| Checking synchro-rings for 1st, 2nd and reverse gear for wear |

| –

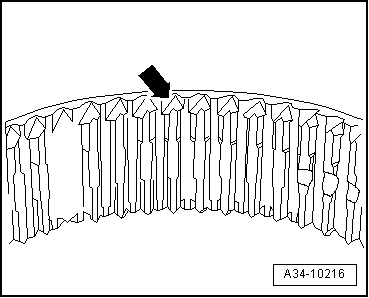

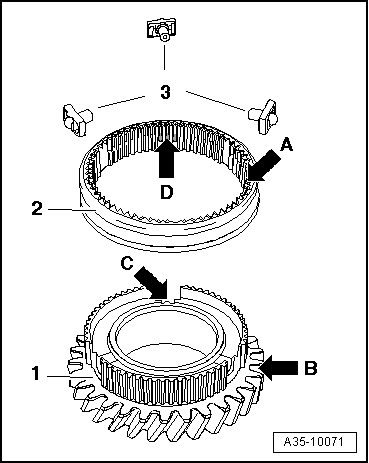

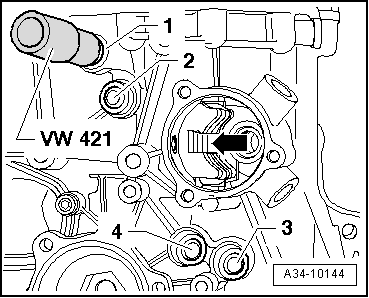

| Check outer friction surface on inner ring for scoring or visible traces of wear and renew if necessary. |

| –

| Check inner friction surface of synchro-ring for scoring or visible traces of wear and renew if necessary. |

