| –

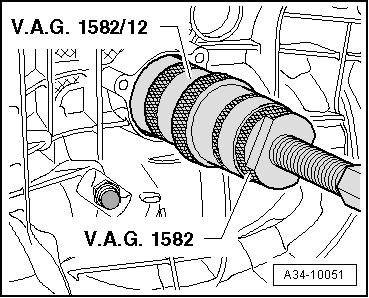

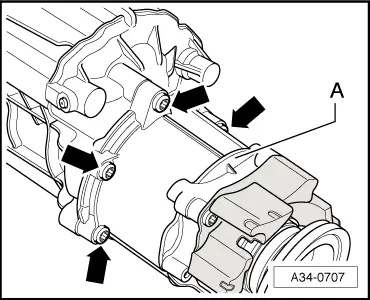

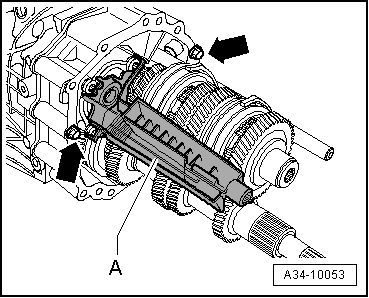

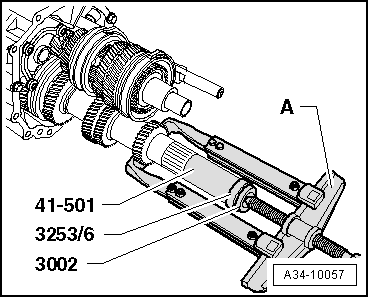

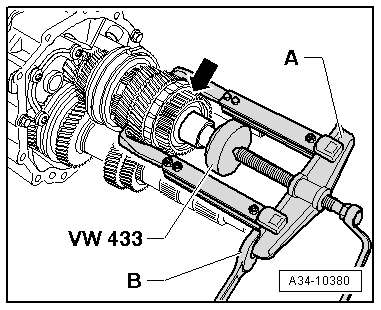

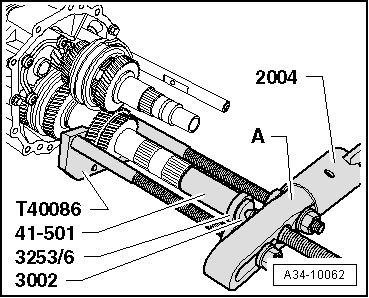

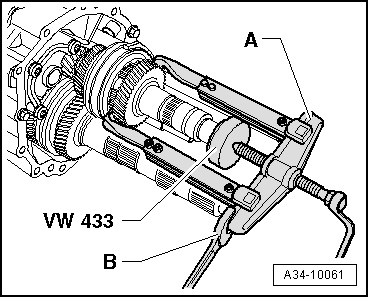

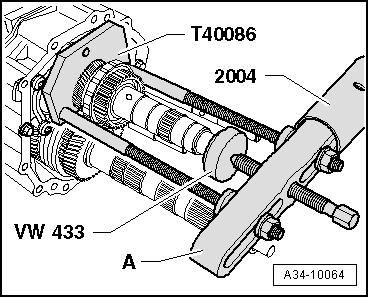

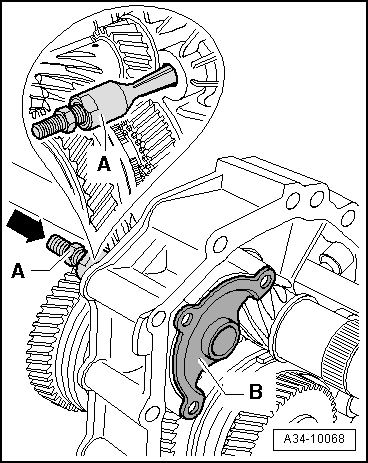

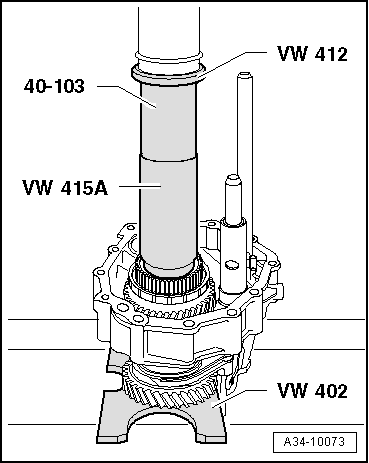

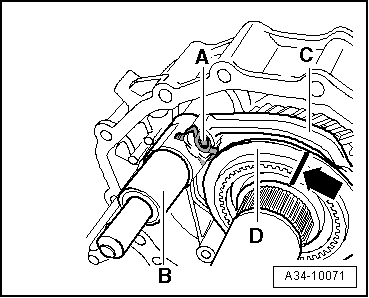

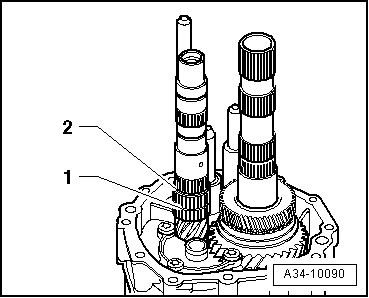

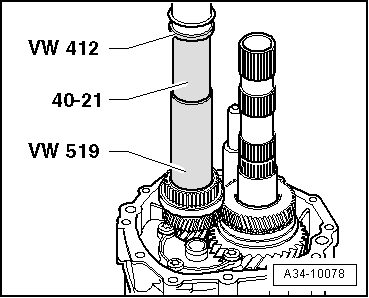

