A4 Mk2

| Removing gearbox - vehicles with 2.5 ltr. TDI engine |

| Special tools and workshop equipment required |

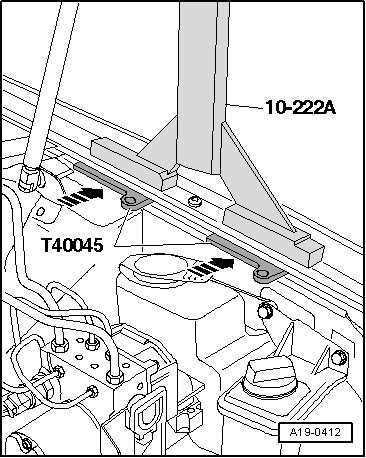

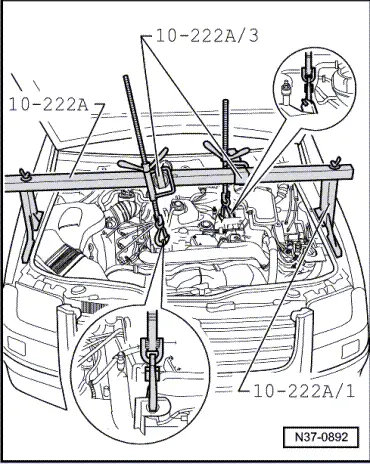

| t | Support bracket -10 - 222 A- |

| t | Rack -10 - 222 A /1- |

| t | Adapters -10 - 222 A /3- |

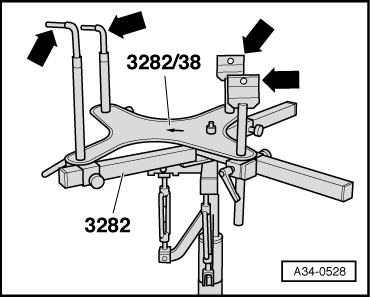

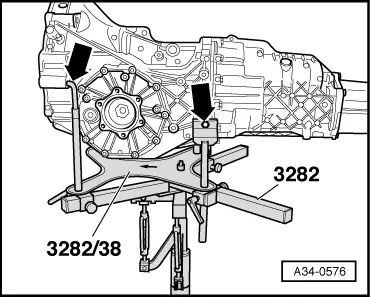

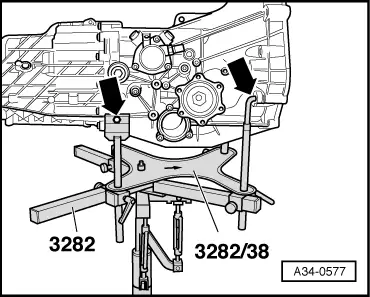

| t | Gearbox support -3282- |

| t | Adjustment plate -3282/38- |

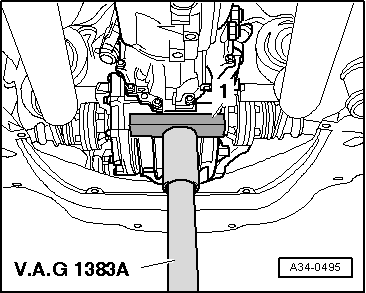

| t | Engine and gearbox jack -V.A.G 1383 A- |

|

|

Note

Note

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Note

Note

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Note

Note

|

|

|

|

|

|

Note

Note

|

|

|

|

|

|

Caution

Caution WARNING

WARNING