A4 Mk2

| Removing gearbox - vehicles with 2.0 ltr. TFSI engine |

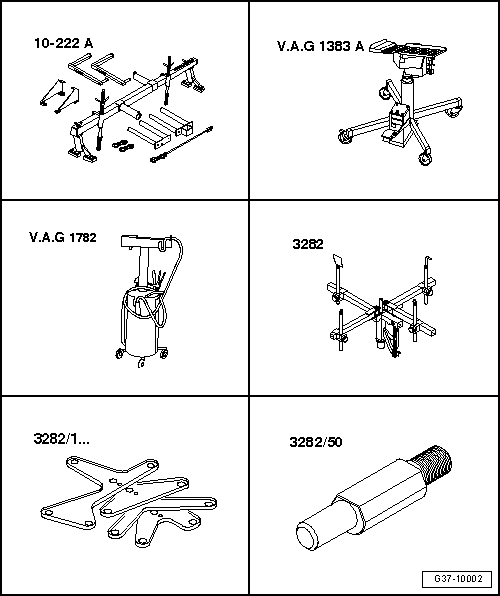

| Special tools and workshop equipment required |

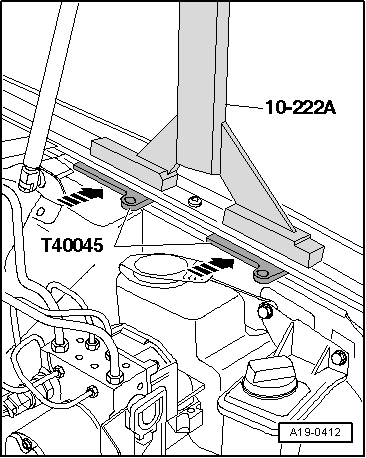

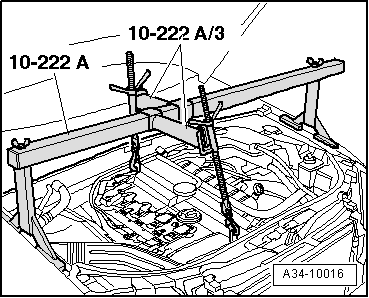

| t | Support bracket -10-222 A- |

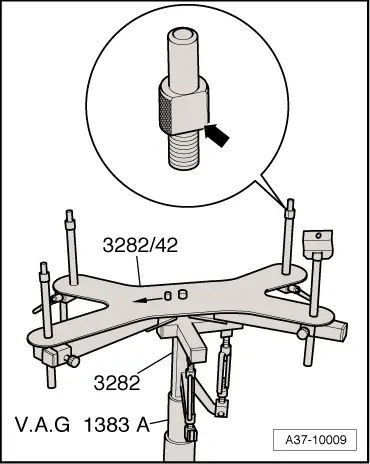

| t | Engine and gearbox jack -V.A.G 1383 A- |

| t | Used oil collection and extraction unit -V.A.G 1782- |

| t | Gearbox support -3282- |

| t | Adjustment plate -3282/48- |

| t | Pin -3282/50- |

|

|

|

|

Note

Note

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Note

Note |

|

|

|

|

|

|

|

Note

Note

Note

Note

|

|

Note

Note |

|

|

|

|

|

|

|

|

|

Note

Note

|

|

|

|

|

|

Note

Note

|

|

|

|

|

|

|

|

Note

Note

|

|

|

|

Caution

Caution