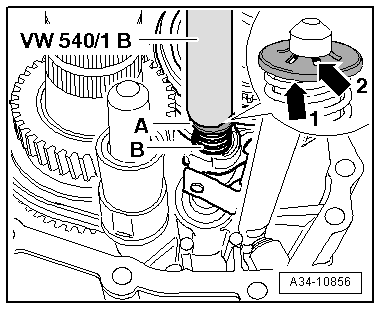

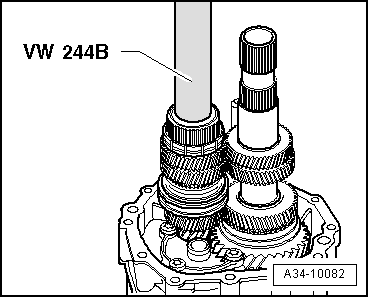

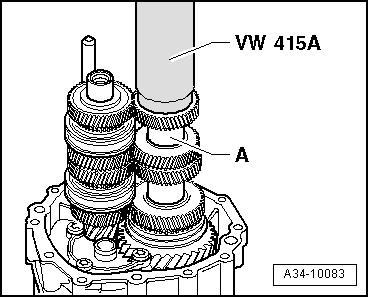

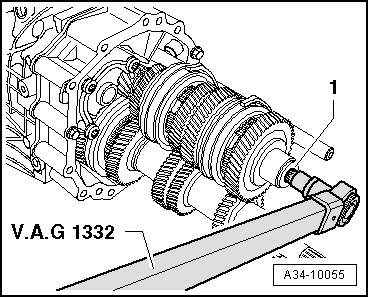

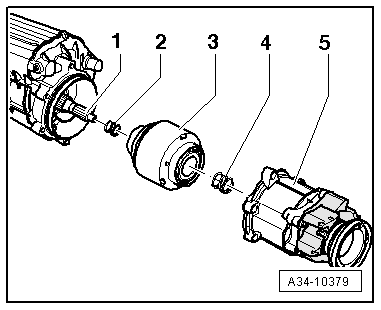

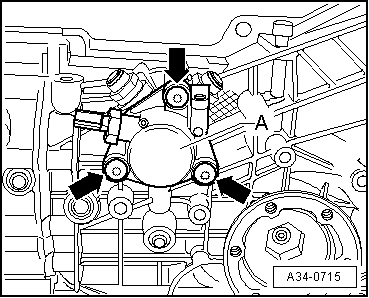

| Press off synchro-hub for reverse gear from hollow shaft. |

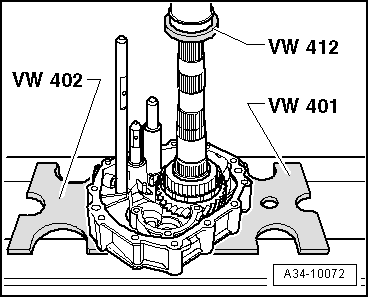

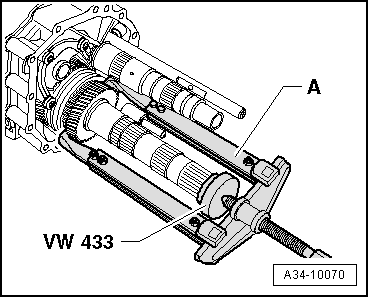

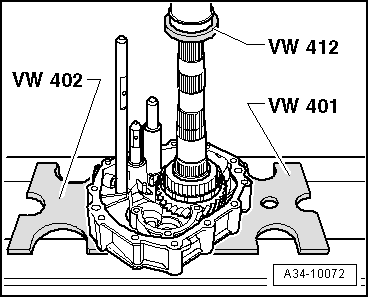

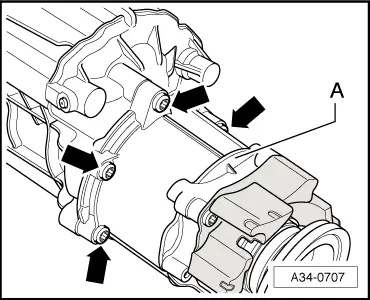

Note | Place the bearing housing onto thrust plates -VW 401- and -VW 402- so that the hollow shaft and selector rods are not damaged when pressing off the synchro-hub. |