| –

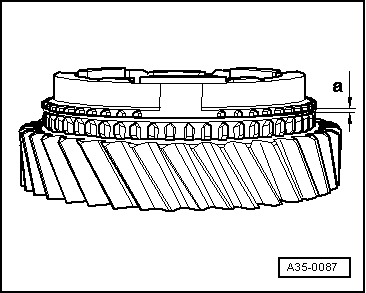

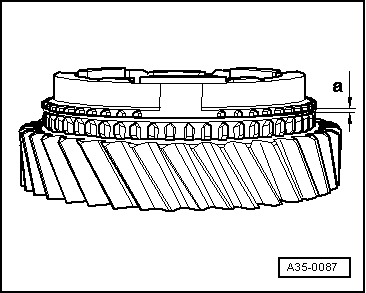

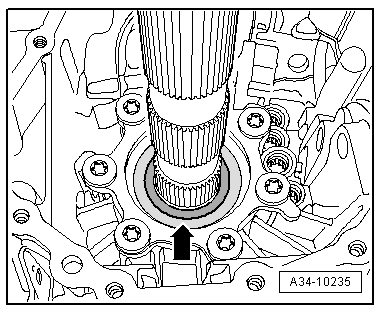

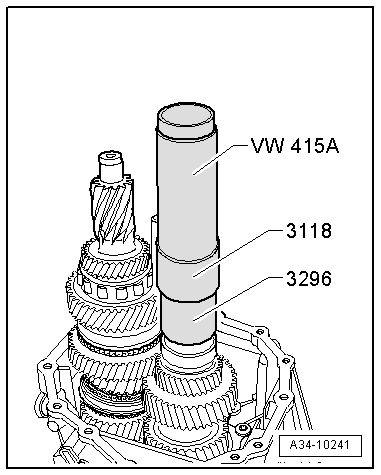

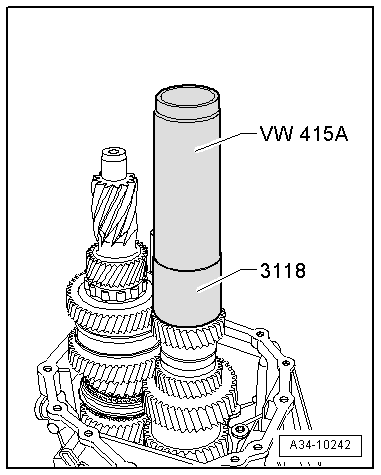

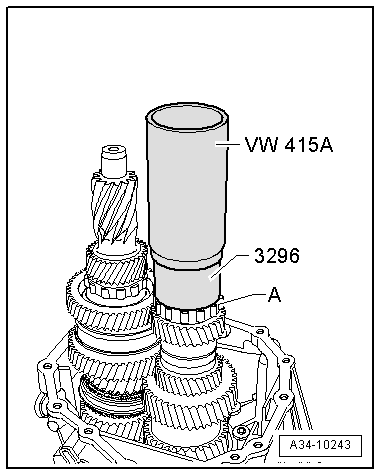

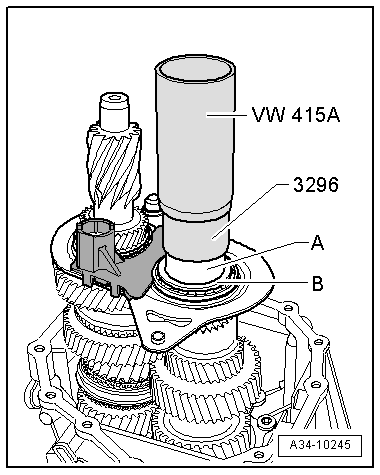

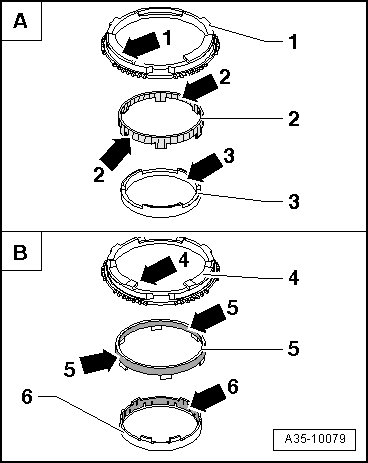

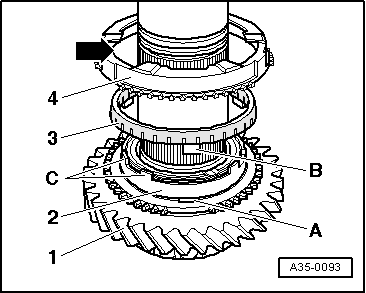

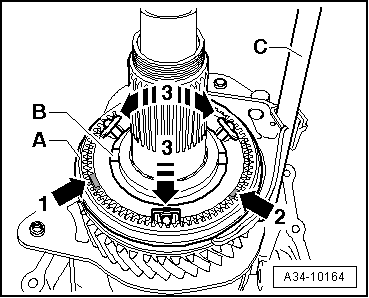

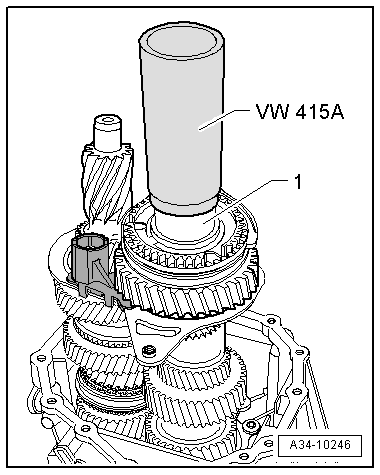

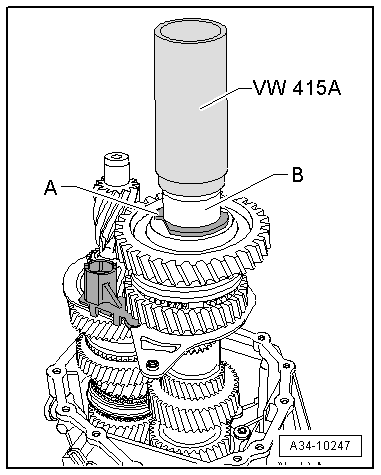

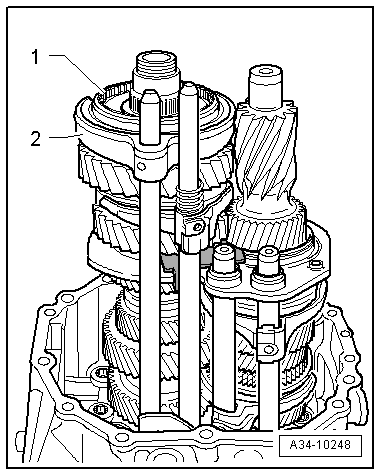

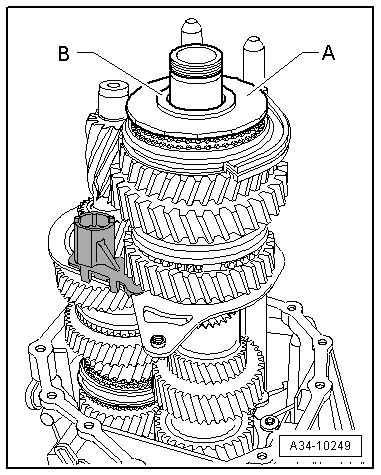

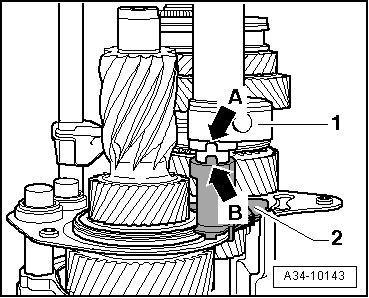

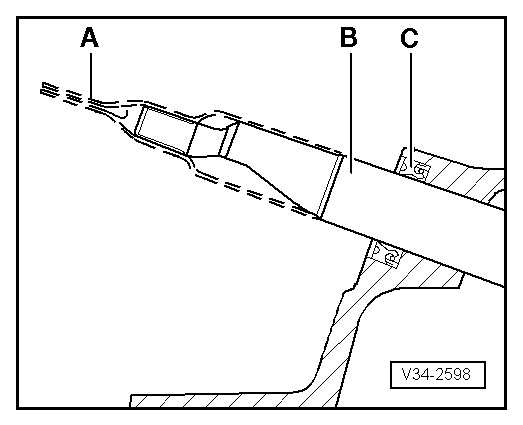

