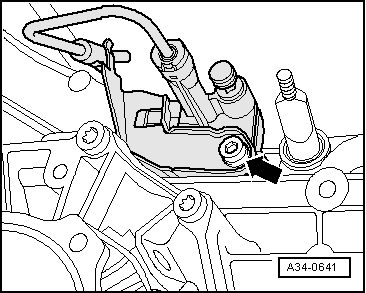

| Remove clutch slave cylinder from gearbox -arrow- and secure with wire, do not open pipe/hose system. |

Caution | Do not depress clutch pedal after removing clutch slave cylinder. The slave cylinder would then be destroyed once pedal force exceeds approx. 300 N. |

|

| –

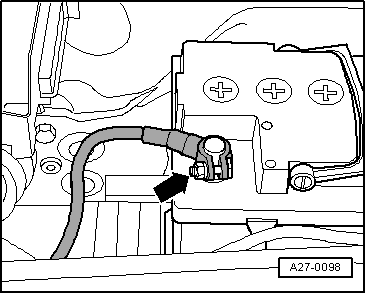

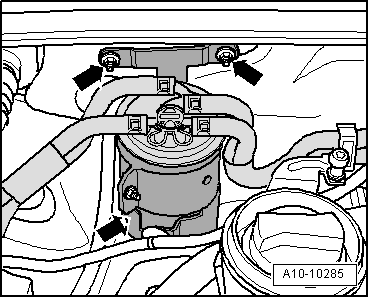

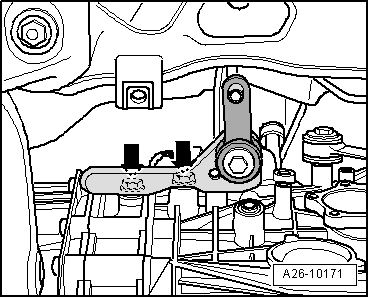

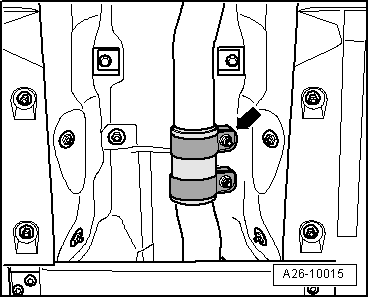

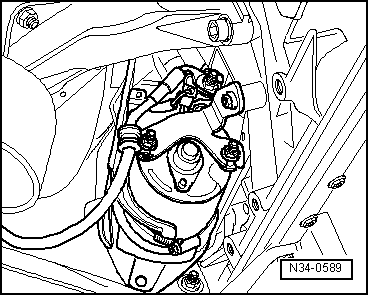

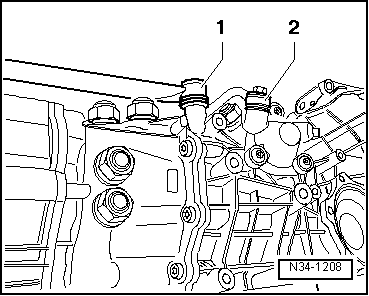

| If fitted, remove retaining clips/cable ties together with Lambda probe wires from top of gearbox. |

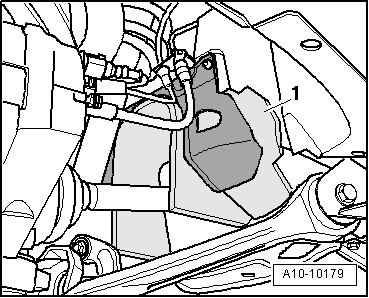

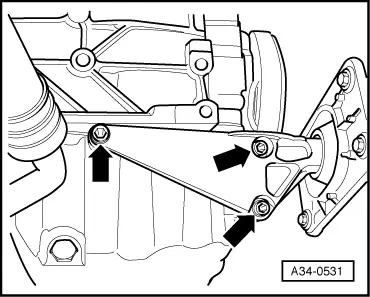

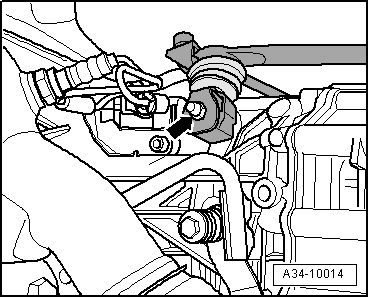

Note | When lowering gearbox, make sure there is sufficient clearance from drive shafts. |