| –

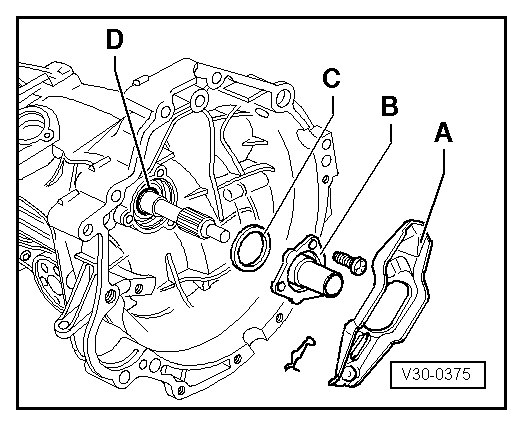

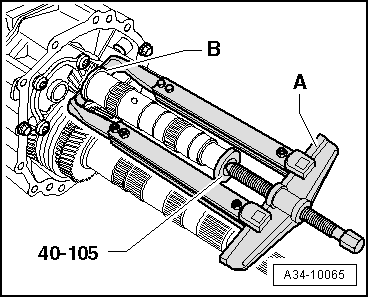

| Detach reverse selector gear, needle bearing for reverse selector gear and reverse gear synchro-hub. |

| –

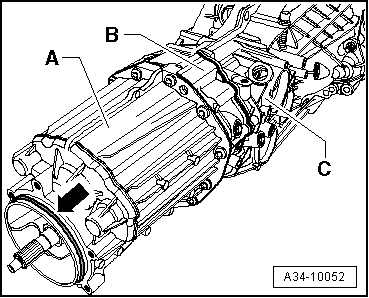

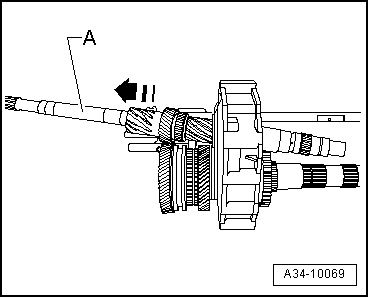

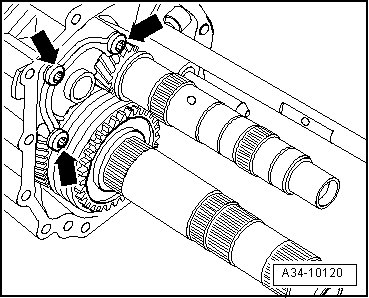

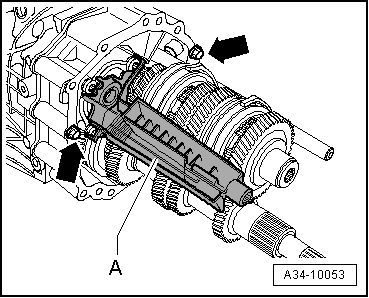

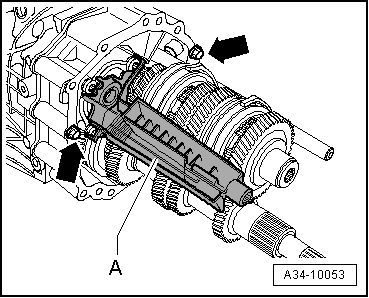

| Guide hollow shaft out of selector fork for 1st and 2nd gear and bearing housing. |