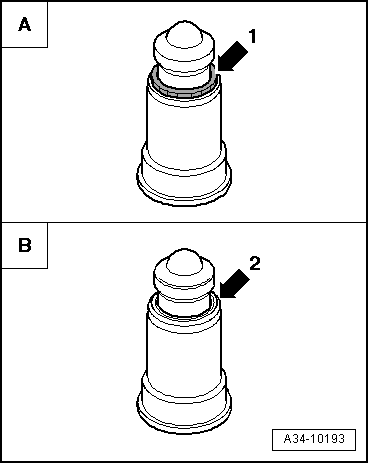

| Fit inner ring, intermediate ring and synchro-ring onto cone of selector gear/clutch unit and rotate rings to achieve proper seating. |

Note | To achieve proper seating, rotate synchro-rings approx. one turn while pressing down rings simultaneously. |

| –

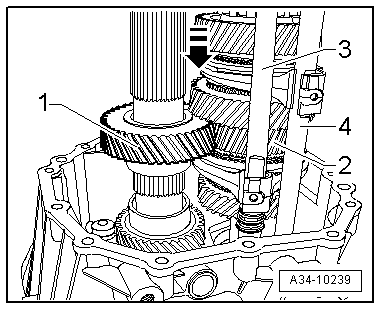

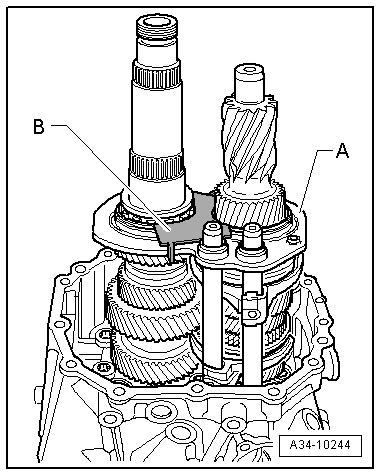

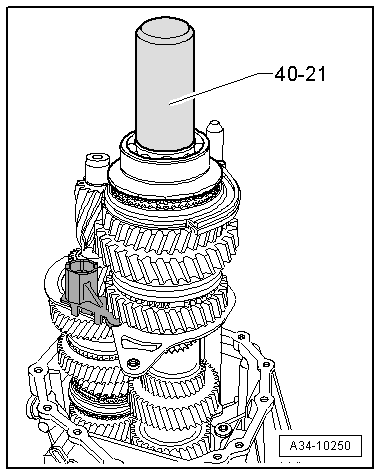

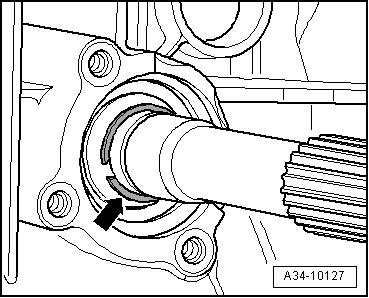

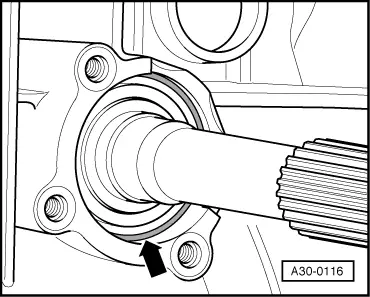

| Then measure gap -a- using a feeler gauge. |

|

|

|

Note

Note Note

Note

Note

Note Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

WARNING

WARNING