| –

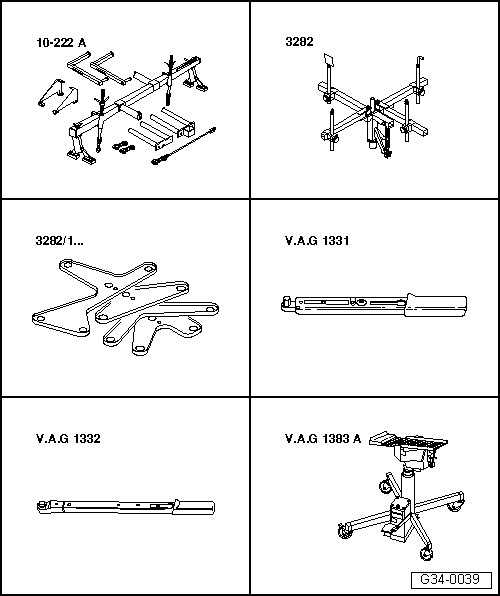

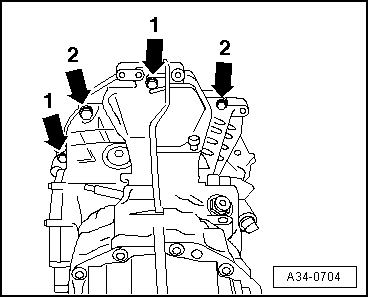

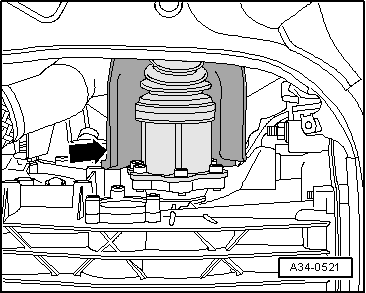

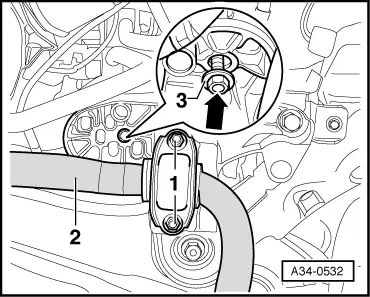

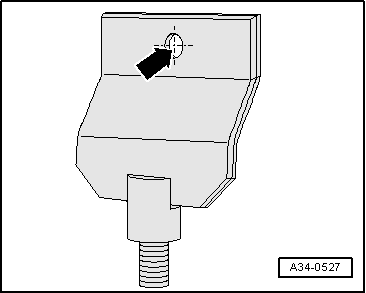

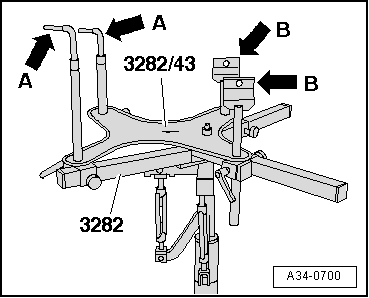

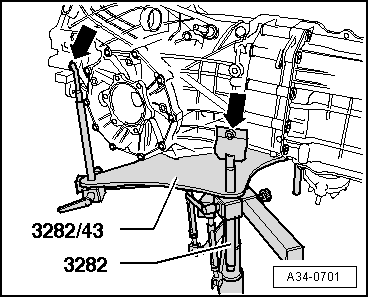

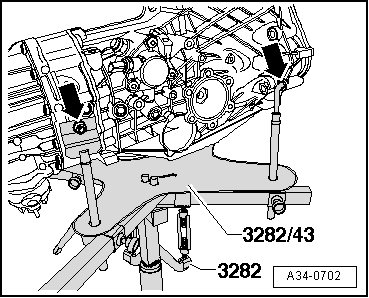

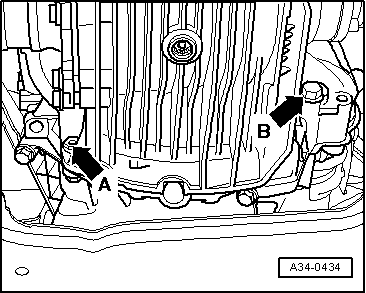

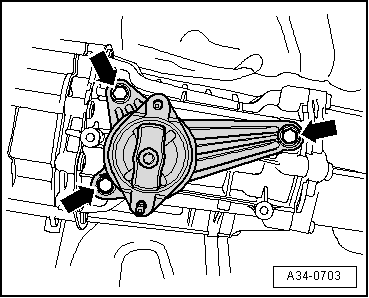

| Before carrying out assembly work, secure gearbox to assembly stand, using engine and gearbox support -VW 540- → Chapter. |

|

|

|

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Caution

Caution