| l

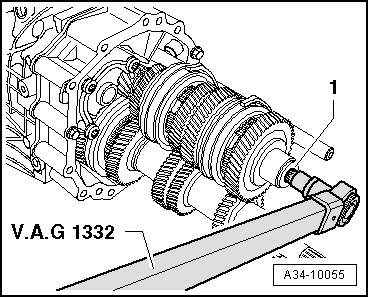

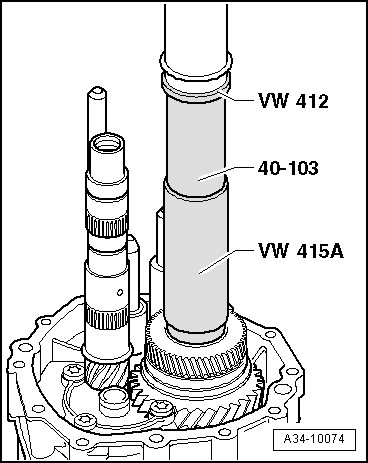

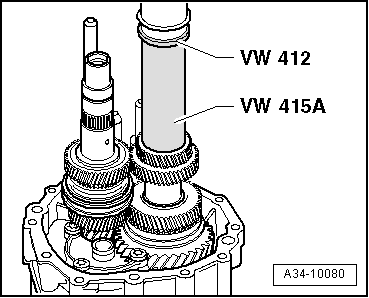

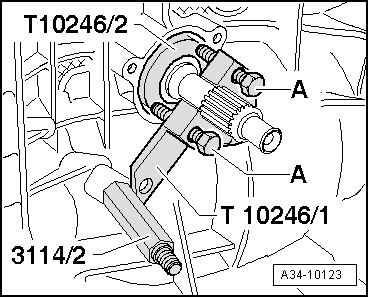

| If the input shaft or the gearbox housing have been renewed, you must first re-determine the thickness of the input shaft circlips → Chapter „Adjusting input shaft“. |

Note | t

| Lubricate all needle bearings with gear oil before fitting. |

| t

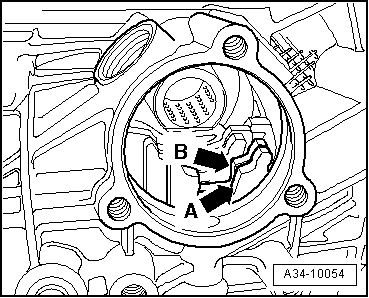

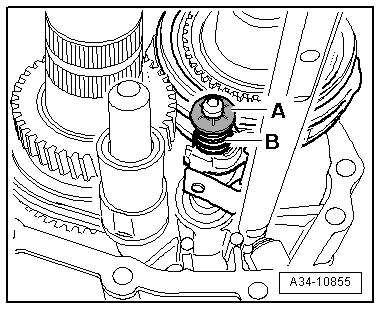

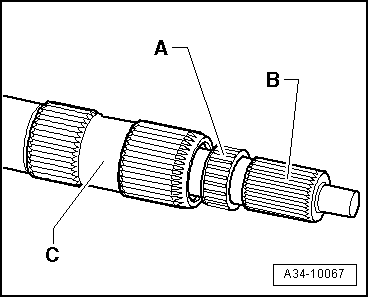

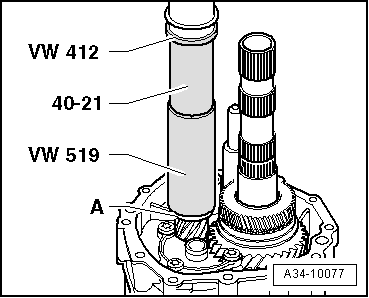

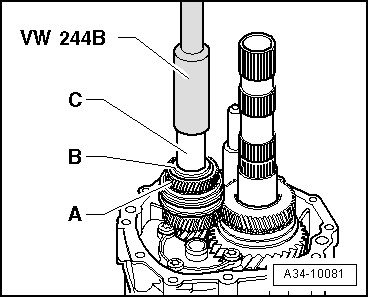

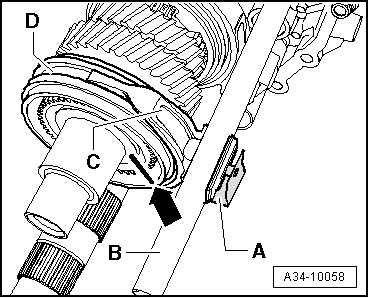

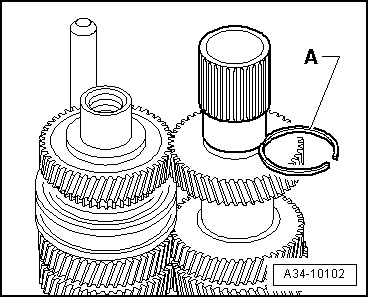

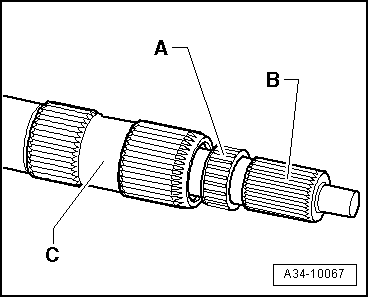

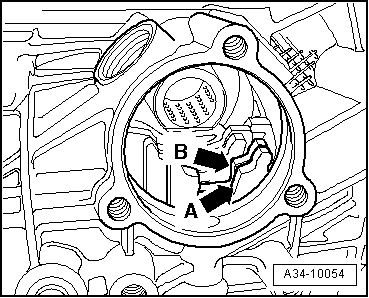

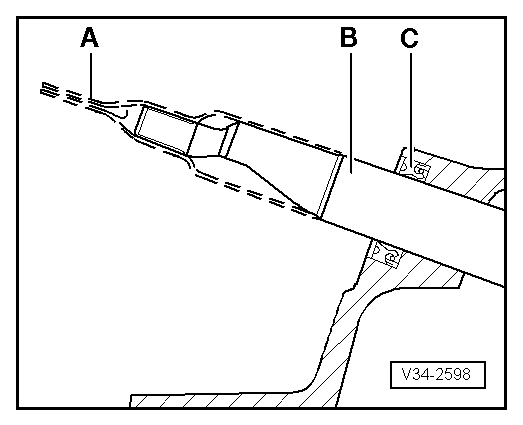

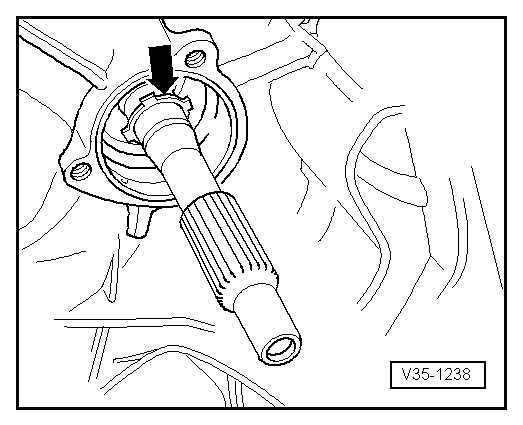

| Checking synchro-rings for wear → Fig.. |

| t

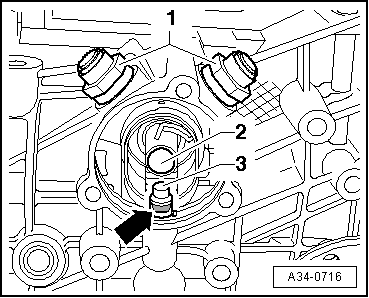

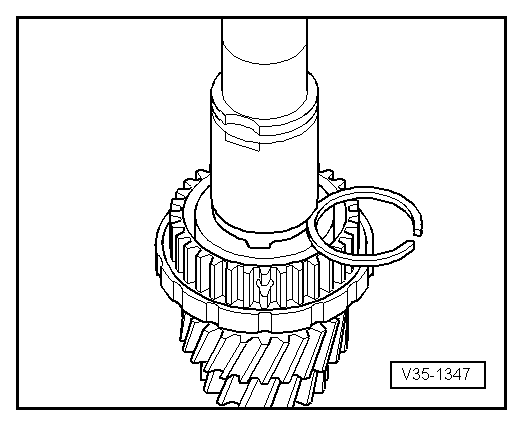

| Inserting spring in selector gear → Fig.. |

| t

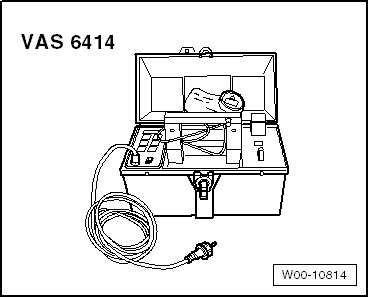

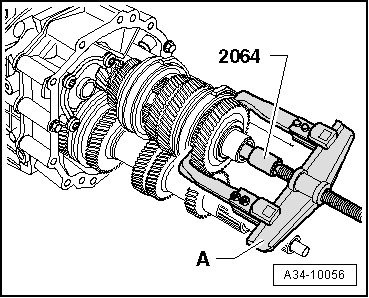

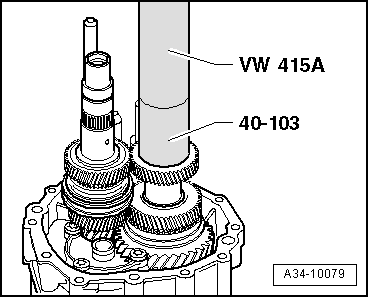

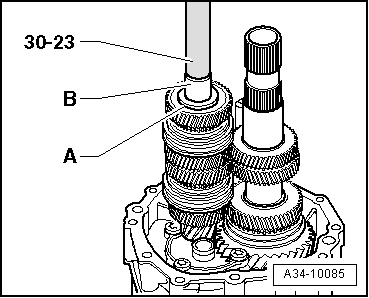

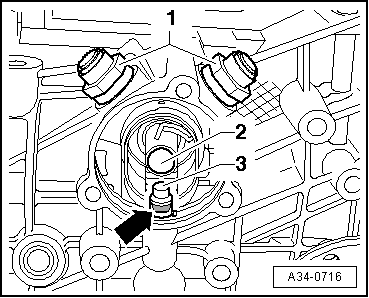

| Heat gear wheels, needle bearing inner races and synchro-hubs to approx. 100 °C (max.) before pressing on (wear protective gloves). |

| t

| The thread must be cleaned if a micro-encapsulated multi-point socket head bolt was previously fitted in the threaded hole of the input shaft. |

| –

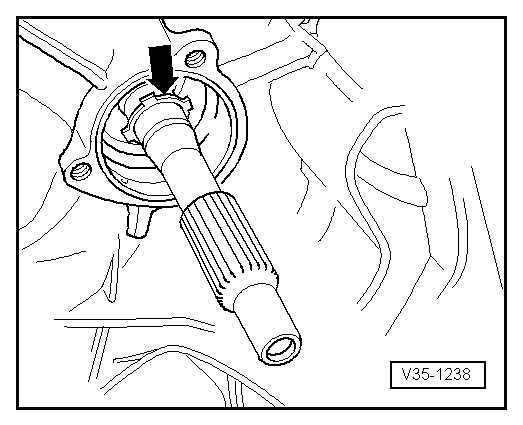

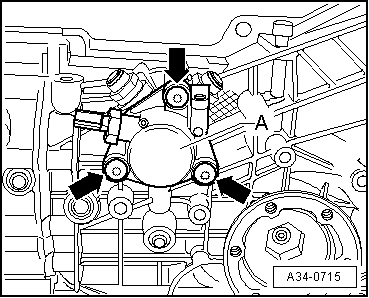

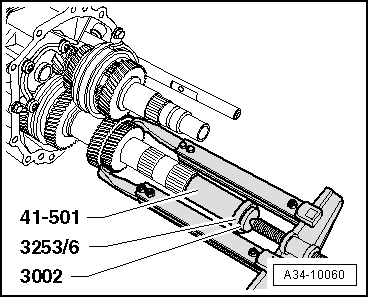

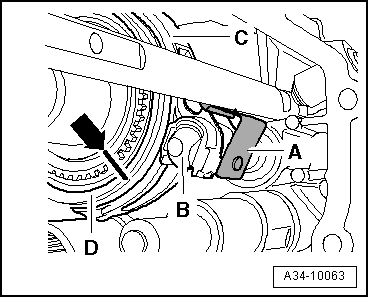

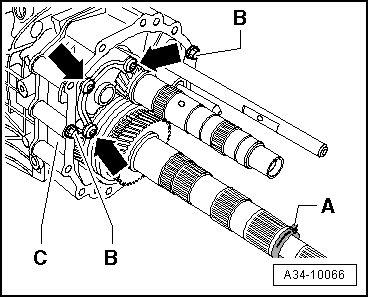

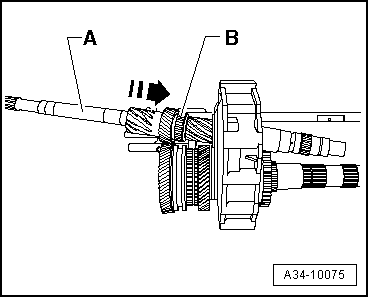

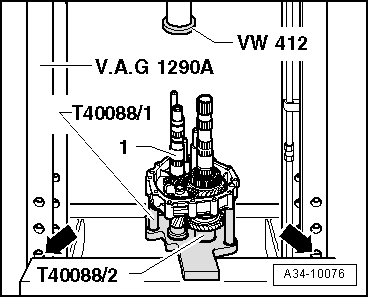

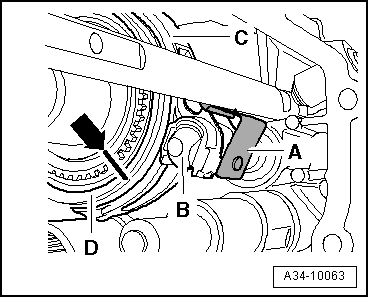

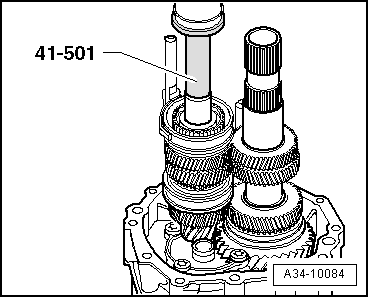

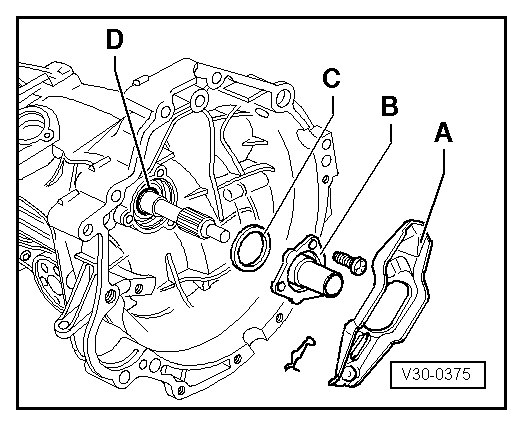

| Insert hollow shaft in bearing housing and selector fork for 1st and 2nd gear. |

| –

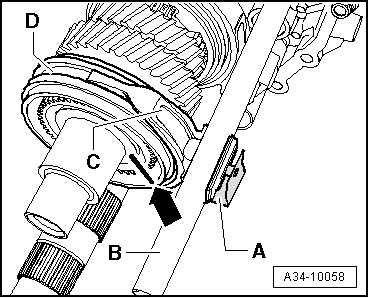

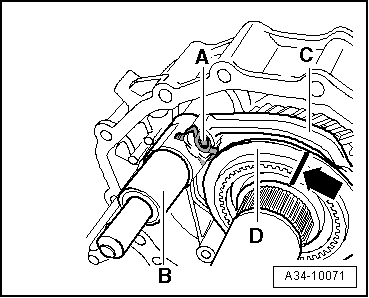

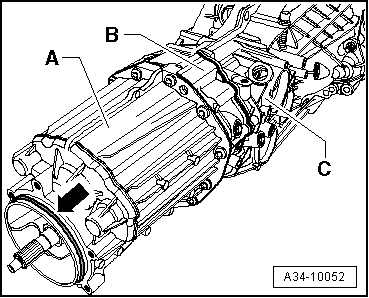

| Place reverse gear selector gear with needle bearing, spring and synchro-ring onto hollow shaft. |

| l

| The lugs on the synchro-ring should engage into the recesses in the selector gear. |

|

|

|

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Caution

Caution